A method of auxiliary trolley for overhead busbar hoisting

A busbar and hoisting technology, applied in the direction of overhead line/cable equipment, transportation and packaging, load hanging components, etc., can solve the problems of reducing construction efficiency, increasing safety hazards, and traction rope wear, so as to save hooking time and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

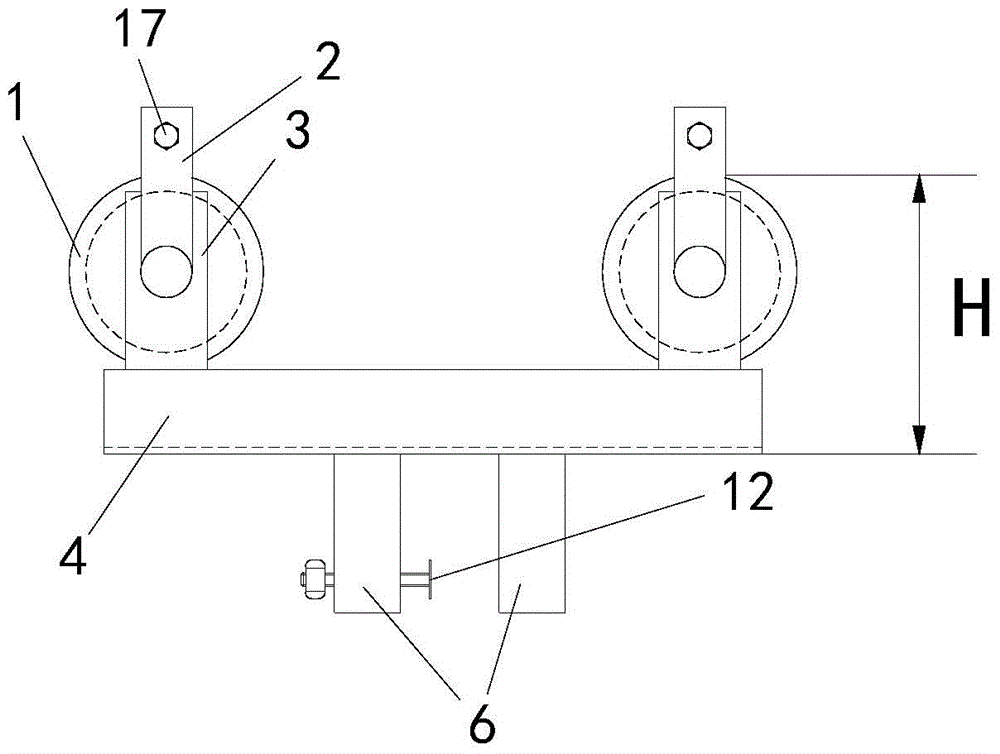

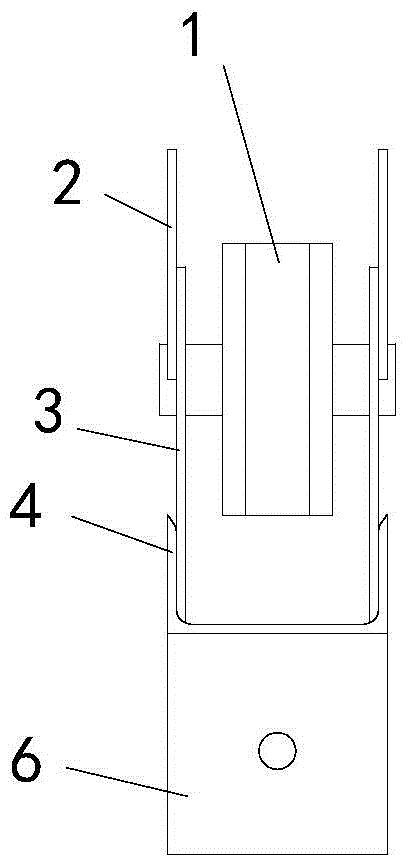

[0038] Such as Figures 2 to 5 As shown, the auxiliary trolley for the hoisting of the overhead soft busbar of the present invention includes a base 4, two pulleys 1, a support arm 3 for fixing each pulley 1, a limit plate 2 and a clamping arm 6 fixed at the lower end of the base 4 , wherein, base 4 is made up of base plate one and is connected with two side walls, and side wall and support arm 3 are flat iron (also can be channel steel or angle steel). The support arm 3 of the present invention is arranged on the upper end of the base 4, each pulley 1 is installed between two support arms 3, the limit plate 2 is connected with the outside of the support arm 3, and the joint is located on the same horizontal line as the central axis of the pulley 1 , and located on both sides of each pulley 