Vertical well drilling automatic adjusting device and adjusting method

An automatic adjustment device and vertical drilling technology, applied in drilling equipment, directional drilling, support devices, etc., can solve the problems of small working pressure on bit range, only light pressure lifting, increased drilling risk, etc., and achieve WOB adjustment. The effect of large range, fast response speed and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

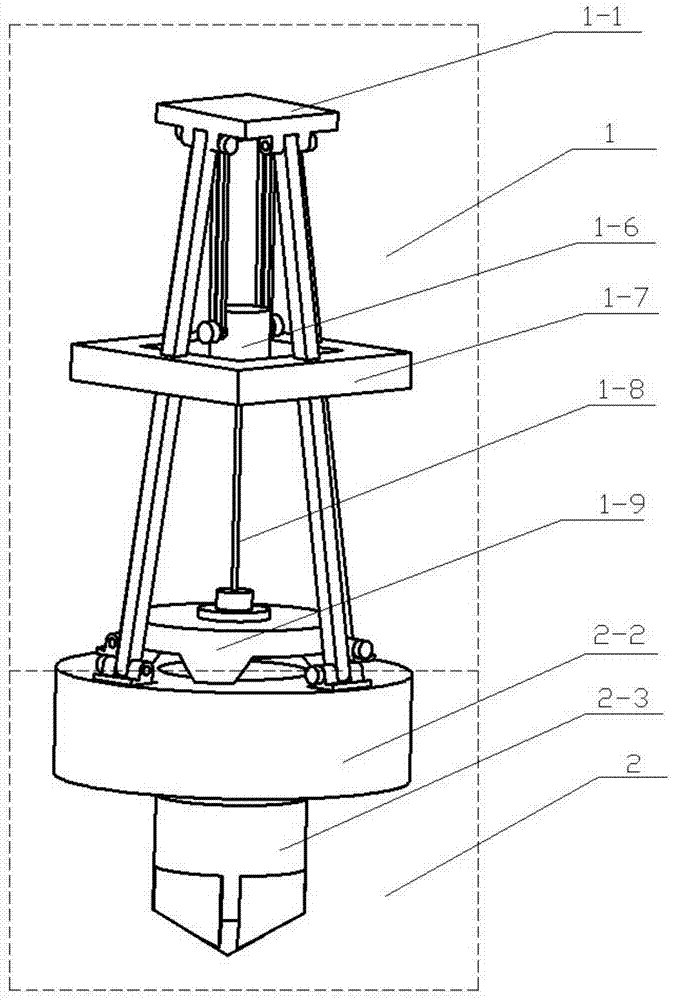

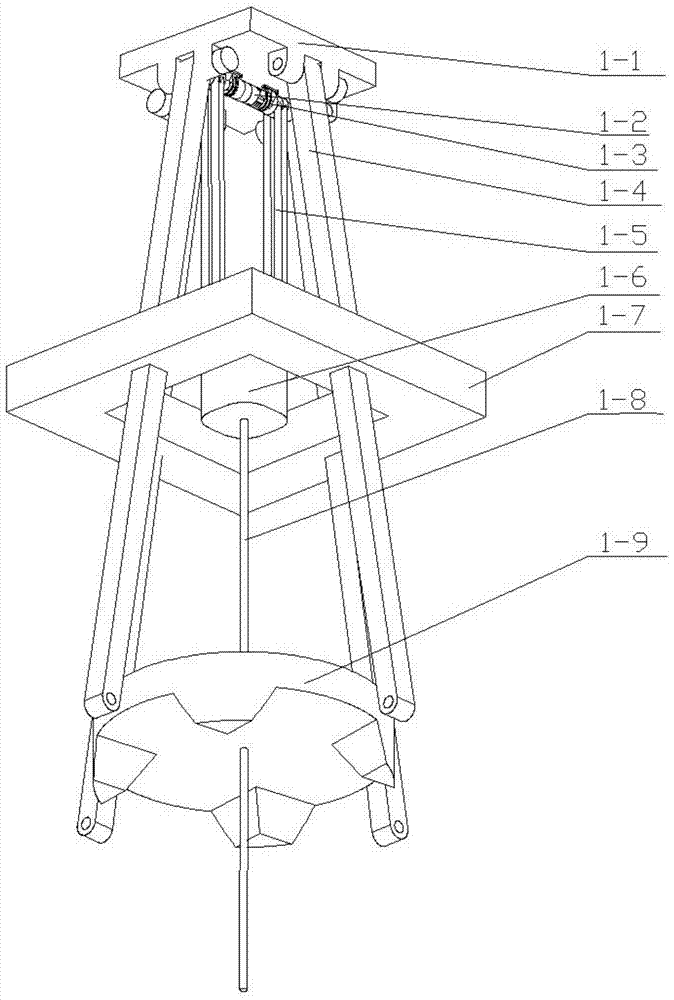

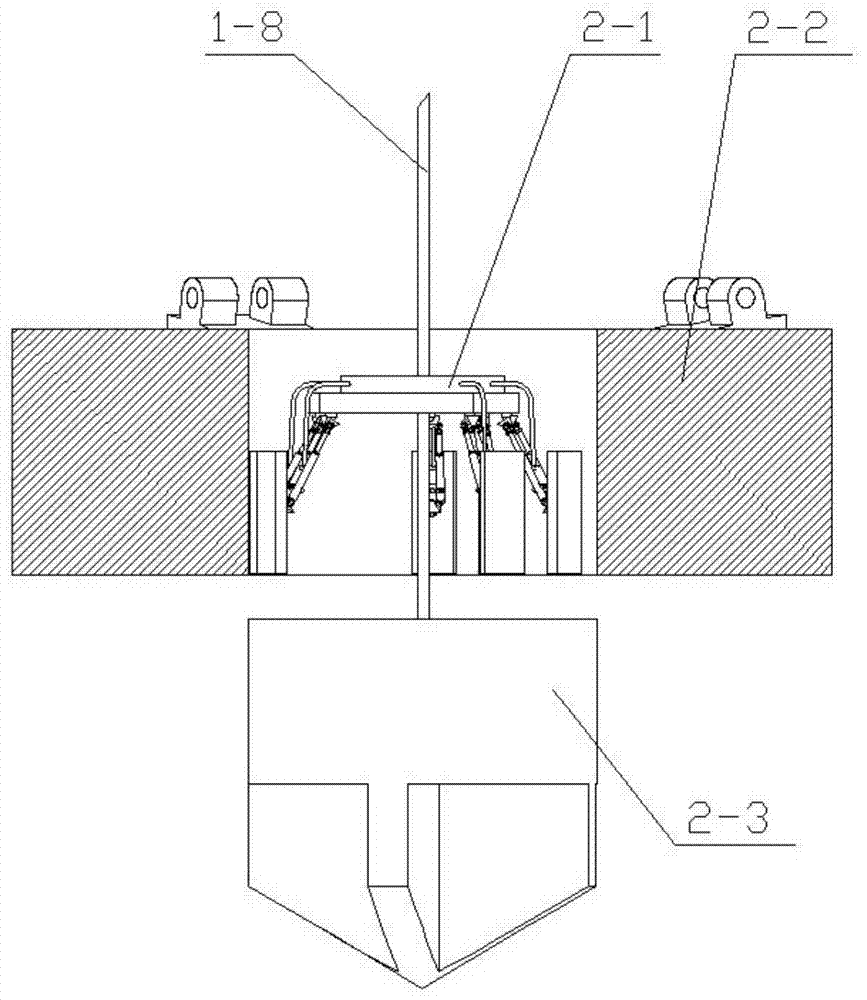

[0028] see figure 1 , figure 2 , image 3 with Figure 4 , the structure of the vertical drilling automatic adjustment device in the present embodiment is set as:

[0029] Such as figure 1 As shown, the vertical drilling automatic adjustment device is divided into an uphole device 1 and a downhole device 2. On the derrick 1-4, a roof 1-1 on the top floor, a second-floor platform 1-7 socketed in the middle of the derrick, and a guide platform are respectively arranged. 1-9 is located on the wellhead and on the center line of the derrick 1-4, and a six-degree-of-freedom parallel adjustment platform 2-1 is set at the height position between the guide platform 1-9 and the downhole drill bit 2-3, so that The six-degree-of-freedom parallel adjustment platform 2-1 is located at a position not exceeding 2000mm higher than the drill bit 2-3; on the roof 1-1, a reducer 1-2 driven by a diesel engine is fixed, and the output of the reducer 1-2 The end is set as a drum 1-3, and a ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com