Anti-tensile optical fiber contact and optical fiber connector provided with same

A technology for optical fiber connectors and optical fiber contacts, which is applied in the coupling of optical components, optical waveguides, light guides, etc., can solve the problems of locking parts that are easy to fall off, and achieve the effects of reliable connection, convenient use, and loss prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

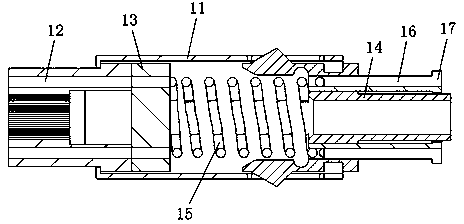

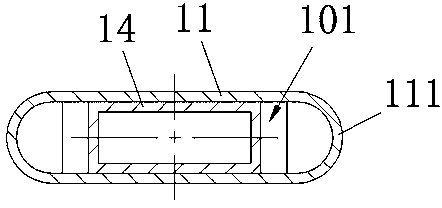

[0024] Examples of pull-out resistant fiber optic contacts, such as Figure 1-6 As shown, the anti-pulling optical fiber contact includes a housing 11 , an MT ferrule 12 , a positioning seat 13 and a locking mechanism, wherein the locking mechanism includes a locking member 14 , a spring 15 and a push rod component.

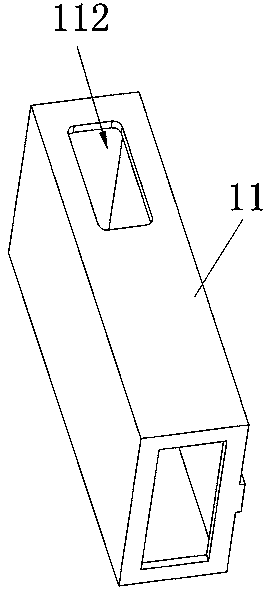

[0025] The casing 11 is a rectangular casing. In this embodiment, the front end of the casing 11 is provided with an inturned edge, and the outer peripheral surface of the MT pin 12 is provided with an inturned edge facing forward to stop the front end of the casing 11. Compatible step surfaces. The MT pin 12, the positioning seat 13, the spring 15 and the locking piece 14 are sequentially loaded into the housing 11 from the rear end of the housing 11, and the ejector part is inserted on the locking piece 14, wherein the locking piece 14 is connected with the locking piece 14. The housings 11 are fixedly assembled together. In this embodiment, both the housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com