Inner sleeve type concrete-filled steel tube beam column joint and production method thereof

A technology of concrete filled steel pipe and beam-column joints, which is applied in the direction of construction and building construction, and can solve problems such as uncompacted concrete, difficult fabrication, and brittle column walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the drawings and implementation examples.

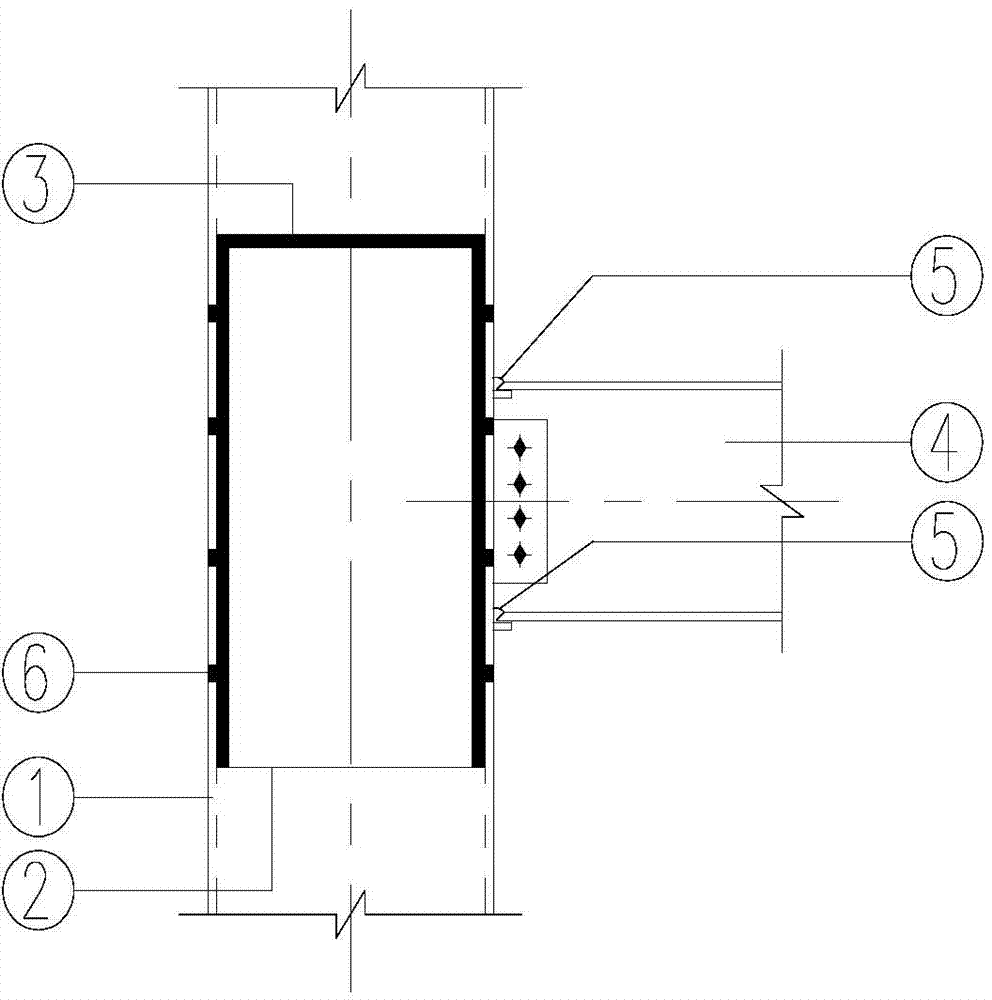

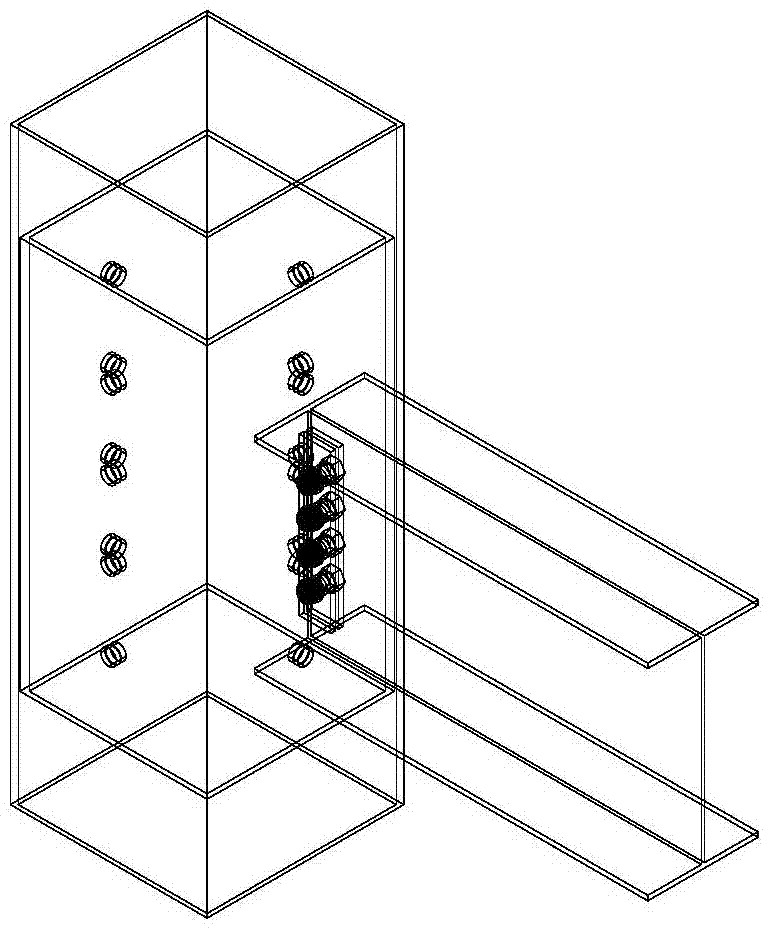

[0015] Such as figure 1 with figure 2 As shown, the inner sleeve type concrete-filled steel tube beam-column node includes a steel tube column 1, an inner sleeve 2 is embedded in the steel tube column, and the gap between the outer wall of the inner sleeve and the inner wall of the steel tube column is 3-4mm, so that the inner sleeve can be plugged smoothly Into the steel pipe column. The inner sleeve and the steel pipe column are welded together along the periphery; the inner sleeve and the steel pipe column are welded together on the upper and lower sides of the steel pipe column and the steel beam 4 flange weld 5 to make the inner sleeve and the steel pipe column Connect as a whole. It is preferable to use plug welding at the weld between the inner sleeve and the steel pipe column.

[0016] The specific manufacturing method is as follows: disconnect the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com