Device for measuring shredding width accurately and using method thereof

A technology of shredding and width, applied in the direction of measuring devices, instruments, etc., can solve the problems of large measurement errors, monitoring, irregular shapes, etc., and achieve the effect of reliable measuring devices and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

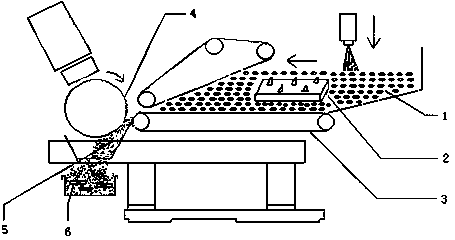

Method used

Image

Examples

experiment example 1

[0036] According to the device recorded in the present invention, the shredded width of A brand cigarette is tested, the shredding machine model is Garbuio SD5, and the shredded width design value is 0.9mm.

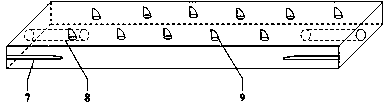

[0037] The paraffin body used in the test is 15cm long, 3.0cm wide, and 1.0cm high. The upper and lower convex teeth of the paraffin body are 0.5cm high, and the color of the paraffin body is dark green. The test steps are:

[0038] a. Before the test, use a puncher to punch blind holes at both ends of the paraffin body, with a depth of 2.5cm, and the position of the blind holes is in the middle of the two ends;

[0039] b. During the production process, put the paraffin body into the tobacco leaves of the feeding device of the shredder, put it into the depth of 20cm, and place it in the middle of the feeding device of the shredder;

[0040] c. After shredding, pick out the paraffin body sheet from the leaf shreds, pick out the paraffin body sheet with holes, and measure...

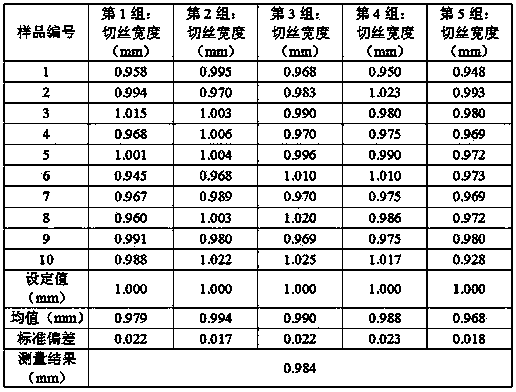

experiment example 2

[0044] The device described in Experimental Example 1 was used to test the shred width of brand B cigarettes. The shredding machine model was Garbuio SD5, and the shred width setting value was 1.0 mm. The test results are as follows:

[0045]

experiment example 3

[0046] Experimental Example 3: Using the device described in Experimental Example 1, the cut-stem width of the cut stems used in B brand cigarettes was tested. The model of the cut-stem machine was KT2-S160, and the set value of the cut-stem width was 0.20mm. The test results are as follows:

[0047]

[0048] Experimental Example 1 and Experimental Example 2 of the present invention are the measurement results of the width of the shredded leaves, and Experimental Example 3 is the measurement result of the width of the shredded stems. Experimental Example 1 and Experimental Example 2 have the same model of shredding machines, but the difference lies in that the grades of the test cigarettes are inconsistent and the designed shredding widths are inconsistent. Experimental example 3 is inconsistent with experimental example 1 and experimental example 2. The test devices, methods and principles of the three are the same. It can be seen from the measurement results that the meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com