Combined type dot matrix image mark and manufacturing method thereof

A technology of a dot matrix image and a manufacturing method, which is applied in the field of anti-counterfeiting signs, can solve the problems of waste of resources, damage to the dot matrix image, and the dot matrix image logo does not have a protective layer of the mark, and achieves the effect of overcoming a single style.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

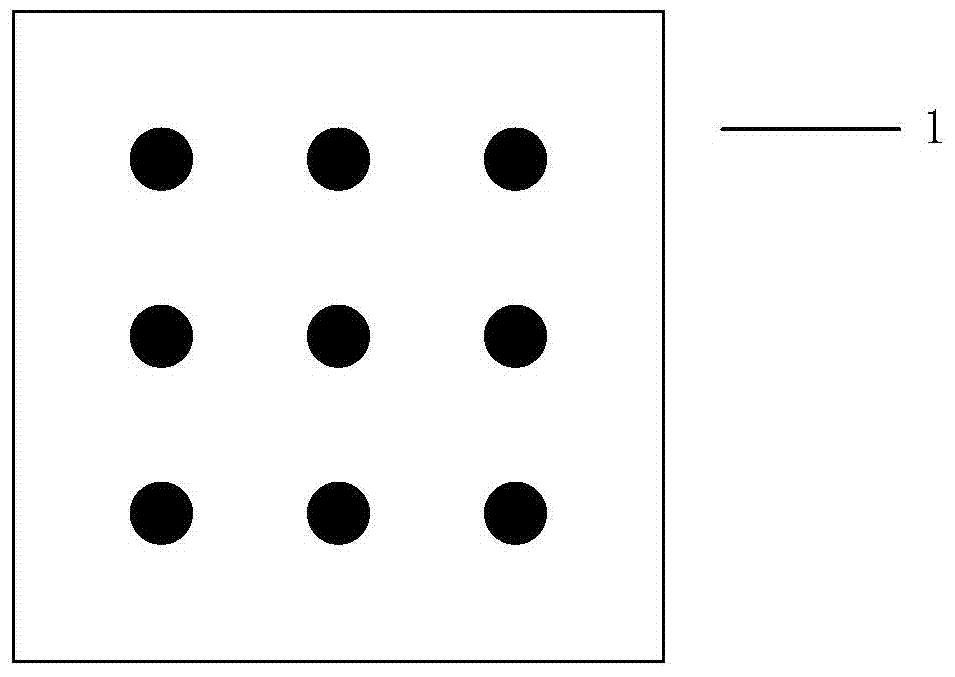

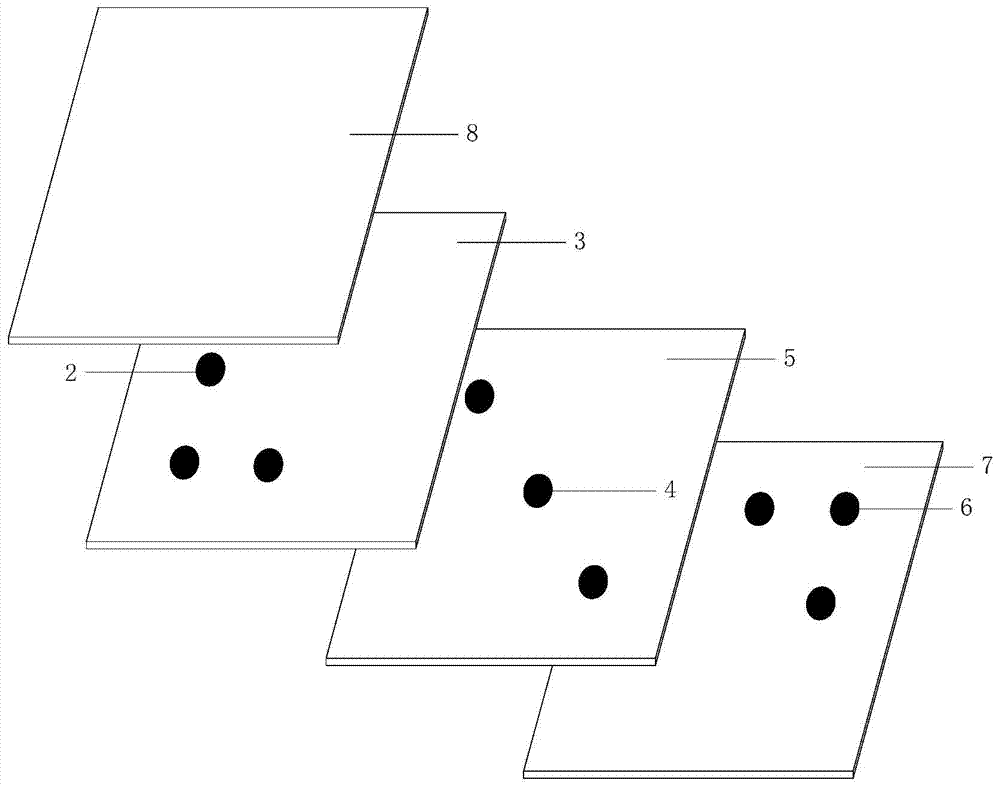

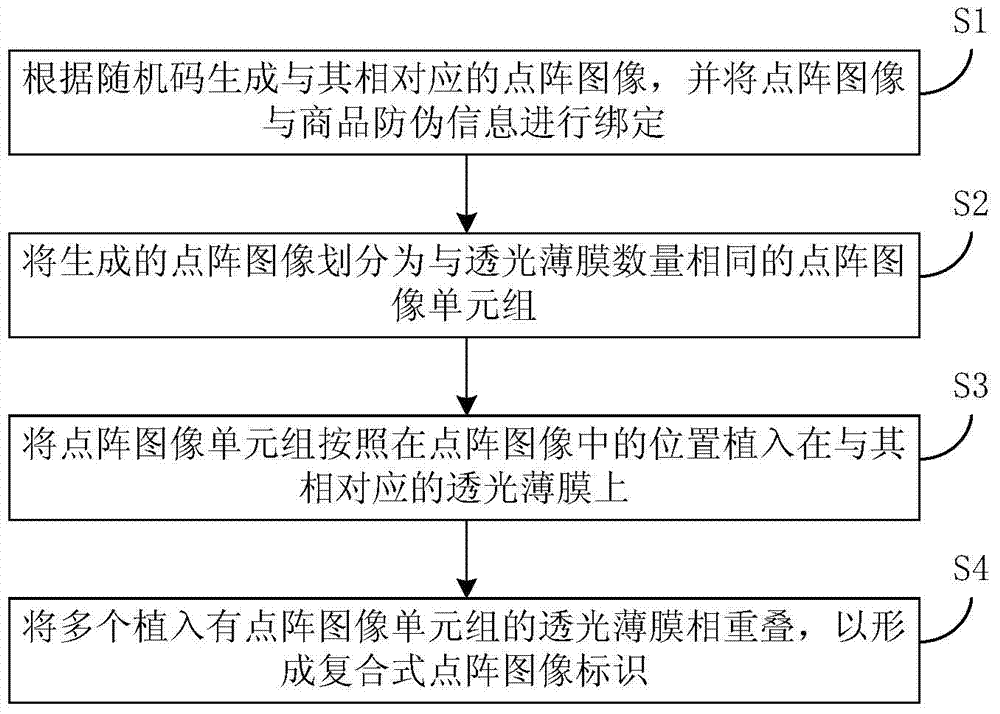

[0027] like Figure 1 to Figure 2 As shown, in this embodiment, the composite dot matrix image sign 1 consists of three layers of light-transmitting films implanted in dot-matrix image unit groups that are sequentially overlapped to form a sign body and a protective light-transmitting film 8 covering its top surface. constitute. The protective light-transmitting film is a plastic light-transmitting film, and the thickness of the plastic light-transmitting film is a hard film of 3000nm to 0.25mm. The logo body is respectively the first layer of light-transmitting film 3 implanted with the first dot matrix image unit group 2, the second layer of light-transmitting film 5 implanted with the second dot matrix image unit group 4, and the third layer of light-transmitting film 5 implanted with the third point The third layer of light-transmitting film 7 of the image unit group 6. The first layer of light-transmitting film and the second layer of light-transmitting film are superim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com