Rheostat structure of electrical-hydraulic rheostat starter

A starter and electro-hydraulic technology, which is applied in the direction of liquid resistors, starter parts, etc., can solve the problems of large waste of electric energy and low efficiency of high current, and achieve the effects of extended maintenance cycle, reasonable structure, simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will now be further explained in conjunction with the drawings:

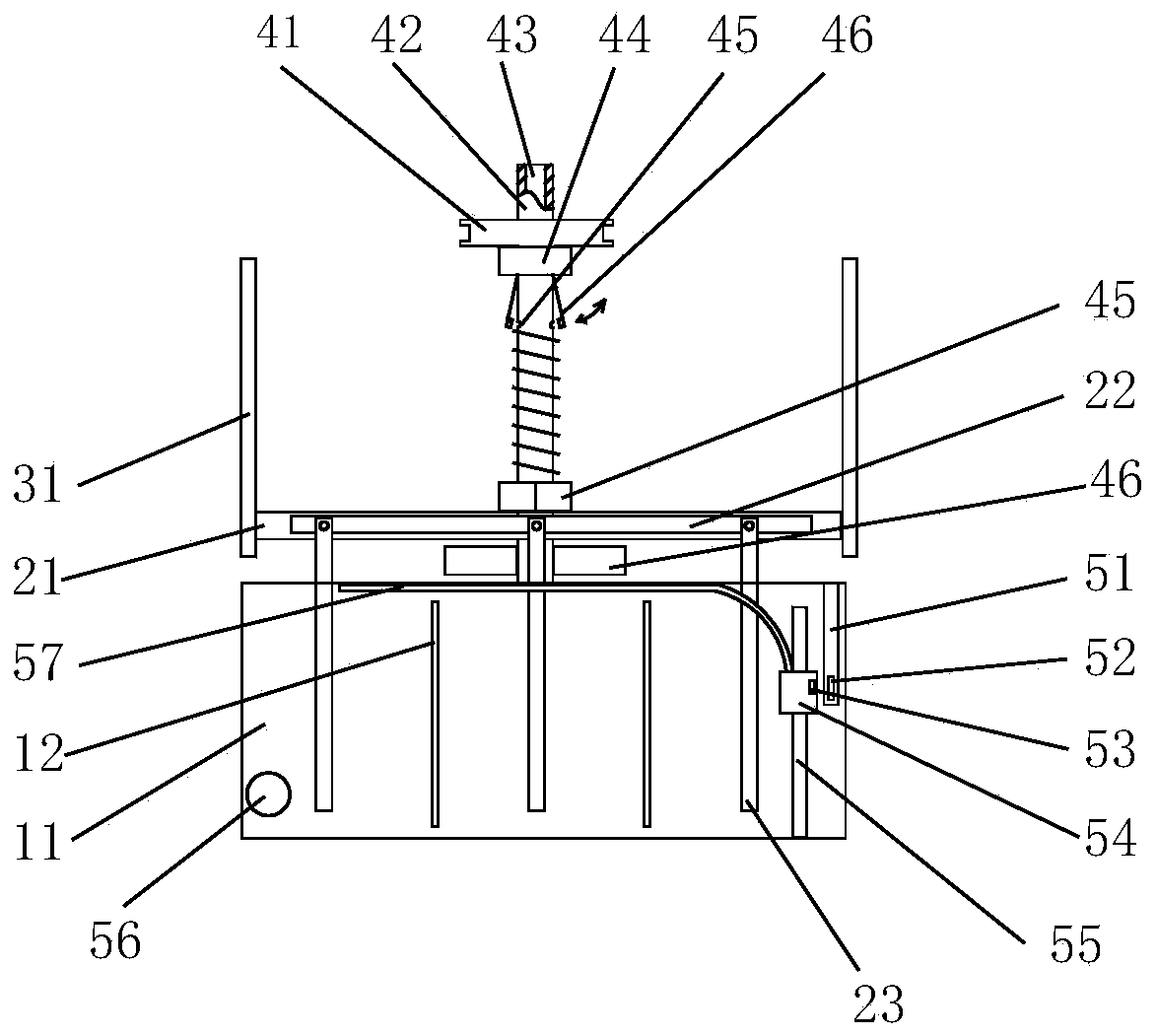

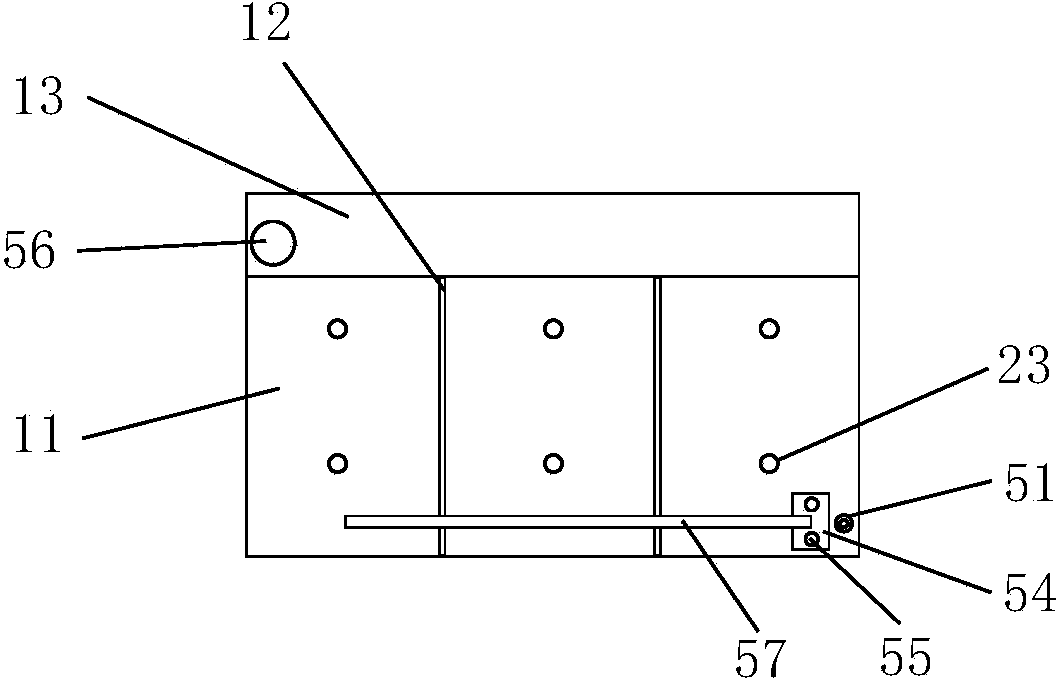

[0041] As shown in the figure, the water tank 11 serves as a water resistance;

[0042] Three pairs of electrode rods 23, connected to water resistance, can output three resistance values;

