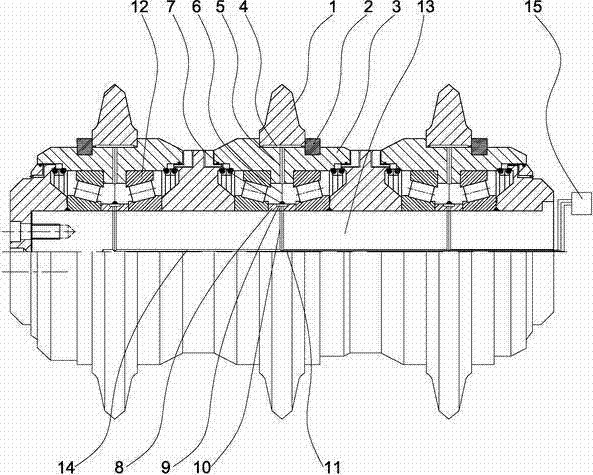

Shield end cover fixed type multi-blade hobbing cutter

A technology of end cover fixing and shield tunneling, which is applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problems affecting the service life of the hob and the pressure of the hob exceeds the limit, so as to improve the service life and reduce the manufacturing cost. Low, easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Such as figure 1 As shown, a shield end cover fixed multi-blade hob of the present invention includes a cutter ring 1, a wedge 2, a cutter body 3, a bearing 12, a bushing 8, and a rotating shaft 13. The cutter ring 1 passes through the wedge 2 is fixed on the outer circle of the cutter body 3, and the said cutter body 3 forms a rotatable connection with the rotating shaft 13 through the bearing 12. Between the inner rings, a pressure sensor 4 is installed on the inner circumferential surface where the cutter ring 1 matches the cutter body 3, and the pressure sensor 4 is connected with a first signal line 6, and the first signal line 6 passes through the cutter The radial through hole 5 processed on the body 3 is connected to the electrode 7, and the area corresponding to the electrode 7 on the outer surface of the bush 8 is inlaid with a circular electrical connector 9, and the electrode 7 is connected to the electrical connector. 9 to form a sliding contact connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com