Battery Sorting Method Based on Working Condition Test and Simplified Impedance Spectroscopy Equivalent Circuit Model

A technology of equivalent circuit model and impedance spectrum, which is applied in the direction of measuring electricity, measuring electrical variables, sorting, etc., can solve problems such as low reliability, slow battery sorting speed, and few sorting parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

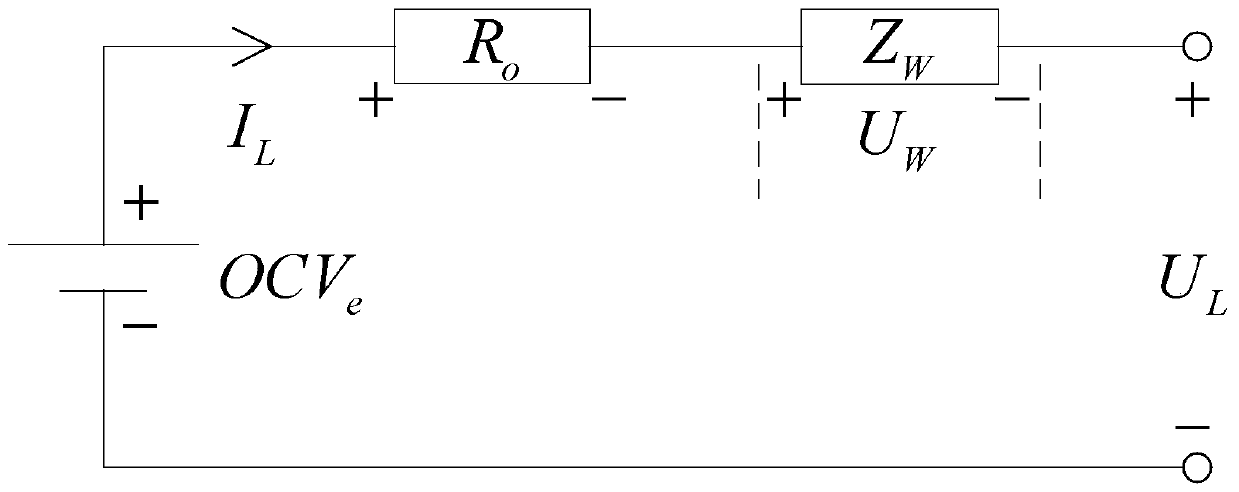

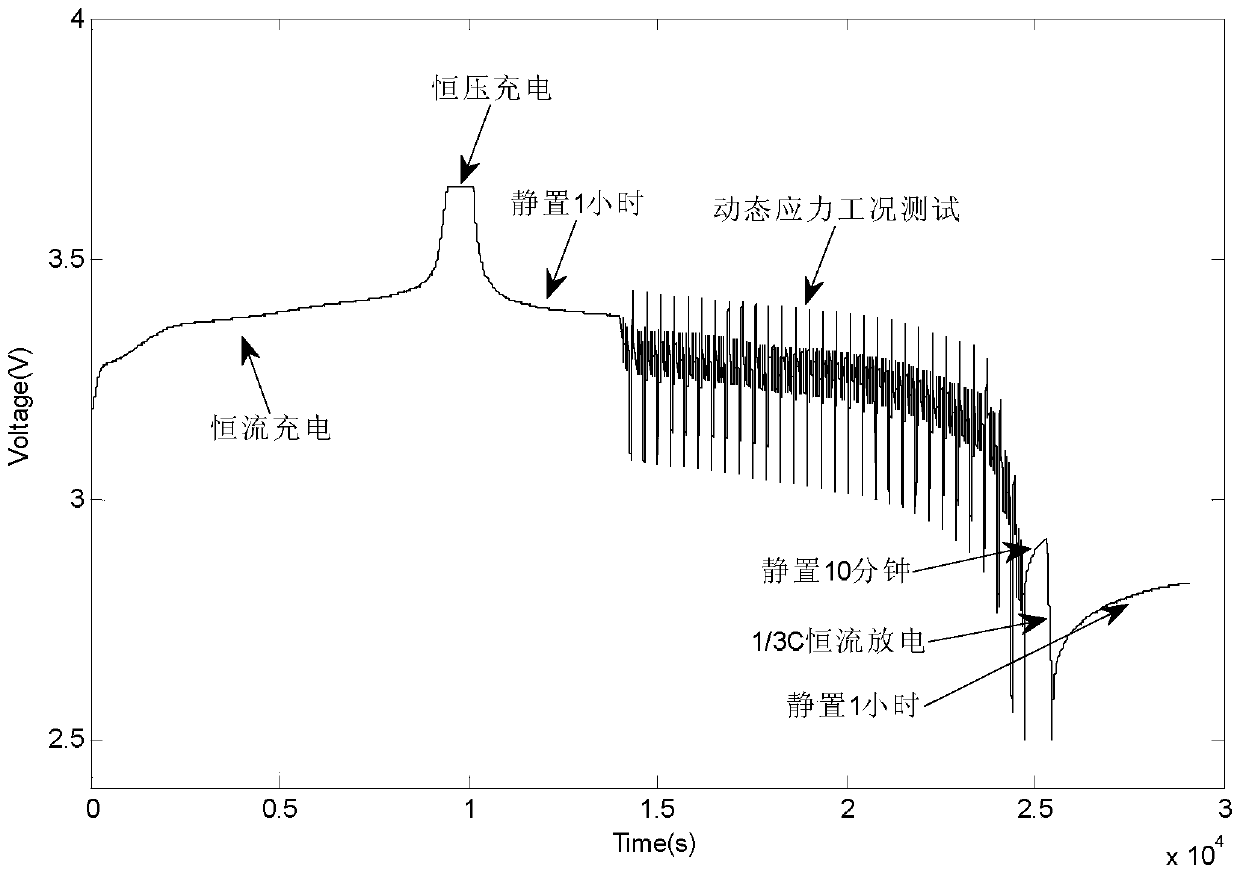

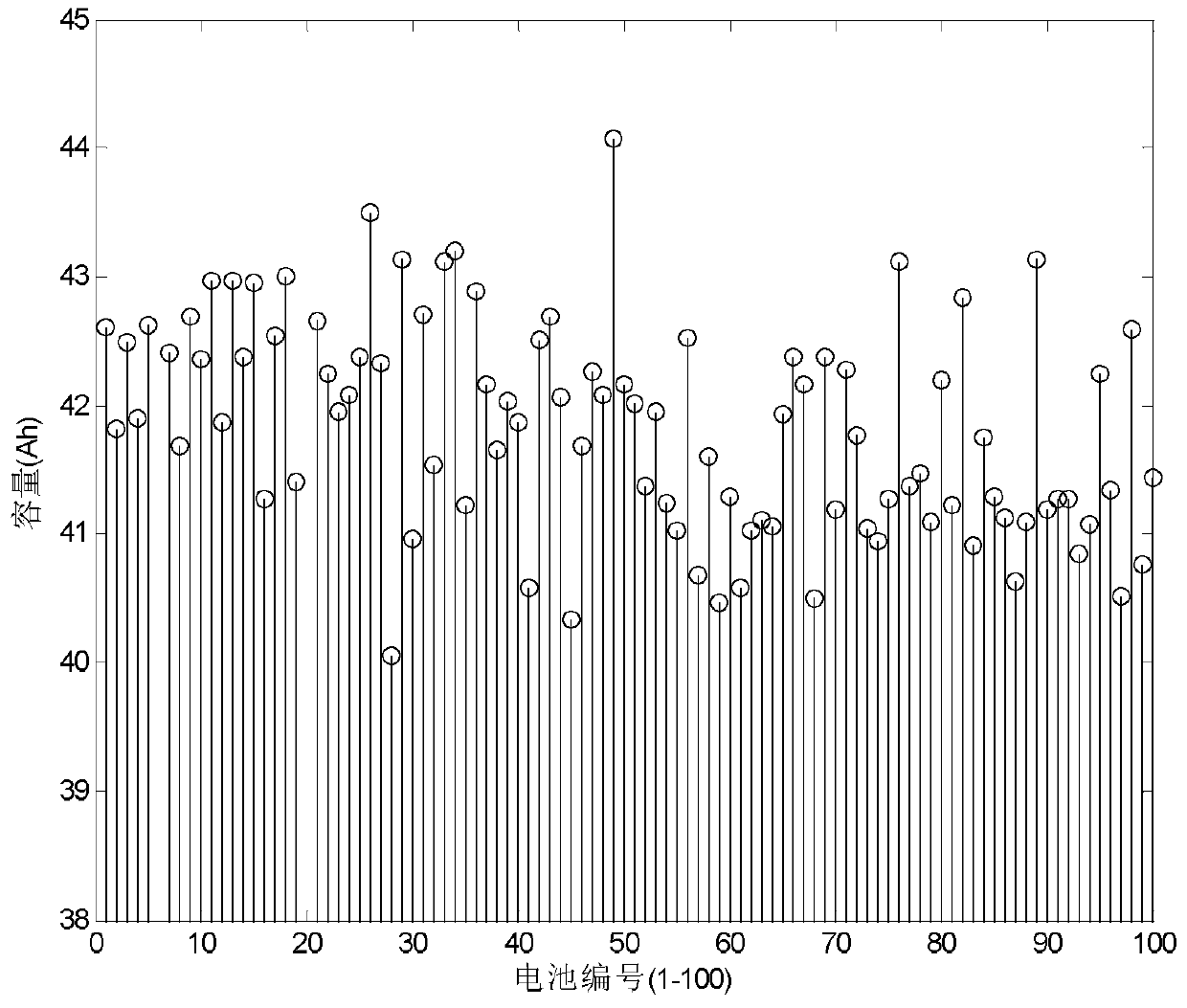

[0110] Specific implementation mode 1. Combination figure 1 To illustrate the specific implementation mode, the present invention discloses a dynamic sorting method for power batteries, including steps: A) simultaneously charge or discharge multiple batteries to be sorted; B) detect in real time whether multiple batteries are charging or discharging The voltage value at the start time and the voltage value at the end time of a specific time period before the end of the discharge operation, so as to obtain the difference between the voltage value at the start time and the voltage value at the end time of multiple batteries in a specific time period before the end of the charging or discharging operation ; C) Using the difference between the voltage value at the start moment and the voltage value at the end moment of the battery at a specific time period before the end of the charging or discharging operation as a standard, sorting and matching multiple batteries to form multiple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com