[0043] The electrode rod lifting structure can simultaneously control the movement of one of each pair of electrode rods 23, thereby changing the water resistance;

[0044] Also includes:

[0045] There are two positioning posts 55, which are fixed in the water tank 11;

[0046] The buoy 54 is sleeved on the positioning column 55 and can move up and down with the water level;

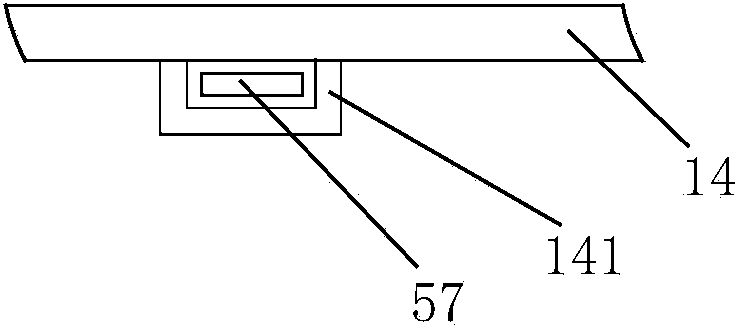

[0047] The flexible indicator strip 57 is partially inserted into the slot 141 on the inner surface of the water tank cover 14 and one end is fixed to the buoy 54. As the buoy 54 moves up and down, the flexible indicator strip 57 can convert the vertical change of the water level into a horizontal change.

[0048] The water tank cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com