A method for strengthening aluminum alloys by using electromagnetic field aging

A technology of aging strengthening and aluminum alloy, which is applied in the field of electromagnetic field heat treatment of non-ferrous metal materials, can solve the problems that affect the implementation of industrialization and the difficulty of obtaining a stable and strong magnetic field, and achieve shortening of aging precipitation time, obvious improvement of structure and performance, and easy access Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

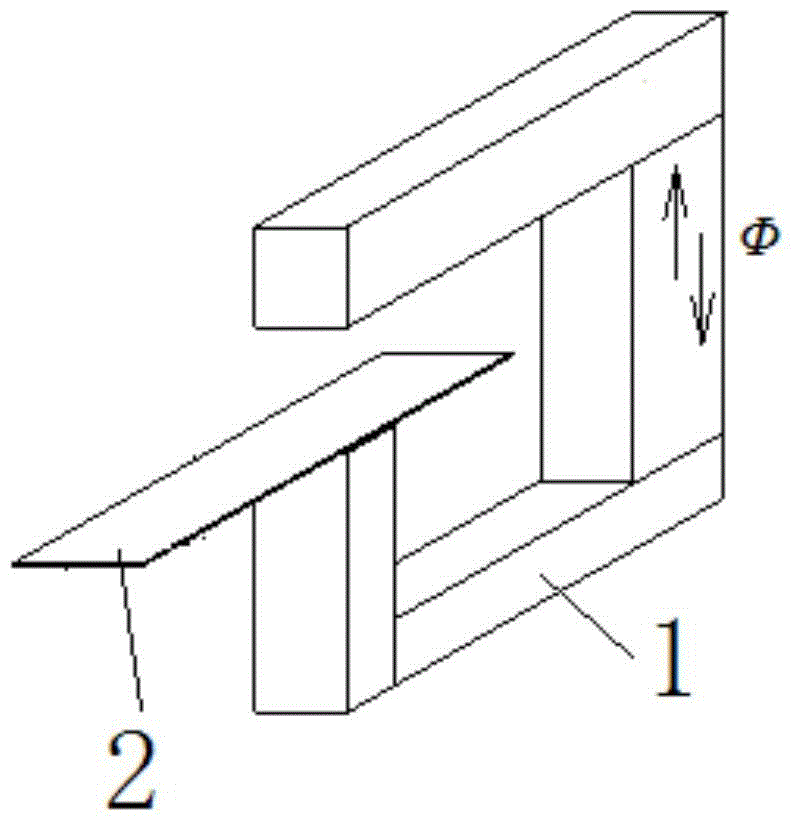

[0040] The 2219 aluminum alloy cold-rolled sheet with a thickness of 4mm was made into two groups of tensile samples according to HB5143-96. A group of samples were kept in a solid solution furnace at 500-545°C for 45 minutes, quickly quenched after taking out the samples, and then placed in an aging furnace at 175°C for 3 hours. The first two steps of another group of samples are the same, but an alternating magnetic field is applied in the aging furnace, and the frequency and intensity of the magnetic field are 40-60Hz and 40-100mT, respectively. The direction of the magnetic field is as figure 1 As shown, the aluminum alloy cold-rolled sheet is placed transversely in the magnetic force field so that it cuts the magnetic force lines.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com