Terpolymer dispersant for pesticide environmental protection formulation, preparation method and application

A technology of terpolymer and dispersant, applied in botany equipment and methods, chemicals for biological control, applications, etc., can solve the problem of difficult control of molecular weight distribution, achieve enhanced interaction force and improve disintegration Speed, increase the effect of branched chain structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

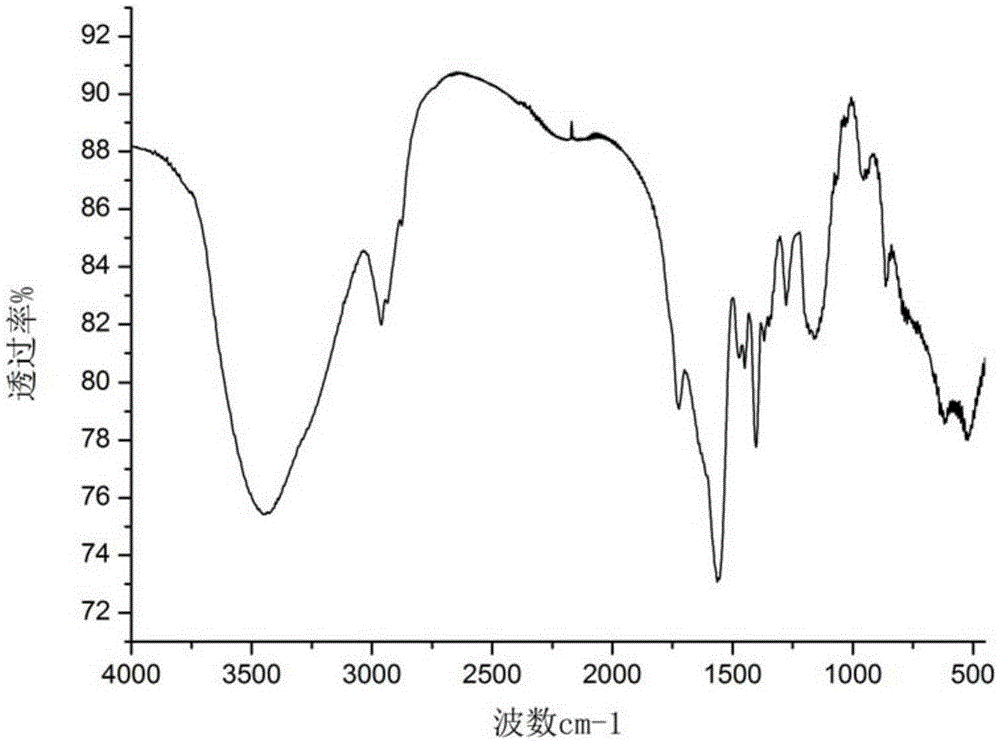

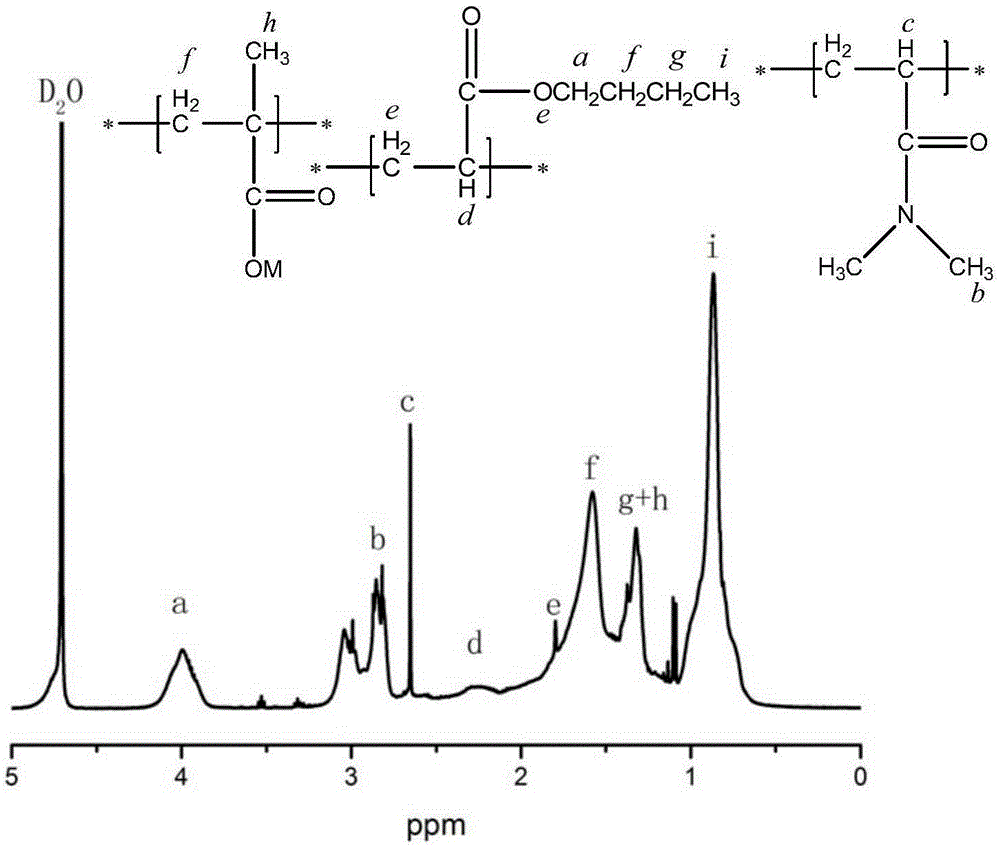

[0057] The preparation method of the terpolymer dispersant is as follows: in the presence of emulsifier, initiator and chain transfer agent, 20-70 parts by weight of methacrylic acid, 20-60 parts by weight of acrylic acid The butyl ester and 20-50 parts by weight of N,N-dimethylacrylamide undergo emulsion radical polymerization reaction, and then add alkali solution to obtain the terpolymer dispersant.

