A kind of preparation method of aluminum bronze-stainless steel bimetallic composite material

A composite material and stainless steel technology, which is applied in the field of preparation of aluminum bronze-stainless steel bimetallic composite materials, can solve the problems of low interface bonding strength of bimetallic composite materials, achieve high bonding strength and prevent secondary production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

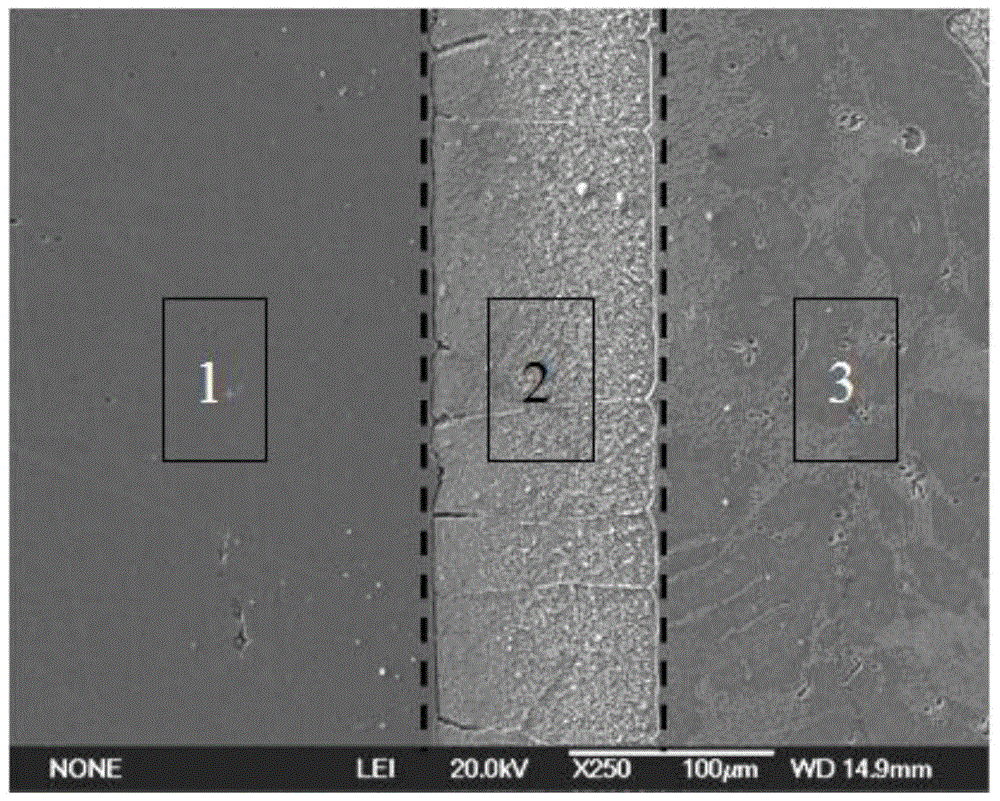

Image

Examples

Embodiment 1

[0026] Prepare the aluminum bronze QAl9-4 / stainless steel 1Cr18Ni9Ti bimetallic composite material, machine the stainless steel 1Cr18Ni9Ti into a cylinder with a size of Φ30mm×50mm, and prepare the aluminum bronze QAl9-4 material with a size of Φ30mm×60mm;

[0027] Soak stainless steel 0Cr18Ni9Ti in 10% nitric acid alcohol for pickling, pickle for 1min, then wash with alcohol and store in kerosene for later use;

[0028] Wash the pickled stainless steel 1Cr18Ni9Ti with alcohol to wash the surface oil stains, and then put it into a physical vapor deposition furnace for vacuuming. When the vacuum degree reaches 6.67×10 -2 After Pa, deposit CuNi10 material on the surface of stainless steel 1Cr18Ni9Ti for 15 minutes;

[0029] Put the surface deposited stainless steel 1Cr18Ni9Ti in the corundum crucible, and then put the aluminum bronze QAl9-4 material on the stainless steel 1Cr18Ni9Ti, put the corundum crucible ZRS-18Q microcomputer program-controlled vacuum high-temperature sinte...

Embodiment 2

[0031] Prepare the aluminum bronze QAl10-3-1.5 / stainless steel 0Cr17Ni14Mo2 bimetallic composite material, machine the stainless steel 0Cr17Ni14Mo2 into a Φ30mm×50mm cylinder, and prepare the aluminum bronze QAl10-3-1.5 material with a size of Φ30mm×60mm;

[0032] Soak stainless steel 0Cr17Ni14Mo2 in 10% nitric acid alcohol for pickling, pickling for 2 minutes, then wash with alcohol and store in kerosene for later use;

[0033] Rinse the pickled stainless steel 0Cr17Ni14Mo2 with alcohol to wash the oil stains on the surface, and then put it into a physical vapor deposition furnace for vacuuming. When the vacuum reaches 6.67×10 -2 After Pa, deposit CuNi15 material on the surface of stainless steel 0Cr17Ni14Mo2 for 20min;

[0034] Put the surface deposited stainless steel 0Cr17Ni14Mo2 in the corundum crucible, then put the aluminum bronze QAl10-3-1.5 material on the stainless steel 0Cr17Ni14Mo2, put the corundum crucible ZRS-18Q microcomputer program-controlled vacuum high-temp...

Embodiment 3

[0036] Prepare the aluminum bronze QAl10-4-4 / stainless steel 0Cr25Ni20 bimetallic composite material, machine the stainless steel 0Cr25Ni20 into a Φ30mm×50mm cylinder, and prepare the aluminum bronze QAl10-4-4 material with a size of Φ30mm×60mm;

[0037]Soak stainless steel 0Cr25Ni20 in 10% nitric acid alcohol for pickling, pickle for 3 minutes, then wash with alcohol and store in kerosene for later use;

[0038] Rinse the pickled stainless steel 0Cr25Ni20 with alcohol to wash the oil stains on the surface, and then put it into a physical vapor deposition furnace for vacuuming. When the vacuum reaches 6.67×10 -2 After Pa, deposit CuNi20 material on the surface of stainless steel 0Cr25Ni20 for 25 minutes;

[0039] Place the surface-deposited stainless steel 0Cr25Ni20 in the corundum crucible, then put the aluminum bronze QAl10-4-4 material on the stainless steel 0Cr25Ni20, put the corundum crucible ZRS-18Q microcomputer program-controlled vacuum high-temperature sintering furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com