Camera module

A camera module and lens technology, which is applied in the electronic field, can solve the problems of unfavorable wide application of camera modules and high cost of camera modules, and achieve the effects of being beneficial to wide application, low cost and high definition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

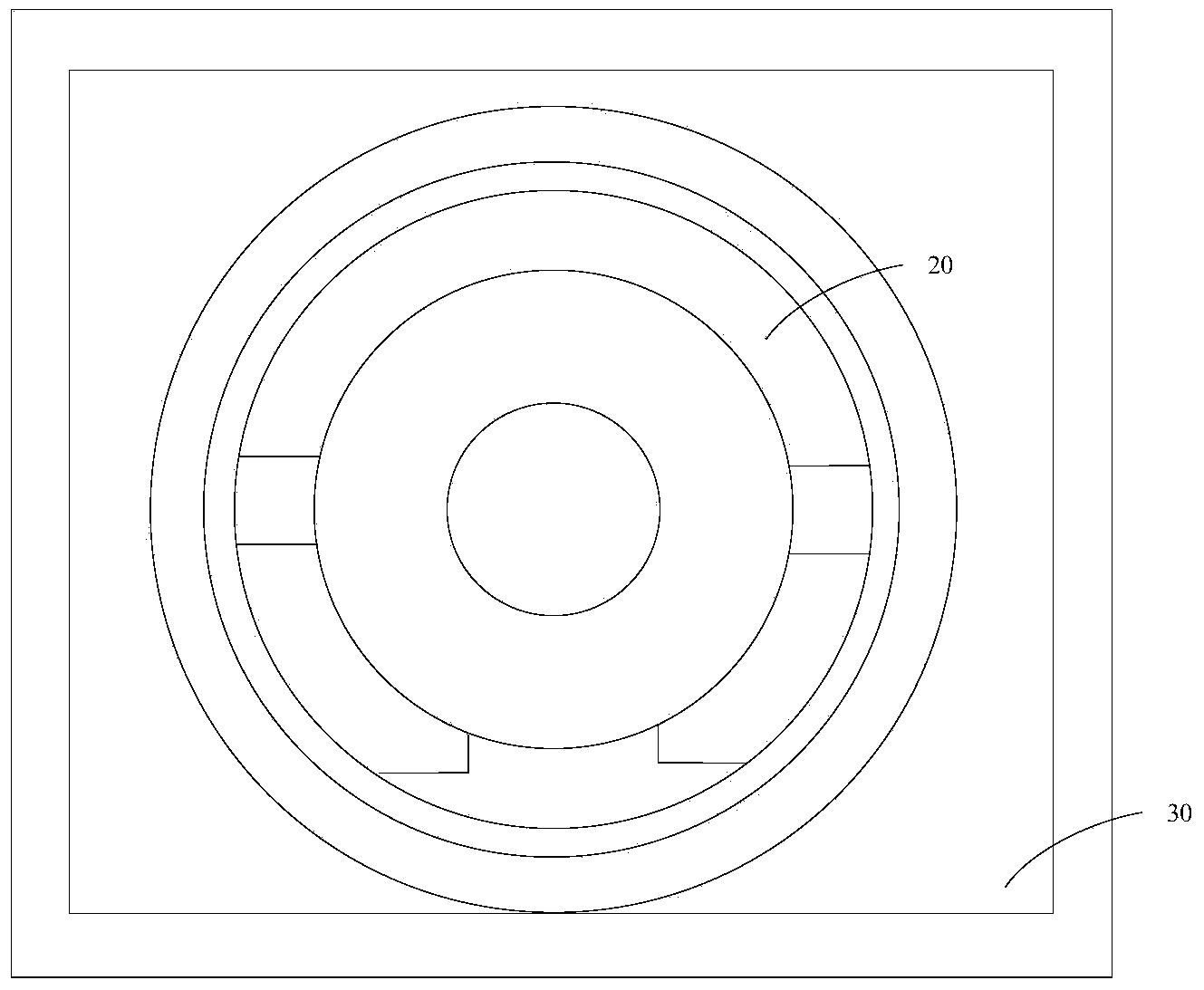

[0038] This embodiment provides a camera module, its plan view is as follows figure 2 As shown, it includes a lens 20 and a motor 30 , wherein the lens 20 includes a lens barrel and a lens fixed inside the lens barrel, and the lens may be one lens or a lens group composed of multiple lenses. The motor 30 can fit the lens 20 and drive the lens 20 to move, so as to realize the focusing function of the camera module.

