A prefabricated concrete box girder comb plate fixing device

A technology of prefabricated concrete and fixtures, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve problems such as solder joint vibration, concrete leakage, comb plate deformation, etc., to achieve the effect of enhancing friction, improving quality, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below we will further elaborate on a prefabricated concrete box girder comb plate fixing device of the present invention in conjunction with the accompanying drawings and specific embodiments, in order to understand its structural composition and working mode more clearly, but it cannot be used to limit the present invention. protection scope of the invention.

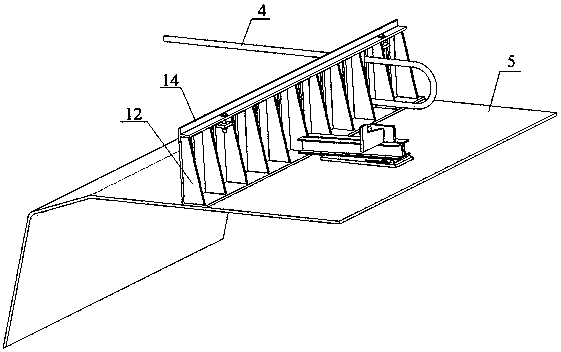

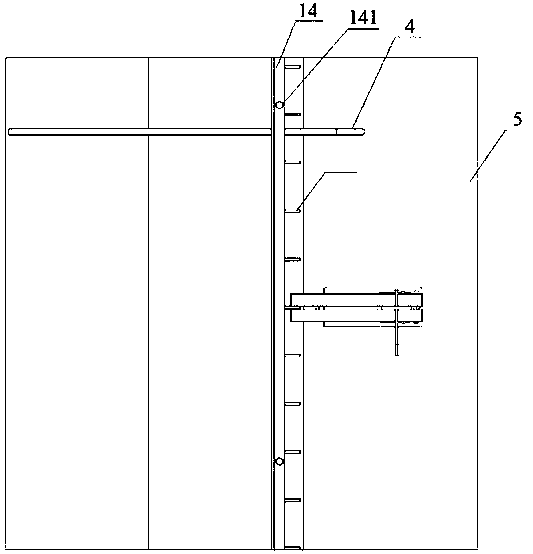

[0029] Such as Figure 1-10 As shown, the prefabricated concrete box girder comb plate fixing device in this embodiment includes a comb plate body 1, a limit device 2, a fixing device 3, a box girder surface layer steel bar 4 and a box girder formwork 5,

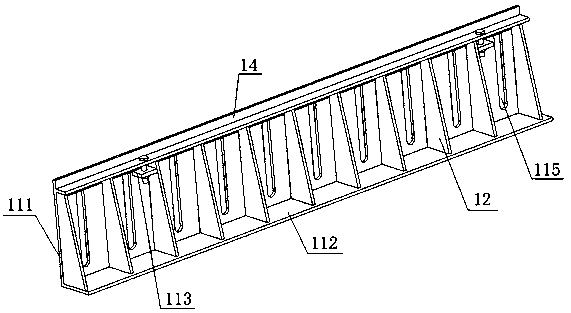

[0030] The comb plate body 1 is made up of a comb plate panel 11 and a rib plate 12. The comb plate panel 11 includes a horizontal plate 112 and a vertical plate 111 arranged in an L shape, and several rib plates 12 are welded on the horizontal plate 112. The bottom edge of the rib plate 12 is fixed on the horizontal plate 112, and one side of the rib plate 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com