Small stabilized platform friction torque testing method based on force balance

A stable platform and friction torque technology, applied in the field of photoelectric detection, can solve problems such as inertial moment measurement interference, uneven speed, etc., and achieve the effects of improving accuracy, enhancing anti-interference ability, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

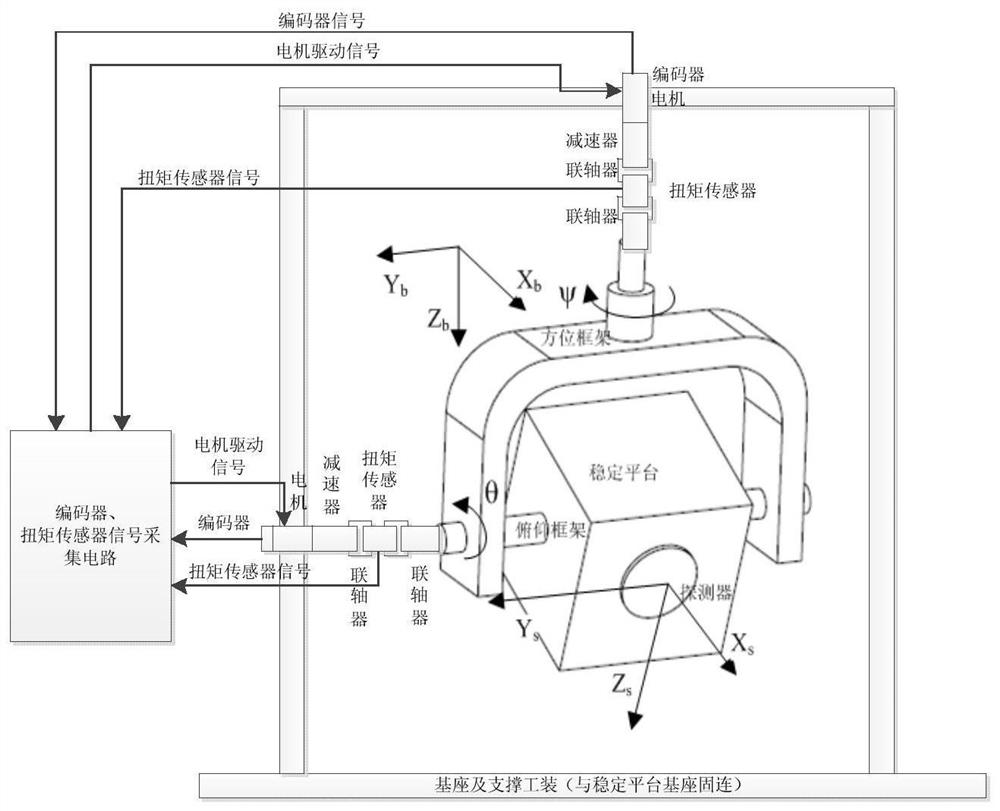

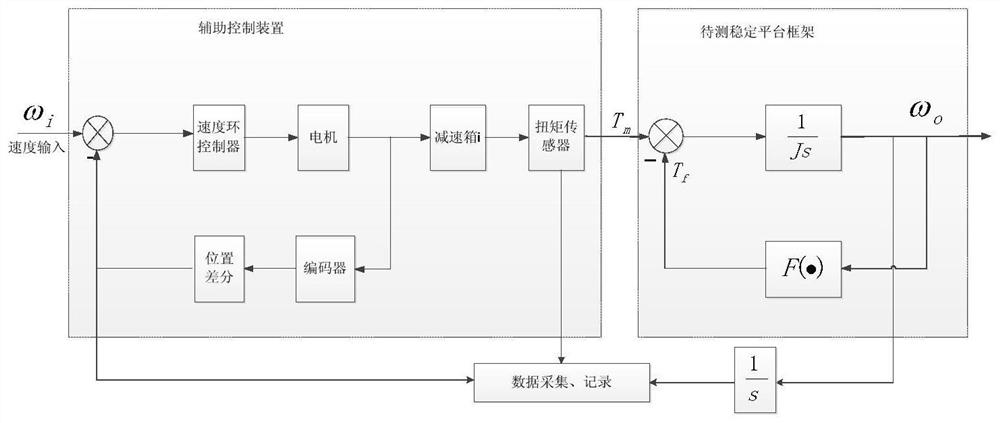

[0025] A small stable platform friction torque test method based on force balance, by adding a control device consisting of a motor, encoder, reduction box, and torque sensor to the stable platform frame to provide accurate and uniform angular rotation, the torque sensor is connected to the platform through a coupling The frame and the reduction box drive the frame to rotate at a constant speed, and the torque transmitted by the torque sensor and the friction torque of the stable platform frame maintain a torque balance. By collecting information from encoders, torque sensors, and angle sensors, the friction torque at different speeds and different positions can be obtained, so as to evaluate the consistency of optical-mechanical assembly and adjustment, and compensate in the stability control algorithm to enhance the anti-interference ability of the photoelectric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com