Adjustable splicing mould bed

An adjustable tire frame technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to use the tire frame and adjust the tire frame, and achieve the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

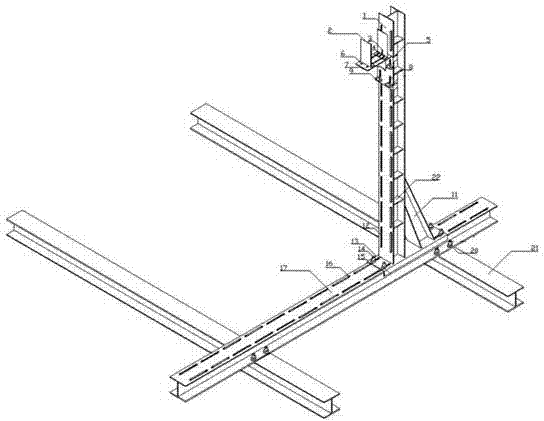

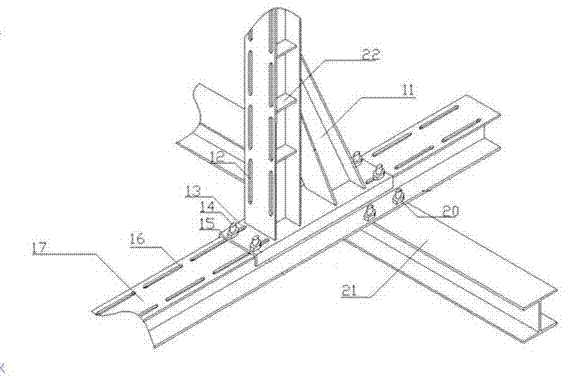

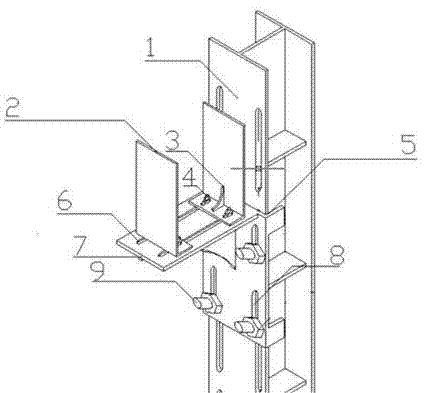

[0015] An adjustable assembled tire frame, the I-steel platform (21) is connected to an I-steel crossbar (17) through bolts (20), and the I-steel crossbar (17) is connected to a Root I-shaped steel pole (1), the back of channel steel I (15) is welded with the vertical pole (1), and the front of channel steel I (15) is stuck on the I-beam cross bar (17) with a notch. There are several oblong holes (16) on the beam cross bar (17), four oblong holes (13) are arranged on the channel steel I (15), and the oblong holes (16) of the I-beam cross bar (17) Length is 20cm, and the distance between every two oblong holes (16) is 5cm, and the length of the oblong hole (13) of channel steel I (15) is 6cm, utilizes the oblong hole ( 16) to change the lateral size of the tire frame. When adjusting the lateral size of the tire frame, unscrew the nut of the bolt (14), adjust the position of the screw in the bolt hole, and tighten the nut to fix the size after adjustment. The adjustable size in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com