Connecting Bracket for Automobile Oil Pipe and Its Riveting Process

A technology for connecting brackets and oil pipes, applied in the directions of pipeline brackets, pipes/pipe joints/pipe fittings, pipe components, etc., it can solve the problems such as the inability to guarantee the torsion force and pulling force between the oil pipe joint and the bracket, and achieve simple structure, guaranteed torsion force, Guaranteed effect of pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments

[0028] as attached figure 1 To attach Figure 5 As shown, a riveting process for connecting brackets of automobile oil pipes includes the following steps:

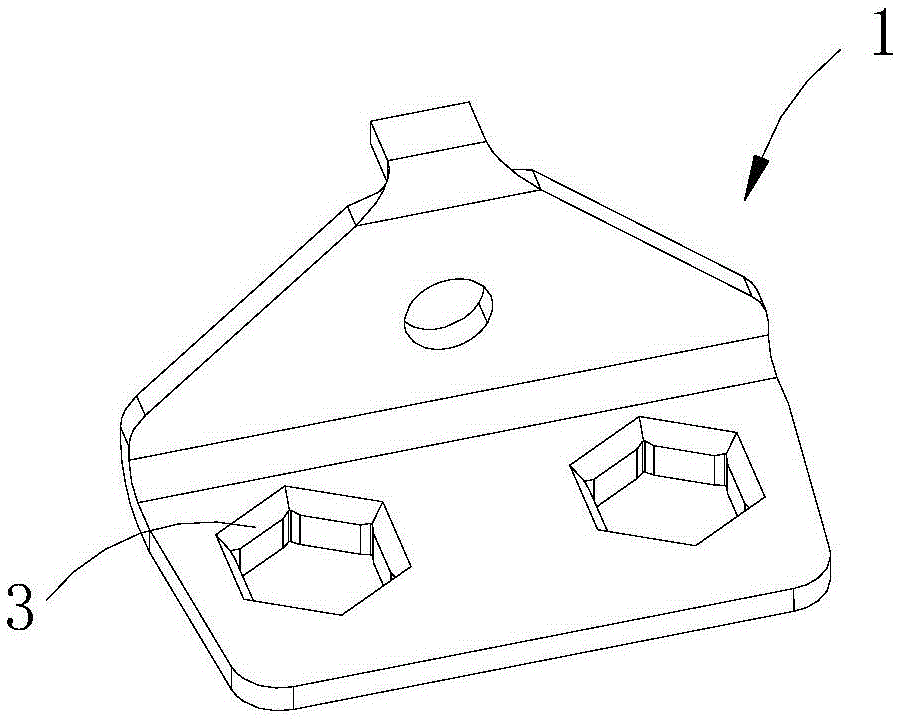

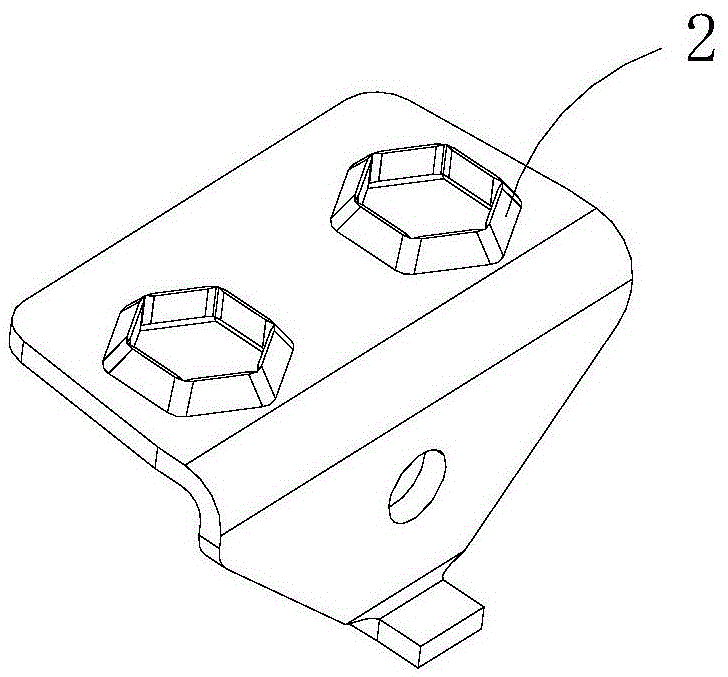

[0029] S1. Take the sheet metal material and carry out cutting, stamping and bending forming to form the required bracket 1; as a preference, two holes are symmetrically arranged on the bracket wall of the bracket 1 of the present invention, and the other side wall of the bracket is connected to the bracket. The wall is vertical, and is provided with installation holes and positioning hooks, so as to facilitate the installation and positioning of the bracket.

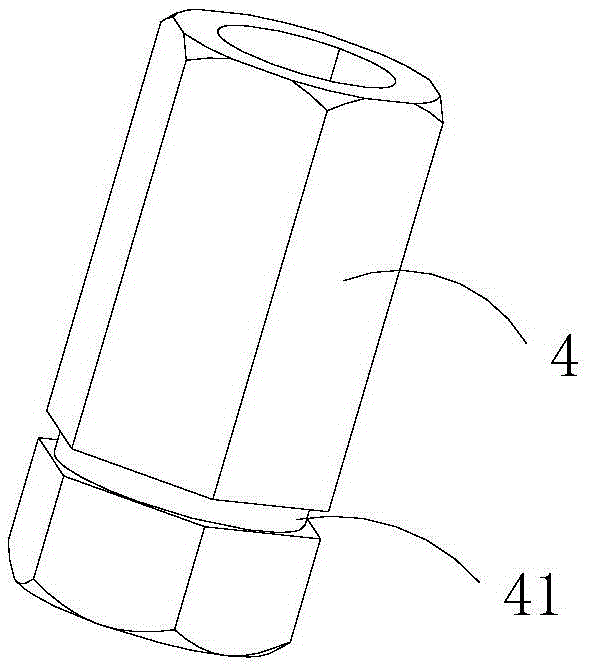

[0030] S2. Pull the convex bump 2 at the hole position of the bracket wall of the bracket 1; in this way, it is convenient to squeeze the convex bump into the annular holding groove 41, thereby incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com