A kind of acidic aggravated fracturing fluid and its preparation method and application

A fracturing fluid and acid technology, applied in the field of fracturing fluid, can solve the problems of aggravating the long-term development of the fracturing fluid system, unavoidable secondary damage to the formation, large price fluctuations, etc. The effect of improving temperature resistance and shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

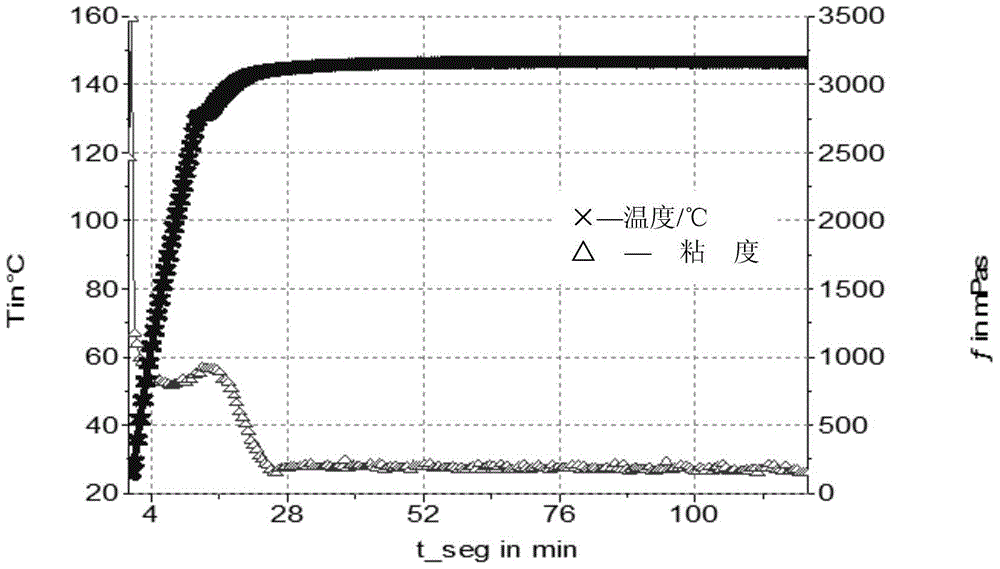

Examples

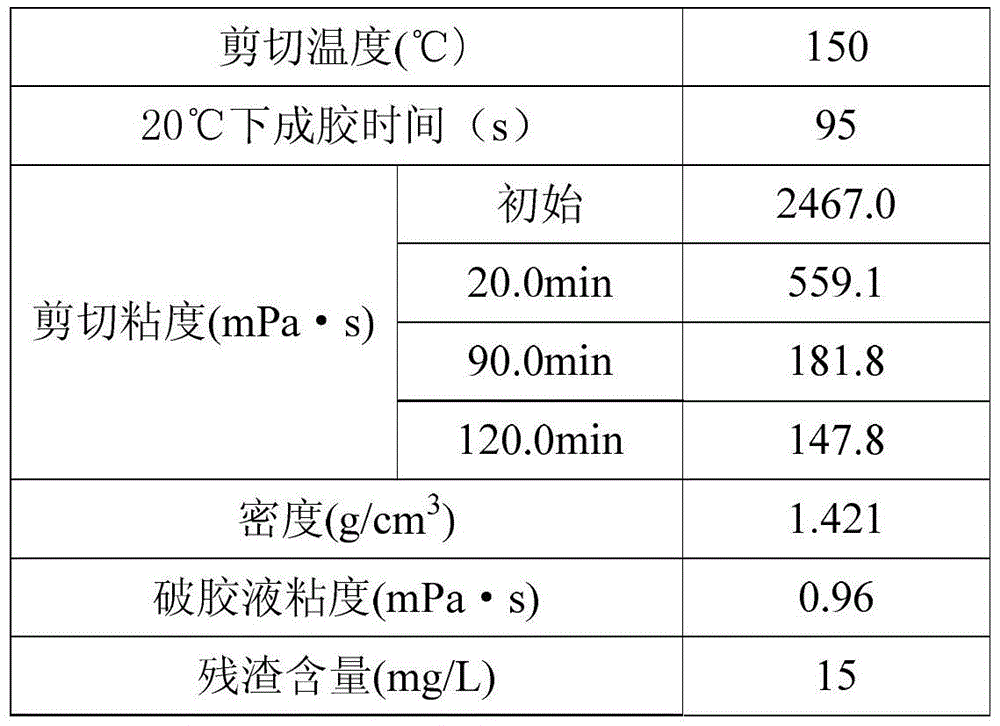

Embodiment 1

[0041] 30% weighting agent sodium citrate, thickener (acrylamide and 2-acrylamide-2-methylpropanesulfonic acid mass ratio is 1:1 synthetic polymer viscosity-average molecular weight is about 12 million. Wherein polymerization temperature is at 12 ℃, reaction time 3-5 hours.) 0.7%, pH regulator sulfamic acid 0.05%, aldehyde crosslinking agent hexamethylenetetramine 0.25%, phenolic crosslinking agent resorcinol 0.015%; Accelerator triethylenediamine 0.02%, demulsifier SP16 90.1%, iron ion stabilizer EDTA disodium 1.0%, ammonium persulfate 0.05%, sodium nitrite 0.025% and the balance of water are mixed to prepare the present invention of fracturing fluid. Its preparation method is:

[0042] (1) Preparation of base liquid: Add 60g of weighting agent, 2g of iron ion stabilizer, 0.1g of pH regulator and 0.2g of demulsifier SP1690.2g into 127.3g of water, slowly add 1.4g of thickener under stirring, continue to Stir for 2 hours until the polymer is fully dissolved;

[0043] (2) Pr...

