Ultra-high energy level dynamic compaction and displacement compatible construction technology

A technology of construction technology and energy level, which is applied in basic structure engineering, soil protection, construction, etc., can solve problems such as inapplicable foundation deformation requirements, and achieve the effect of improving the bearing capacity of foundations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

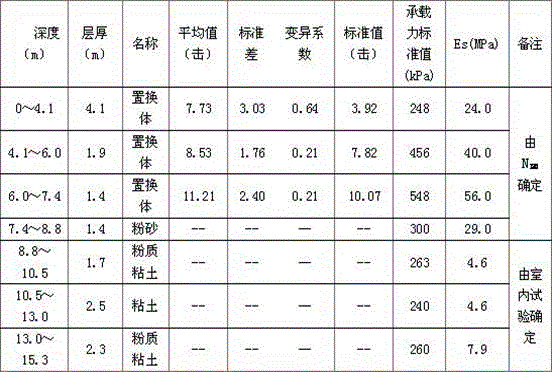

[0040] The foundations treated with ultra-high-energy level dynamic compaction and replacement technology are all extremely weak foundations. In order to avoid the possibility of the rammer being stuck in the mud and unable to be pulled out when the site is directly subjected to ultra-high-energy level dynamic compaction due to the low bearing capacity , Rammer rollover and other issues. The ultra-high energy level dynamic compaction and replacement compatible construction technology described in the present invention is suitable for the following original weak soil foundations,

[0041] 1) The backfill layer of the reclamation foundation;

[0042] 2), the loose sediment layer on the seabed;

[0043] 3) The marine alluvial soft soil layer between the seabed sediment layer and the backfill layer.

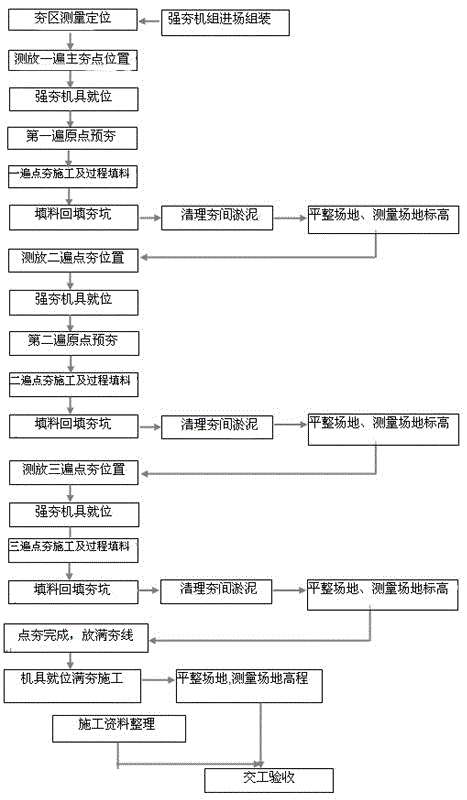

[0044] The specific construction steps are as follows:

[0045] 1) Backfill 1.5-2m thick crushed stone or kaishan stone cushion on the original weak soil foundation, so that the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com