Method for manufacturing antenna rib

A manufacturing method and rib technology, which are applied in the field of composite material preparation, can solve the problems of high cost, low product qualification rate, appearance and accuracy failing to meet design requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

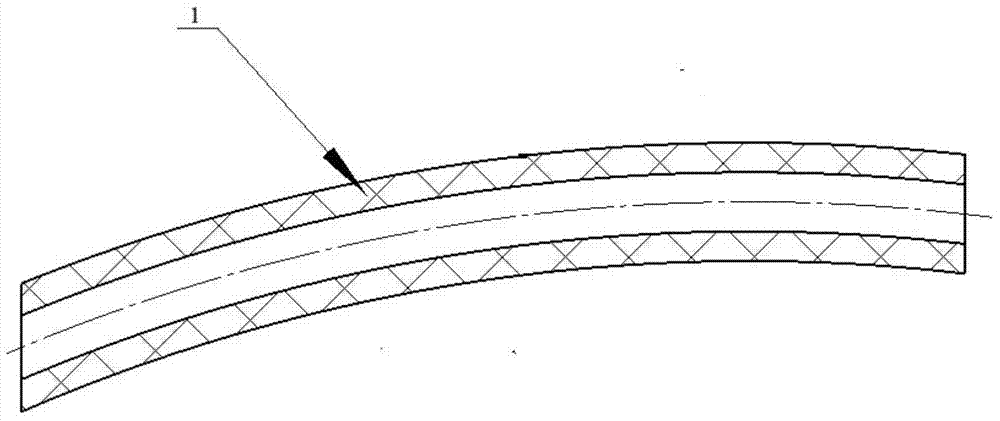

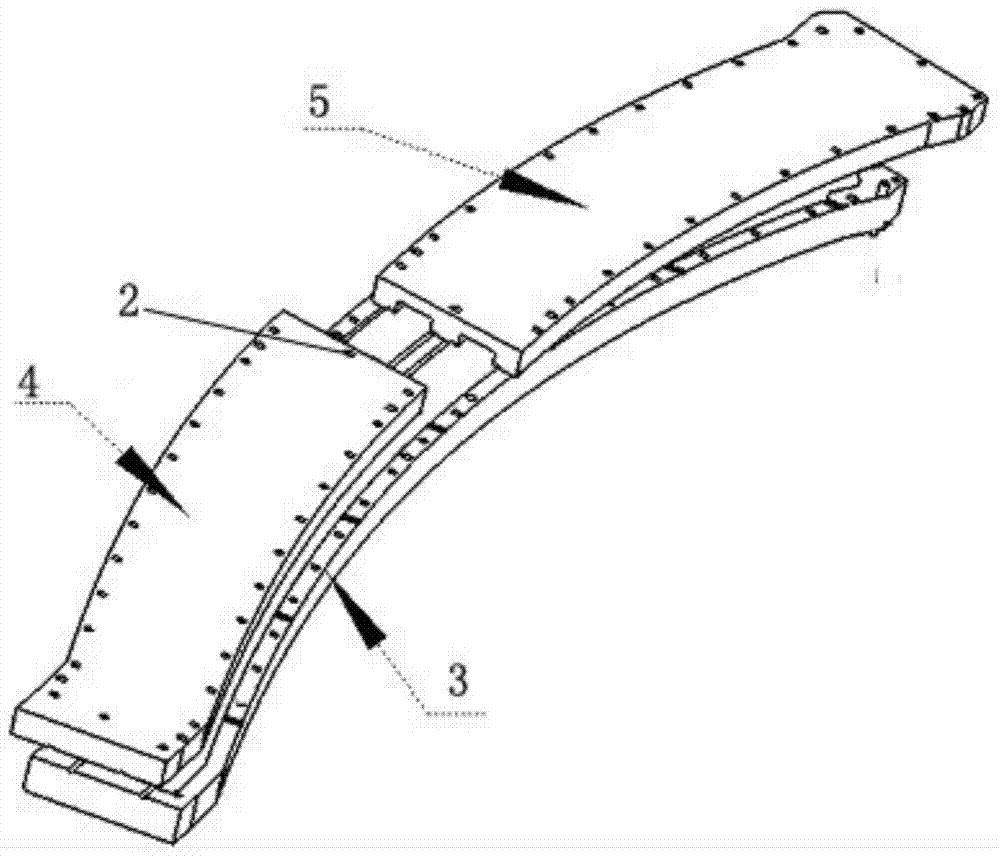

[0044] A method of manufacturing an antenna rib, comprising the following steps:

