Drill pipe monitoring method and drill pipe monitoring device

A monitoring device and drill pipe technology, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc. It can solve the problems of large judgment error with rod, false image with rod, and inability to determine the drill pipe, etc., so as to eliminate the problem of with rod Illusion, small judgment error, and the effect of facilitating remedial measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. Various preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

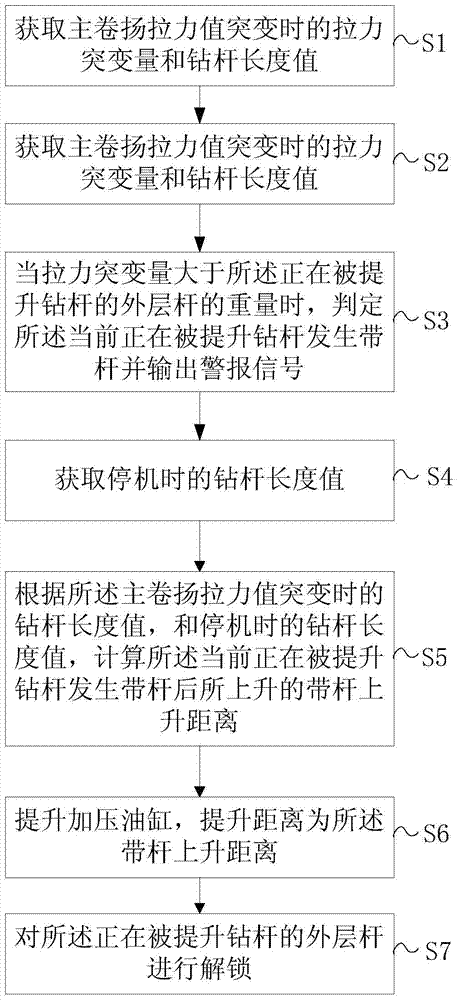

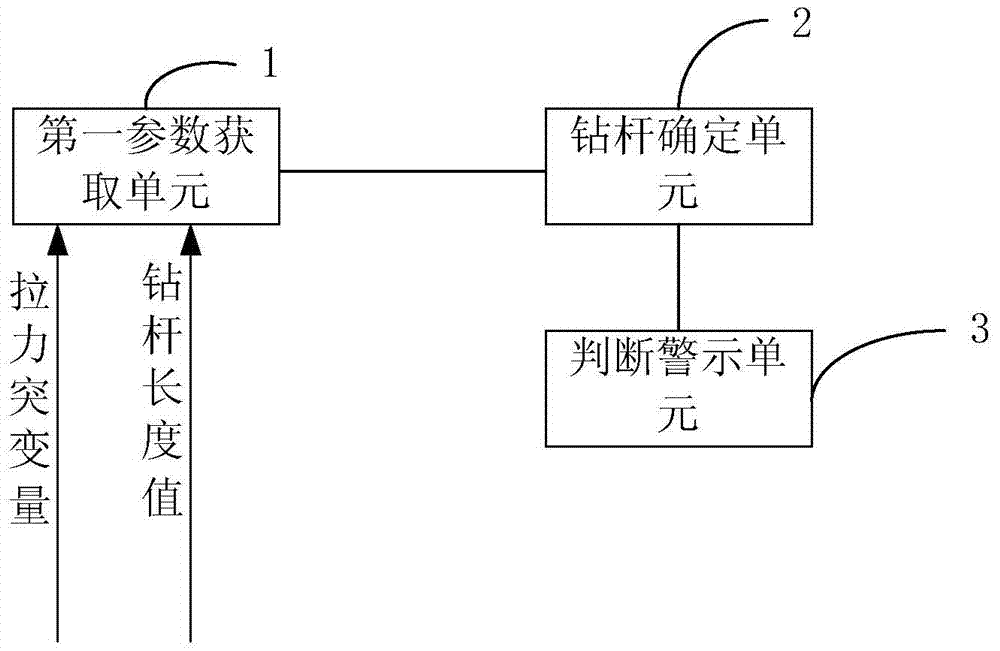

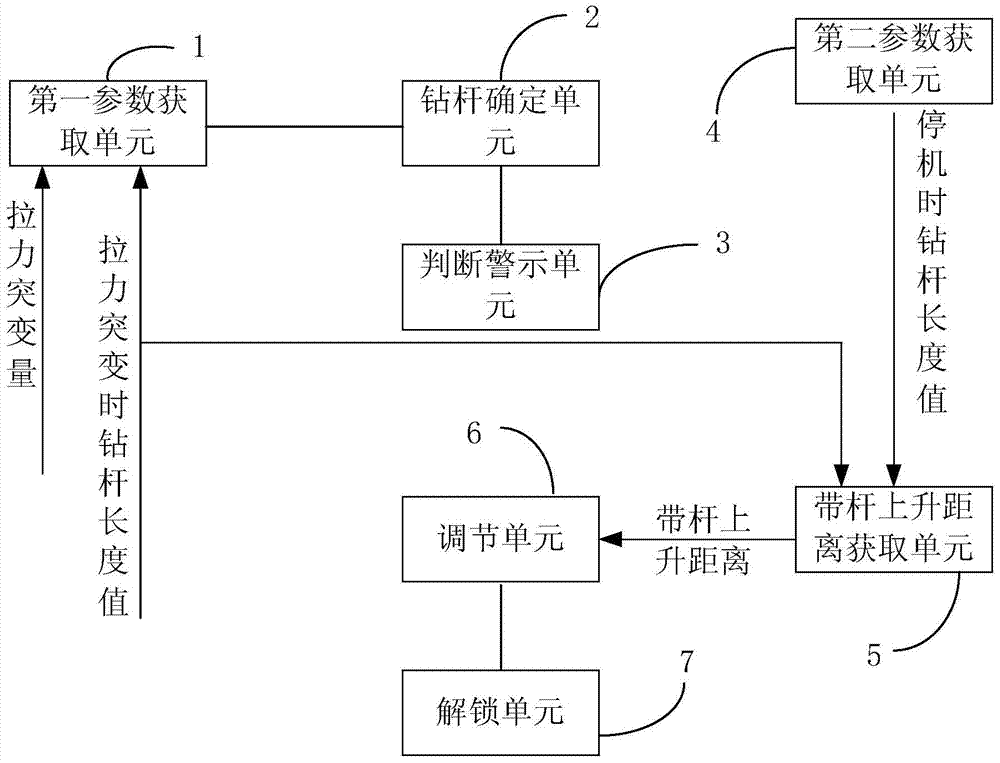

[0051] See figure 1 , Embodiment 1 of the present invention provides a drill pipe monitoring method, comprising the steps of:

[0052] S1. Obtain the sudden change in pulling force and the length of the drill pipe when the pulling force of the main winch changes suddenly;

[0053] S2. Determine the drill pipe currently being lifted according to the drill pipe length value;

[0054] S3. When the sudden change in tension is greater than or equal to the weight of the outer layer of the drill pipe being lifted, it is determined that the drill pipe currently being lifted has a rod and an alarm signal is output.

[0055] It should be noted that the above-mentioned outer layer rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com