[0058] The method specifically includes the following steps:

[0059] (1) Add an emulsifier of 0.5-2% of the total mass of the monomers, an initiator of 1-5% of the total mass of the monomers and an appropriate amount of water into the reactor;

[0060] (2) 20-70 parts by weight of methacrylic acid, 20-60 parts by weight of butyl acrylate, 20-50 parts by weight of N,N-dimethylacrylamide, and 1-5% of the total mass of monomer chains The transfer agent is mixed evenly to make a mixed solution A;

[0061] (3) Add the mixed solution A dropwise to the reactor described in step 1)...

Embodiment 1

[0073] Add 200g of deionized water, 5g of ammonium persulfate and 2g of sodium dodecylsulfonate into a 500ml four-neck flask equipped with stirring, heating, thermometer, reflux, feeding and nitrogen protection devices, stir to raise the temperature to 70°C, and then drop Add a mixed liquid containing 50g of methacrylic acid, 30g of butyl acrylate, 20g of N,N-dimethylacrylamide and 2g of mercaptoacetic acid, dropwise for 30min, keep warm for 3h after the dropwise addition, and then cool down to 40 ℃, then add 30wt% NaOH solution to the product to adjust the pH value to 7, and spray dry to obtain a solid product.

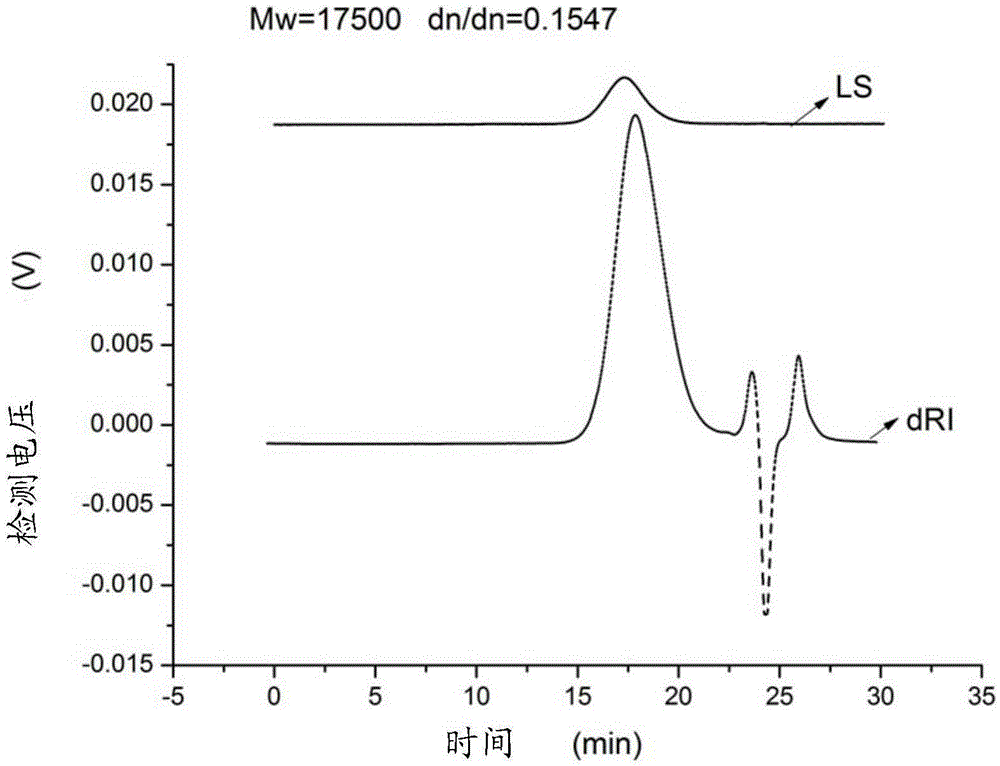

[0074] Gel chromatography coupled with laser light scattering, with 50mMNaH 2 PO 4 Solution and methanol mixture (70:30% (v / v)) was used as the mobile phase, polyethylene glycol 10,000 was used as the standard product, and the weight average molecular weight of the prepared copolymer dispersant was determined to be 17,500. image 3 Shown is the gel chromatogram of ...

Embodiment 2

[0090] Add 200 g of deionized water, 4 g of potassium persulfate and 0.5 g of sodium dodecylbenzenesulfonate into a 500 ml four-neck flask equipped with stirring, heating, thermometer, reflux, feeding and nitrogen protection devices, and stir to raise the temperature to 90 ° C. Then add dropwise the mixed liquid containing 30g of methacrylic acid, 50g of butyl acrylate, 20g of N,N-dimethylacrylamide, and 1g of ethyl mercaptoacetate for 20min, and keep the temperature for 2h after the dropwise addition, and then The temperature was lowered to 50° C., and then ammonia solution was added to the product to adjust the pH value to 7, and the product was spray-dried to obtain a solid product.

[0091] Gel chromatography coupled with laser light scattering, with 50mMNaH 2 PO 4 Solution and methanol mixture (70:30% (v / v)) was used as the mobile phase, polyethylene glycol 10,000 was used as the standard product, and the weight average molecular weight of the prepared copolymer dispersa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| suspension rate | aaaaa | aaaaa |

| suspension rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com