[0045] (1), the mold of prefabricated antenna rib is polished, and mold comprises upper die and lower die 3;

[0046] (2), adopt raw silica gel and pine to prepare core film and remove the burrs on the core film;

[0047] The core film is mainly used in preforming (equivalent to pulling out the core film after laying carbon fiber prepreg on the core film, and putting the preformed product into the mold cavity of the split die to form and solidify); the core film The design principle is to determine the outer diameter size according to the inner diameter of the product (because the product shape is known). Of course, it cannot be considered that the inner diameter of the product is the outer diameter of the core film, because the core film must be put on the nylon air bag in advance. , the thickness of the air bag is about 0.05mm. When preparing the shape of the product, it is necessary to rese...

specific Embodiment 2

[0073] It is basically the same as the specific embodiment, the only difference is:

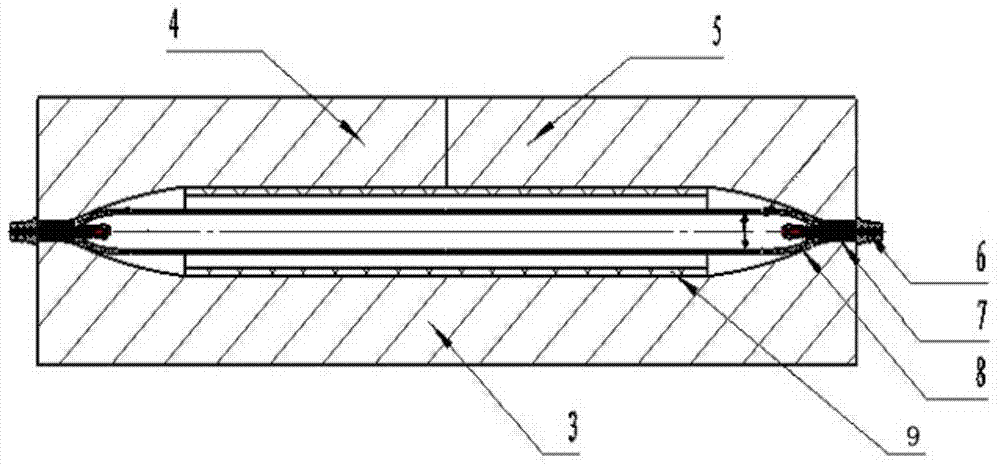

[0074] 1. In step (3), place the cut nylon air bag 8 in the coating agent and soak for 2 hours;

[0075] 2. Step (9) thermoforming comprises the following steps:

[0076] (91), the thermocompression molding machine is heated up to 128 ℃;

[0077] (92), one end of the trachea made of steel is connected to the air compressor, and the other end is connected to the nylon air nozzle 6, and the nylon air bag 8 is pressurized by the air compressor, and the pressure is 99pis;

[0078] (93), the step (8) mold is placed on the workbench of the thermocompression molding machine, and the thermocompression molding machine is clamped, and the pressure of the step (8) mold is pressurized by 9.9Mpa, and solidified for 123min.

specific Embodiment 3

[0079] It is basically the same as the specific embodiment, the only difference is:

[0080] 1, 1, step (3) the nylon air bag 8 that is cut through is placed in the coating agent soaking time is 3 hours;

[0081] 2. Step (9) thermoforming comprises the following steps:

[0082] (91), the thermocompression molding machine is heated up to 132 ℃;

[0083] (92), one end of the trachea made of steel is connected to the air compressor, and the other end is connected to the nylon air nozzle 6, and the nylon air bag 8 is pressurized by the air compressor, and the pressure is 102pis;

[0084] (93), the mold of step (8) is placed on the workbench of the thermocompression molding machine, and the thermocompression molding machine is clamped, and the pressure of step (8) mold is pressurized by 10.1Mpa, and solidified for 117min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ductility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com