Molding tool and molding method for zero-degree fiber bundles for R-angle reinforcement of composite material

A composite material and forming tooling technology, applied in the field of composite material manufacturing, can solve the problems of large floor space, narrow adaptability and high production cost, and achieve the effect of reducing floor space, improving production efficiency and rapid assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

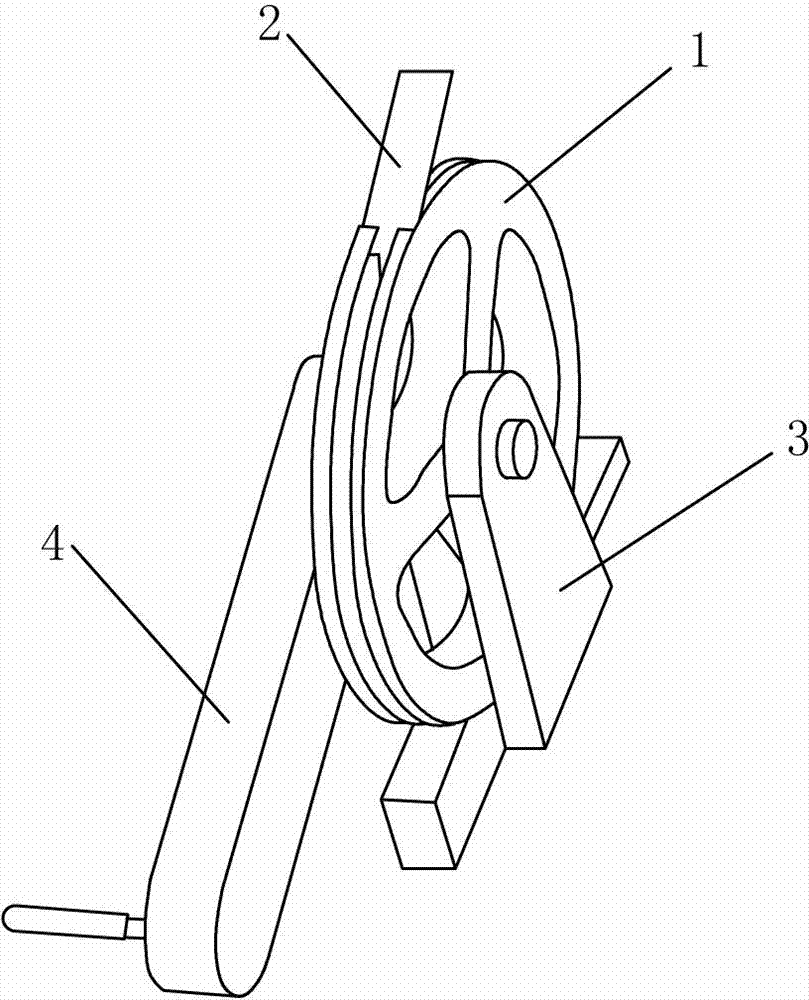

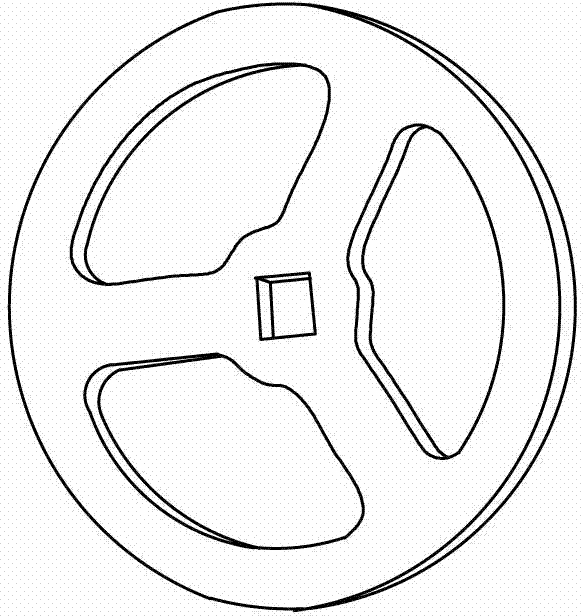

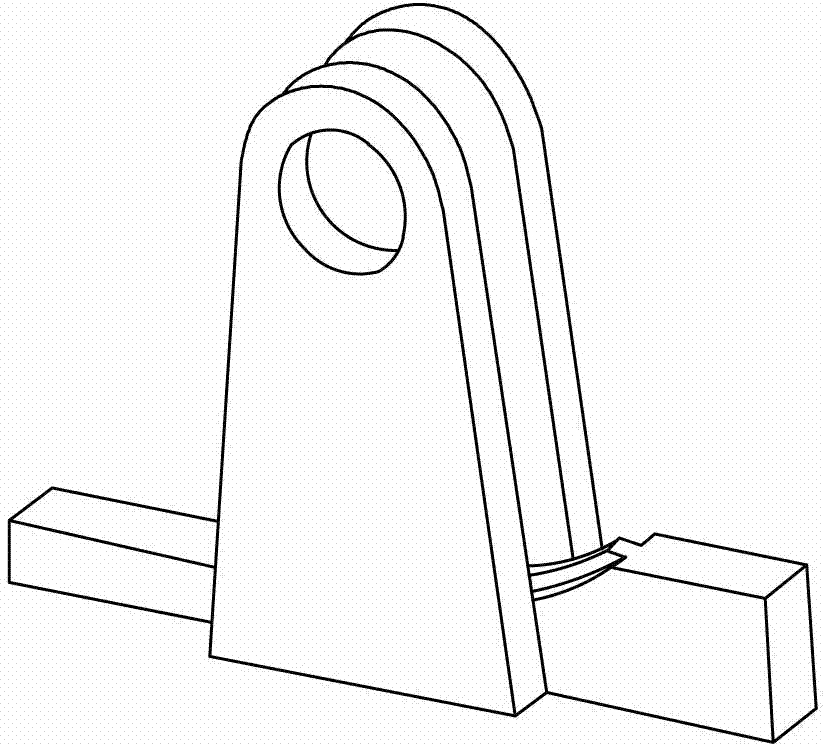

[0020] Such as Figure 1 to Figure 5 As shown, the zero-degree fiber bundle forming tool for composite material R angle reinforcement is composed of a forming die 1, a diaphragm 2, a fixed block 3 and a hand arm 4, wherein the forming die 1 is in the shape of a wheel and has a shaft hole in the center. The shaft on the hand rocker arm 4 is assembled and connected with the shaft hole on the forming die 1. The cylindrical surface of the forming die 1 is used as a profile, which is an R-angle filled area with zero-degree fiber bundles along the circumferential direction. The forming die 1 passes through the shaft The hole and the shaft are fixed on the fixed block 3, and the fixed block 3 is provided with a protruding profile, and the profile of the forming die 1 and the protruding profile on the fixed block 3 are combined to form a mold for the zero-degree fiber bundle to be pressed. Cavity, one end of diaphragm 2 is pointed.

[0021] The zero-degree fiber bundle forming method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com