1, the top of the limit plate 2 is higher than the top of the round wheel circumference of the pulley 1. The connecting line of the clamping arm 6 of the present invention is parallel to t...

Embodiment 2

[0045] This embodiment differs from Embodiment 1 only in that: Figures 6 to 9As shown, the present invention also includes a balance device 15 for preventing the base 4 from turning over, the balance device 15 is arranged on both sides of the base 4, and includes the second base plate and the triangular plate arranged on the second base plate, and the second base plate and the triangular plate Both are connected with base 4. The base 4 of this embodiment is composed of a bottom plate and a connection with two side walls, and the side walls and the support arm 3 are channel steel.

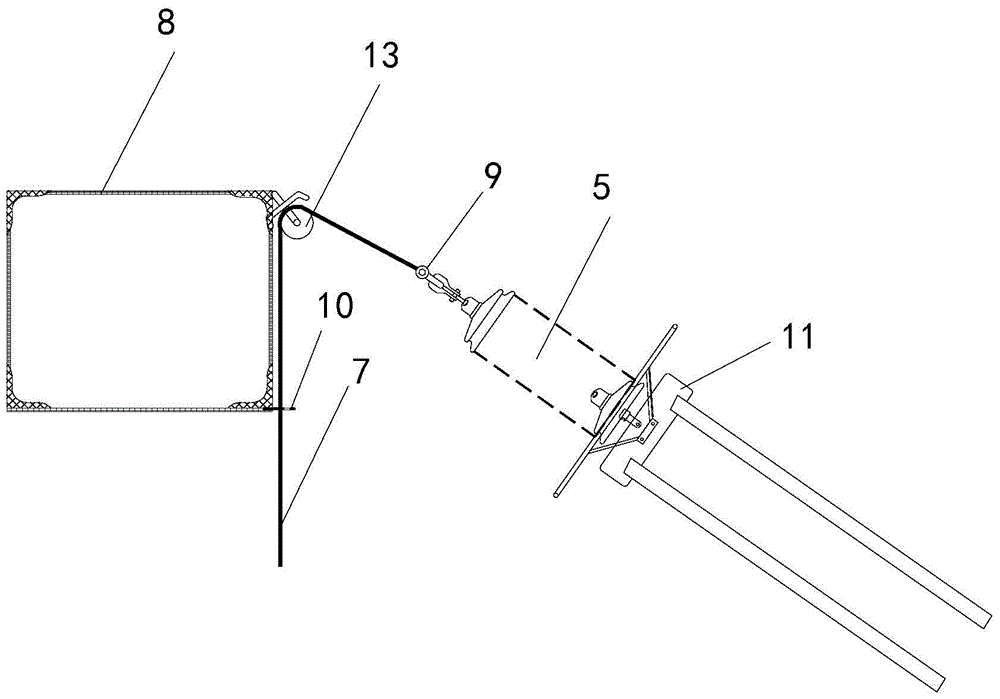

[0046] Hardware hitch rings, traction ropes and soft busbar components such as Figure 4 As shown, the auxiliary trolley for the hoisting of the overhead soft busbar in this embodiment can be applied to the intersection of the crossbeam 8 and two angled steels 16 in the frame: the clamping arm 6 is cross-carded at the intersection of the crossbeam 8 and the two angled steels 16 On the crossbeam 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com