Center cutter of shield tunneling machine

A center knife and shield machine technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of non-detachable connections, non-replaceable blades, waste of resources, etc., and achieve low manufacturing costs, long service life, and avoid resources. the wasteful effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

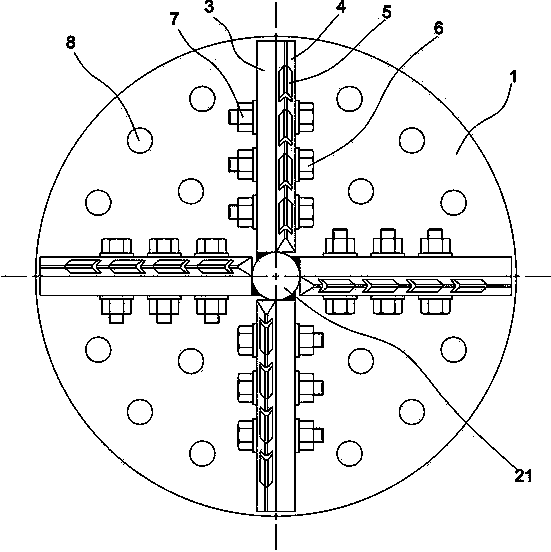

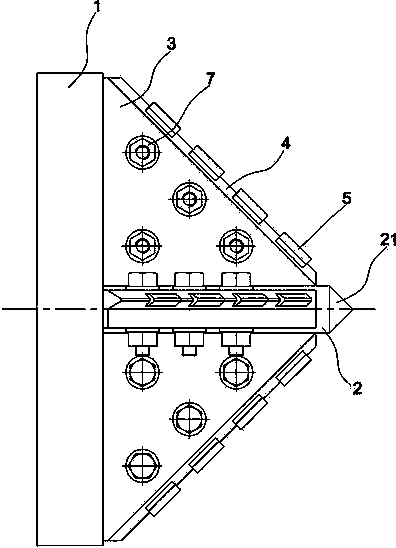

[0012] Such as figure 1 and figure 2 As shown, a center knife of a shield machine of the present invention includes a knife seat 1, a center knife 2, four side knife seats 3, and four side knife seats 4. The knife seat 1 is disc-shaped, and the center knife 2. Welding and fixing on the center of the base 1, the four side knife seats 3 are welded and fixed on the periphery of the center knife 2 according to the center symmetry, and the four side knives 4 are connected by bolts 6, nuts 7) and four side knife seats 3 are fixedly connected together, and the side knife 4 and the side knife seat 3 form four knife arms, and the angle between them is 90 degrees.

[0013] A cemented carbide block is welded on the surface of the conical end 21 of the center knife 2 .

[0014] The height of the hypotenuse of the knife seat 3 is lower than that of the side knife 4 , and the surface of the hypotenuse of the side knife 4 is welded with a cemented carbide block 5 .

[0015] The tool seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com