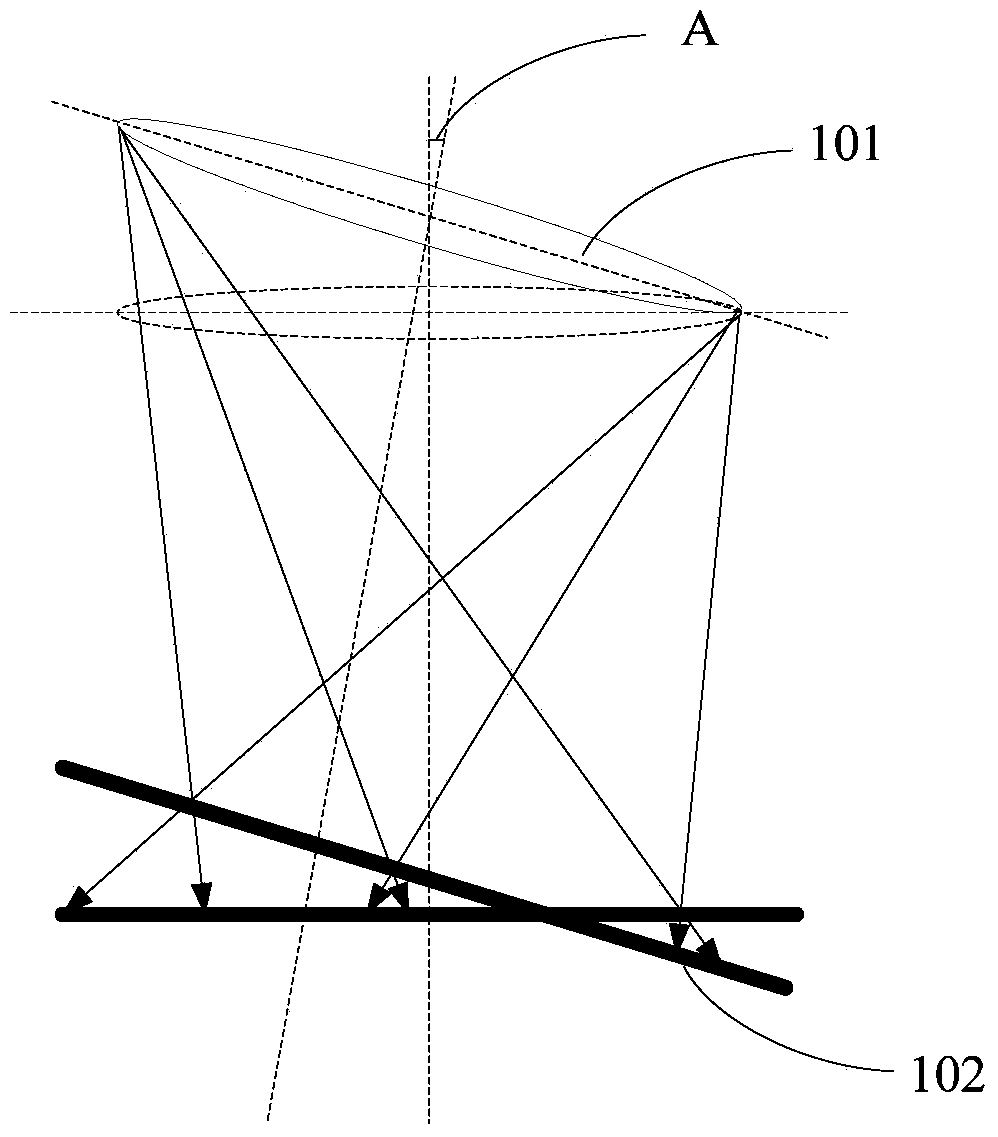

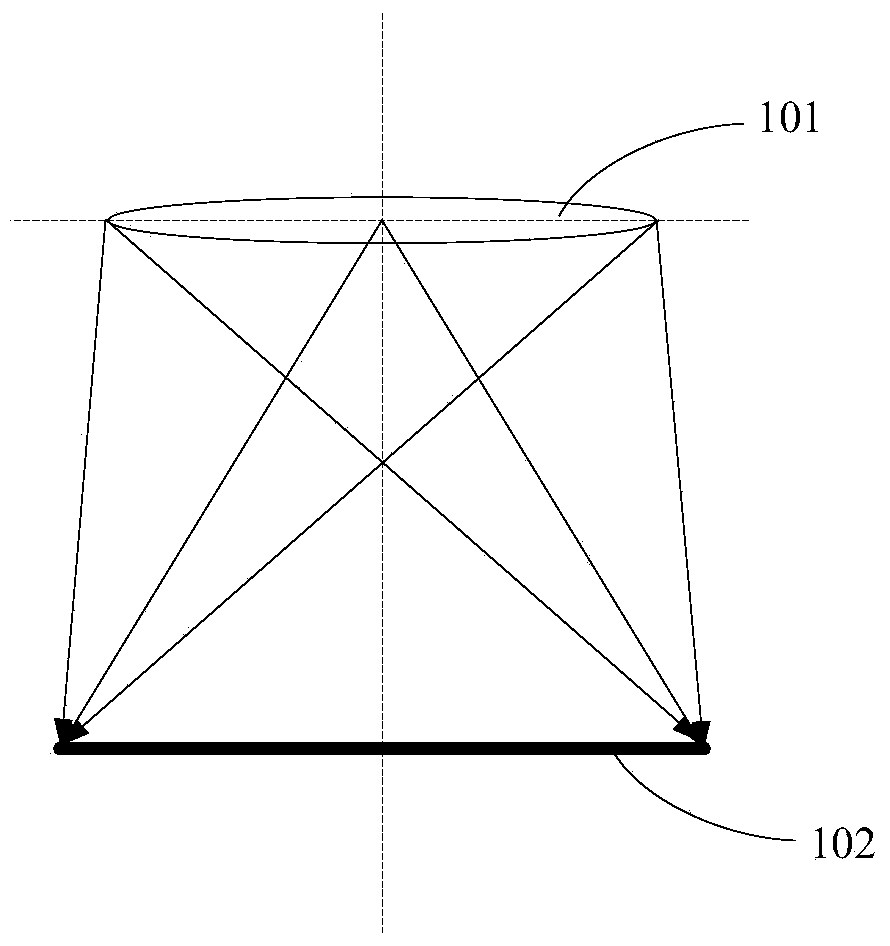

[0039] In this embodiment, the section view of the camera module is as follows image 3 As shown, the outer side of the lens barrel 201 of the lens 20 has a fixed strip 203, and the fixed strip 203 can continuously go around the lens barrel 201 for a week, and can also be discontinuously arranged on a circle outside the lens barrel 201. In any case, the fixed strip 203 are located on the circumference of a cross section outside the lens barrel 201, of course, the specific position of the fixing bar 203 can be set according to the actual situation, the present inv...

Embodiment 2

[0048] The structure of the camera module provided in this embodiment is substantially the same as that provided in Embodiment 1, the difference is that the inner side of the sleeve of the motor does not have a fixing groove, and the lens is movably fitted in the motor through a fixing bar. The sleeve surface of the motor to adjust the tilt of the lens.

[0049] The sectional structure diagram of the camera module provided in this embodiment, such as Figure 4 As shown, the fixing bar 203 of the lens 20 is movably fitted on the sleeve 31 of the motor, and the lens 20 is supported by the peripheral edges of the sleeve 31 . Since the lens 20 is movable, the inclination between the lens 20 and the photosensitive chip 40 at the bottom can be adjusted.

[0050] The adjustment process of the inclination of the lens 20 is: install the lens 20, the photosensitive chip 40 and the flexible circuit board, etc., and take a test picture, and then adjust the inclination of the lens 20 acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com