Powder binding agent for glass fiber felt

A powder binder, glass fiber mat technology, applied in textiles, papermaking, non-woven fabrics, etc., to achieve the effects of stable quality, increased strength, and increased branched chain structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Put 74.1 g (0.5 mol) of phthalic anhydride, 38.1 g (0.5 mol) of propylene glycol, 157.6 g (0.4 mol) of propylene oxide adduct of bisphenol A, and 24.1 g of trimethylolethane into a four-necked flask. g (0.15mol), heat up to 180°C, react under nitrogen protection for 3h, slowly raise the temperature to 200°C and continue the reaction until the acid value drops below 20mg KOH / g. Then cool down to 150°C, add 49.1g (0.5mol) of maleic anhydride, slowly raise the temperature to 200°C, and measure its acid value to be less than 20mg KOH / g, add 2g of polyvinyl alcohol (model: polyvinyl alcohol 1799), stir well and pour After cooling, the product is crushed into powder after cooling to obtain a powder binder for glass fiber mat. Sprinkle the powder manually twice with 3% addition (that is, manually sprinkle the powder binder on the chopped glass fiber to make a felt, and the weight of the powdered binder accounted for 3% of the weight of the chopped glass fiber), set Bake at 18...

Embodiment 2-5

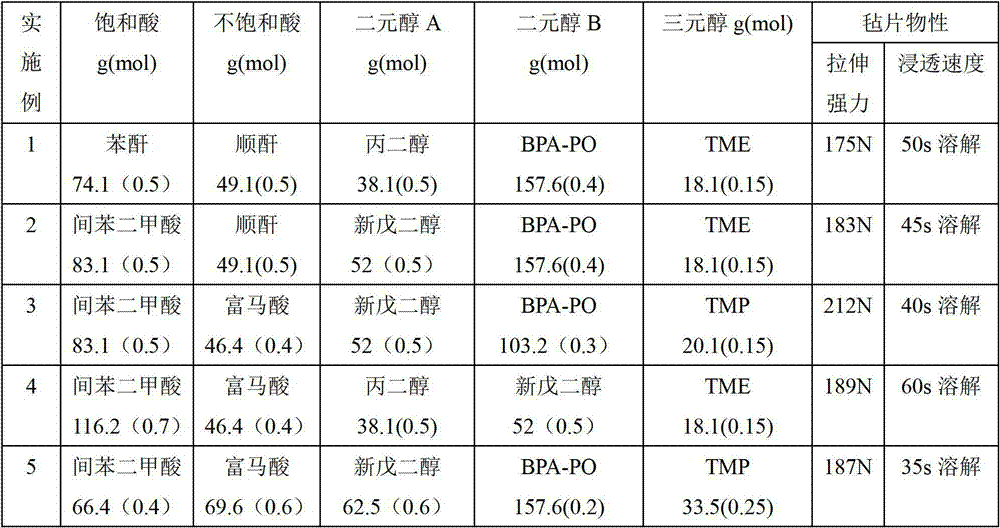

[0038] The operation method of each embodiment is identical with embodiment 1, and the difference of formula is shown in Table 1:

[0039] Table 1

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com