A kind of conductive PVC shoe material and manufacturing method thereof

A shoe material, conductive metal technology, applied in footwear, applications, clothing and other directions, can solve the problem of PVC shoe material not having conductive function, can not eliminate human body static electricity, damage electronic components and other problems, to provide plasticity and fluidity, The effect of improving compatibility and increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

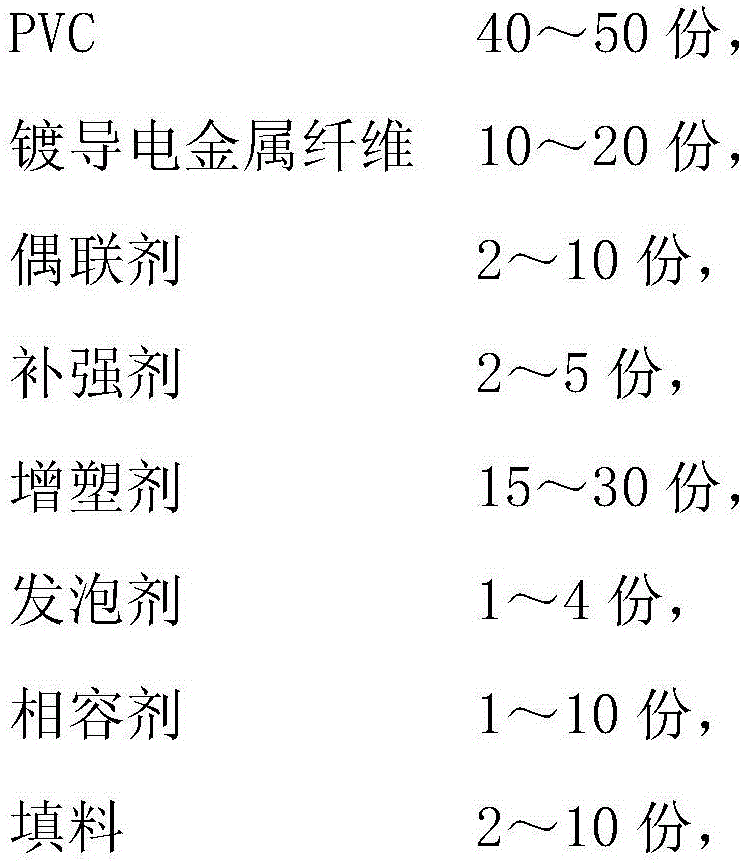

[0029] A kind of conductive PVC shoe material, its parts by weight consist of:

[0030]

[0031] Its manufacturing method comprises the following steps:

[0032] (1) Pretreatment: Stir the conductive metal fiber and the coupling agent evenly according to the formula and then dry;

[0033] (2) Mixing: Mix PVC and plasticizer according to the formula at a temperature of 150°C, then add other components in the formula and mix to obtain a uniformly mixed material;

[0034] (3) extrusion: the material obtained in step (2) is added to an extruder, and extruded to obtain conductive PVC pellets;

[0035] (4) Injection molding: adding the conductive PVC pellets obtained in step (3) to an injection molding machine, and injection molding to obtain conductive PVC shoe material.

Embodiment 2

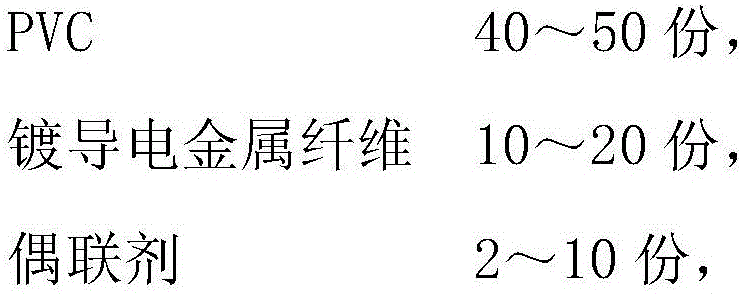

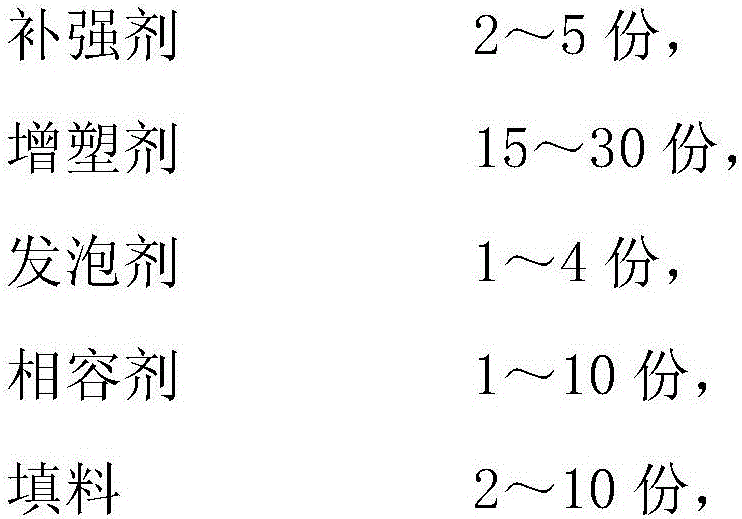

[0037] A kind of conductive PVC shoe material, its parts by weight consist of:

[0038]

[0039] Its manufacturing method comprises the following steps:

[0040] (1) Pretreatment: Stir the conductive metal fiber and the coupling agent evenly according to the formula and then dry;

[0041] (2) Mixing: Mix PVC and plasticizer according to the formula at a temperature of 55°C, then add other components in the formula and mix to obtain a uniformly mixed material;

[0042] (3) extrusion: the material obtained in step (2) is added to an extruder, and extruded to obtain conductive PVC pellets;

[0043] (4) Injection molding: adding the conductive PVC pellets obtained in step (3) to an injection molding machine, and injection molding to obtain conductive PVC shoe material.

Embodiment 3

[0045] A kind of conductive PVC shoe material, its parts by weight consist of:

[0046]

[0047] Its manufacturing method comprises the following steps:

[0048] (1) Pretreatment: Stir the conductive metal fiber and the coupling agent evenly according to the formula and then dry;

[0049] (2) Mixing: Mix PVC and plasticizer according to the formula at a temperature of 100°C, then add other components in the formula and mix to obtain a uniformly mixed material;

[0050] (3) extrusion: the material obtained in step (2) is added to an extruder, and extruded to obtain conductive PVC pellets;

[0051] (4) Injection molding: adding the conductive PVC pellets obtained in step (3) to an injection molding machine, and injection molding to obtain conductive PVC shoe material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com