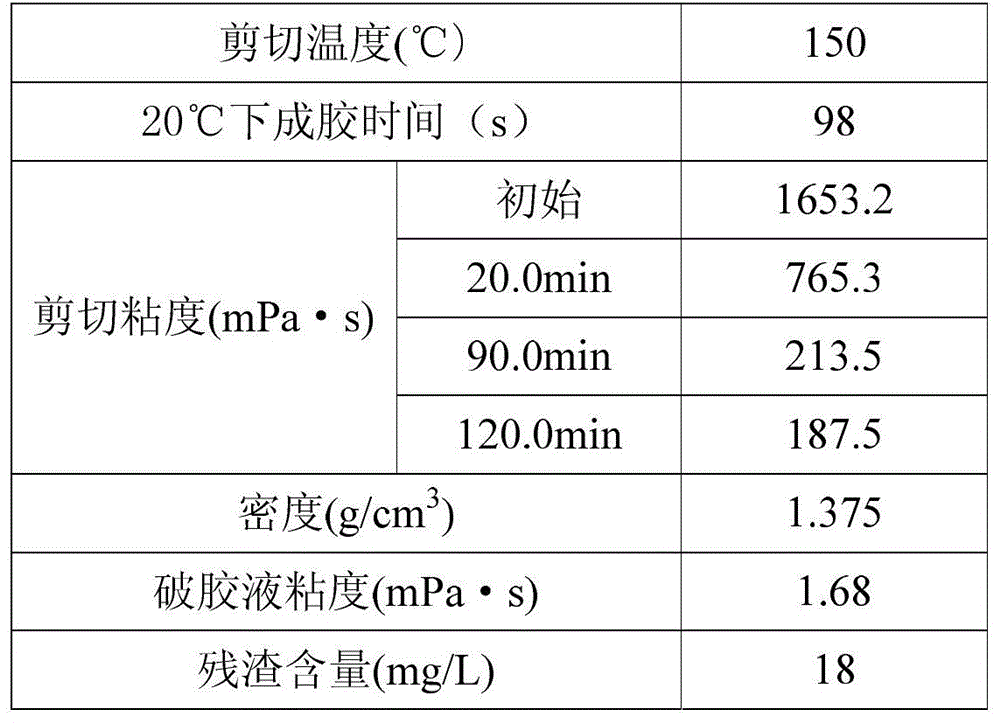

Embodiment 2

[0049] The weighting agent sodium citrate 20%, thickener (acrylamide and 2-acrylamide-2-methylpropanesulfonic acid mass ratio is 1:1 synthetic polymer viscosity average molecular weight is about 12 million. Polymerization temperature is at 12 ℃ , reaction time 3-5 hours.) 0.8%, pH regulator sulfamic acid 0.1%, aldehyde crosslinking agent hexamethylenetetramine 0.2%, phenolic crosslinking agent resorcinol 0.01%; crosslinking promotion The fracturing fluid of the present invention is prepared by mixing 0.1% triethylenediamine, 0.1% demulsifier SP1690.1%, 0.5% iron ion stabilizer citric acid, 0.1% ammonium persulfate, 0.05% sodium nitrite and the rest of water.

[0050] Its preparation method is:

[0051] (1) Base liquid preparation: Add 40g of weighting agent, 1g of iron ion stabilizer, 0.2g of pH regulator and 0.2g of demulsifier SP1690.2g into 138g of water, slowly add 0.6g of thickener under stirring, and continue stirring after adding 2h, until the polymer is fully dissolve...

Embodiment 3

[0058] The weighting agent sodium citrate 25%, thickener (acrylamide and 2-acrylamide-2-methylpropanesulfonic acid mass ratio is 1:1 synthetic polymer viscosity average molecular weight is about 12 million. Polymerization temperature is at 12 ℃ , reaction time 3-5 hours.) 0.75%, pH regulator sulfamic acid 0.075%, aldehyde crosslinking agent hexamethylenetetramine 0.1%, phenolic crosslinking agent resorcinol 0.005%; crosslinking promotion The fracturing fluid of the present invention is prepared by mixing 0.05% triethylenediamine, 90.2% demulsifier SP16, 0.75% ferric acetate stabilizer, 0.1% ammonium persulfate, 0.025% sodium nitrite and the rest of water.

[0059] Its preparation method is:

[0060] (1) Base liquid preparation: Add 50g of weighting agent, 1.5g of iron ion stabilizer, 0.15g of pH regulator and 0.4g of demulsifier SP1690.4g into 126.45g of water, and slowly add 1.5g of thickener under stirring. Continue to stir for 2 hours until the polymer is fully dissolved; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com