Toy oven

A technology for ovens and toys, applied in drying, dryers, progressive dryers, etc., can solve problems such as high local stability and impact on children's health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

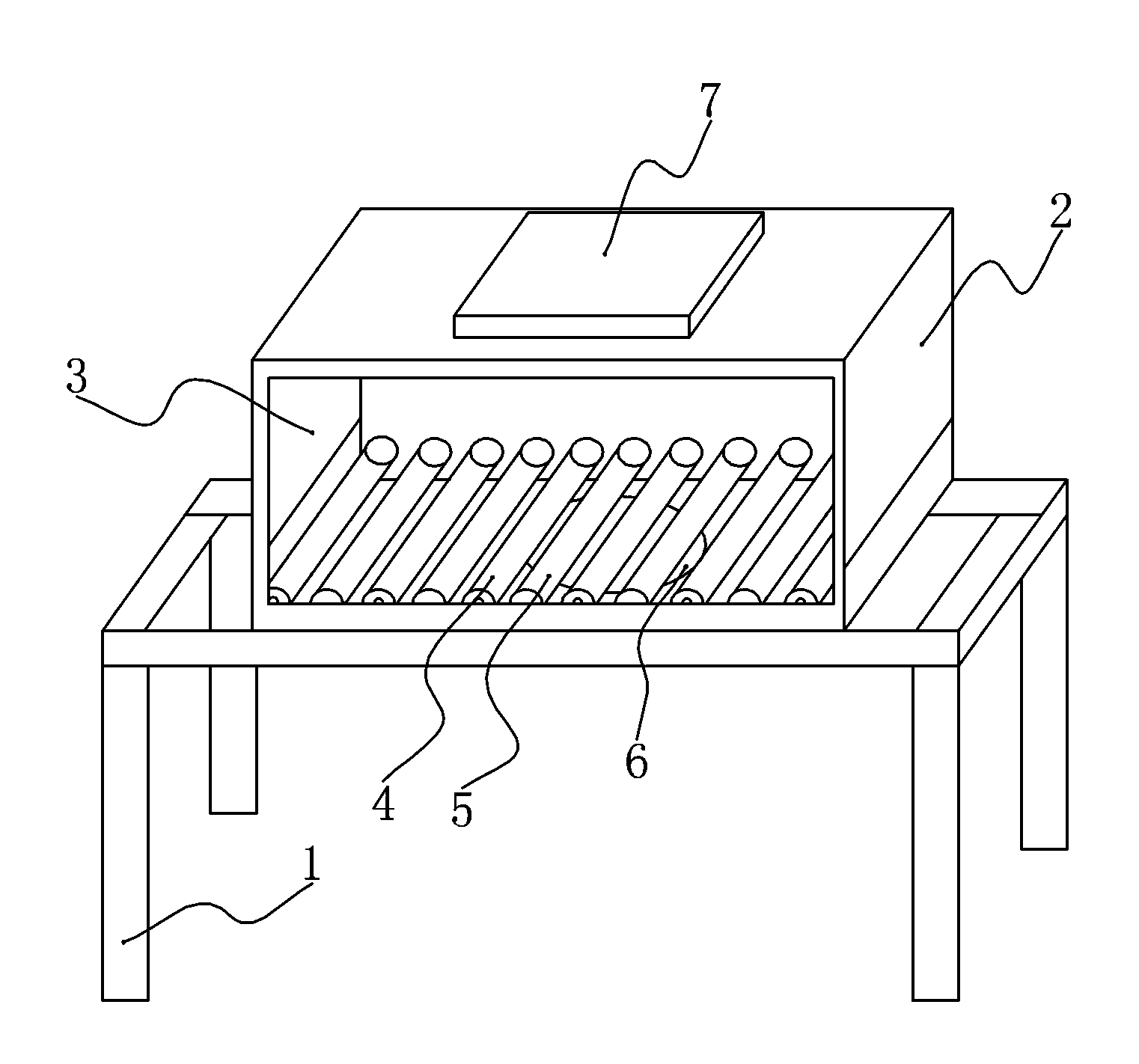

[0010] Such as figure 1 As shown, the toy oven of the present invention includes a frame 1, on which an oven 2 is fixed, and one side of the oven 2 is provided with a transparent observation window 3, which can be made of glass. It can be seen through the observation window that a horizontal transmission roller 4 is arranged at the lower position of the oven 2, and the transmission roller 4 can be driven by a motor to transmit the objects placed thereon. Obviously, in order to realize the transmission, the diameter of the driving roller 4 needs to match the size of the object according to the actual situation. In addition, in the gaps between the driving rollers 4, heating pipes 5 are alternately arranged, and the heating pipes 5 can be electric heating pipes, and the heating temperature is preset within a reasonable range. An oval air inlet 6 is opened at the bottom of the oven 2, and an air pump is fixed on the frame 1 to blow air into the air inlet 6, which can disperse th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com