Bottle cap assembling device and bottle cap assembling method

A technology for assembling devices and bottle caps, which is applied in the direction of assembly machines, metal processing, metal processing equipment, etc., to achieve the effect of improving quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

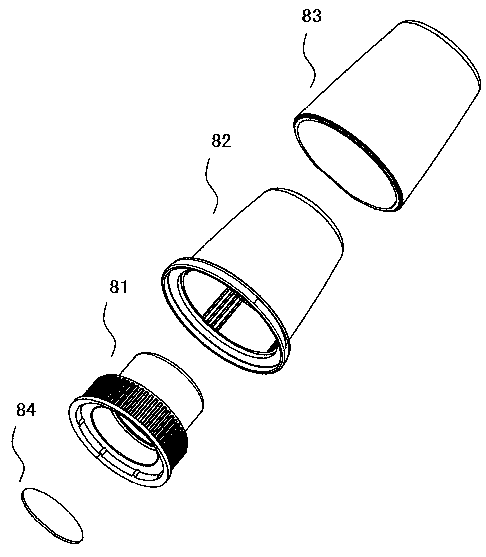

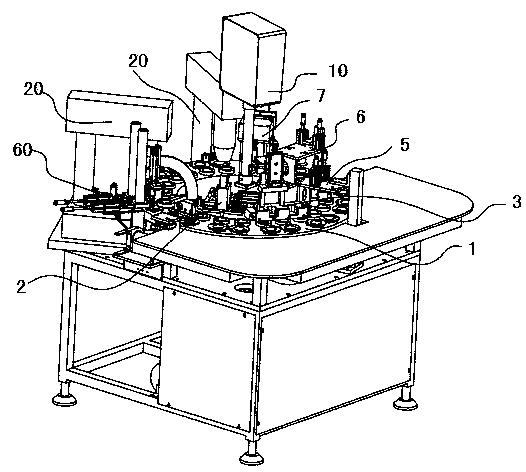

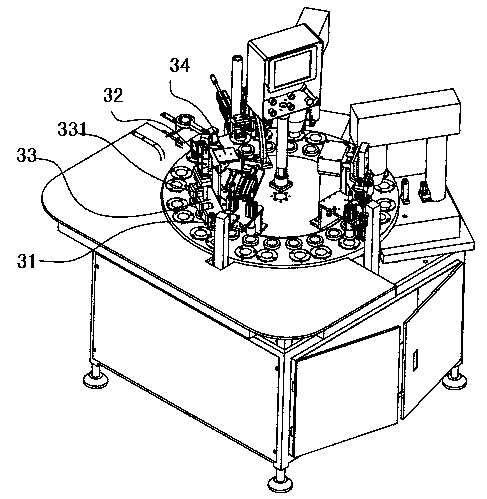

[0044] Please refer to Figure 1 to Figure 7 , the bottle cap assembly device in the figure mainly includes a disc-shaped workbench 1, a sleeve and mechanism, a welding mechanism, an automatic gasket machine 60, a blanking mechanism 70, and a control device 10.

[0045]Please refer to 18. The disc-shaped workbench 1 is the equipment often used in the automatic production line in the cosmetic bottle industry. It is evenly covered with two rows of cap placement holes 11 inside and outside. These cap placement holes 11 are used to place the middle cap 82 , outer cover 83; two of these cover placement holes 11 in each row form a group; wherein the cover placement hole 11 of the inner layer is used to place the middle cover 82, and the cover placement hole 11 of the outer layer is used to place the outer cover 83; work begins , the inner row adopts the manual method to place the middle cover 82 or use Figure 18 The vibrating plate 91 and the feeding track 92 shown in are fed, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com