Flow feature test equipment for fire extinguishing system pipe network

A technology of fire extinguishing system and experimental equipment, which is applied in the field of experimental equipment for the flow characteristics of the fire extinguishing system pipe network, can solve the problems of lack of flow characteristics of the fire extinguishing system pipe network, and achieve the effect of accurate description

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below through implementation examples in conjunction with the accompanying drawings, but the implementation scope of the present invention is not limited to this arrangement.

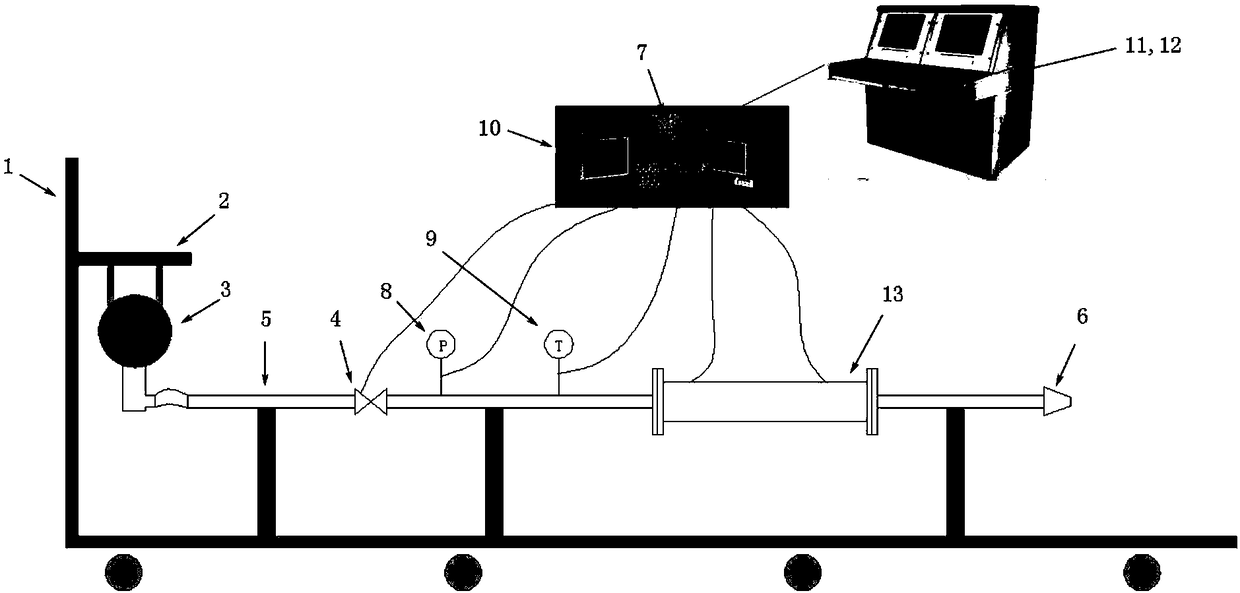

[0024] Such as figure 1 As shown, a kind of fire extinguishing system pipe network flow characteristics experimental equipment of the present invention includes an experimental bench 1, a fire extinguisher hanger 2, a fire extinguisher 3, a solenoid valve 4, a delivery pipeline 5, a terminal nozzle 6, a test interface 7, Pressure sensor 8, temperature sensor 9, signal conditioning and data acquisition module 10, industrial computer 11, console 12, and flow field visualization tomography analysis unit 13, the above-mentioned parts are connected to form a unit through mechanical connections, electrical cables and transportation pipelines Laboratory equipment.

[0025] figure 1 A schematic structural diagram of an experimental equipment for the flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com