Method and device for loosening, conditioning and flavouring tobacco

A tobacco, loose technology, applied in the direction of tobacco, preparation of tobacco, application, etc., can solve the problem of lack of rotating drums, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

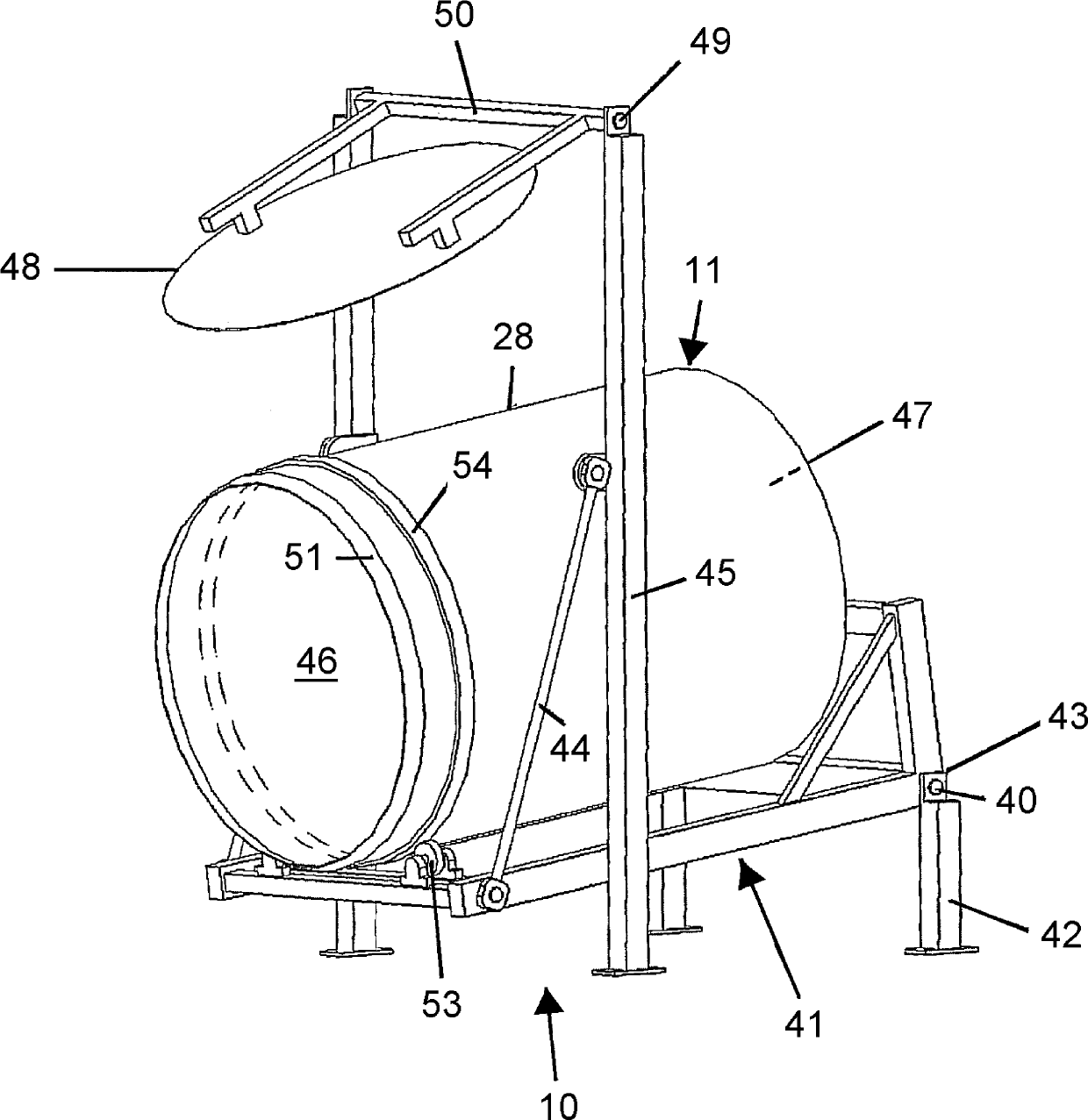

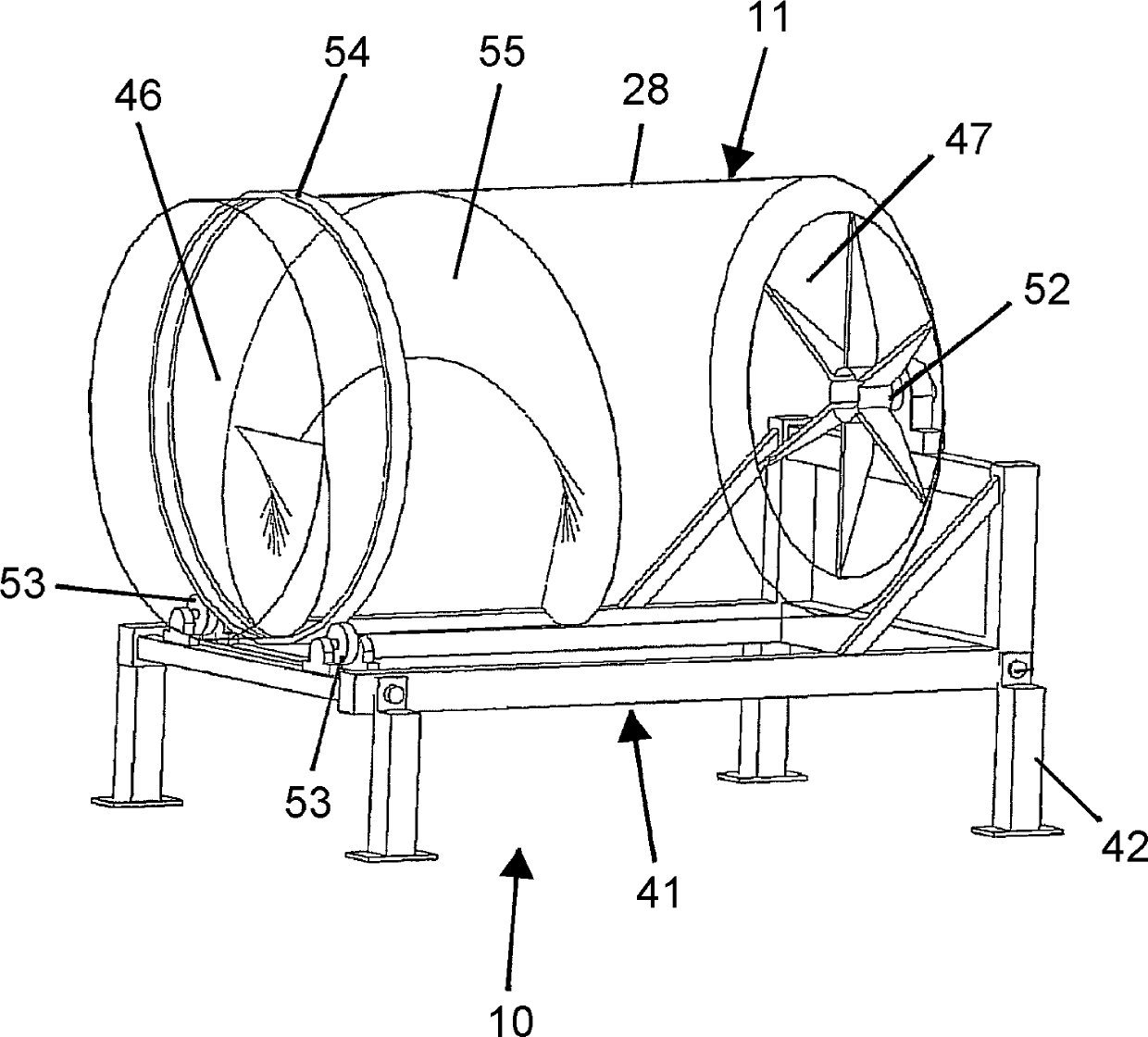

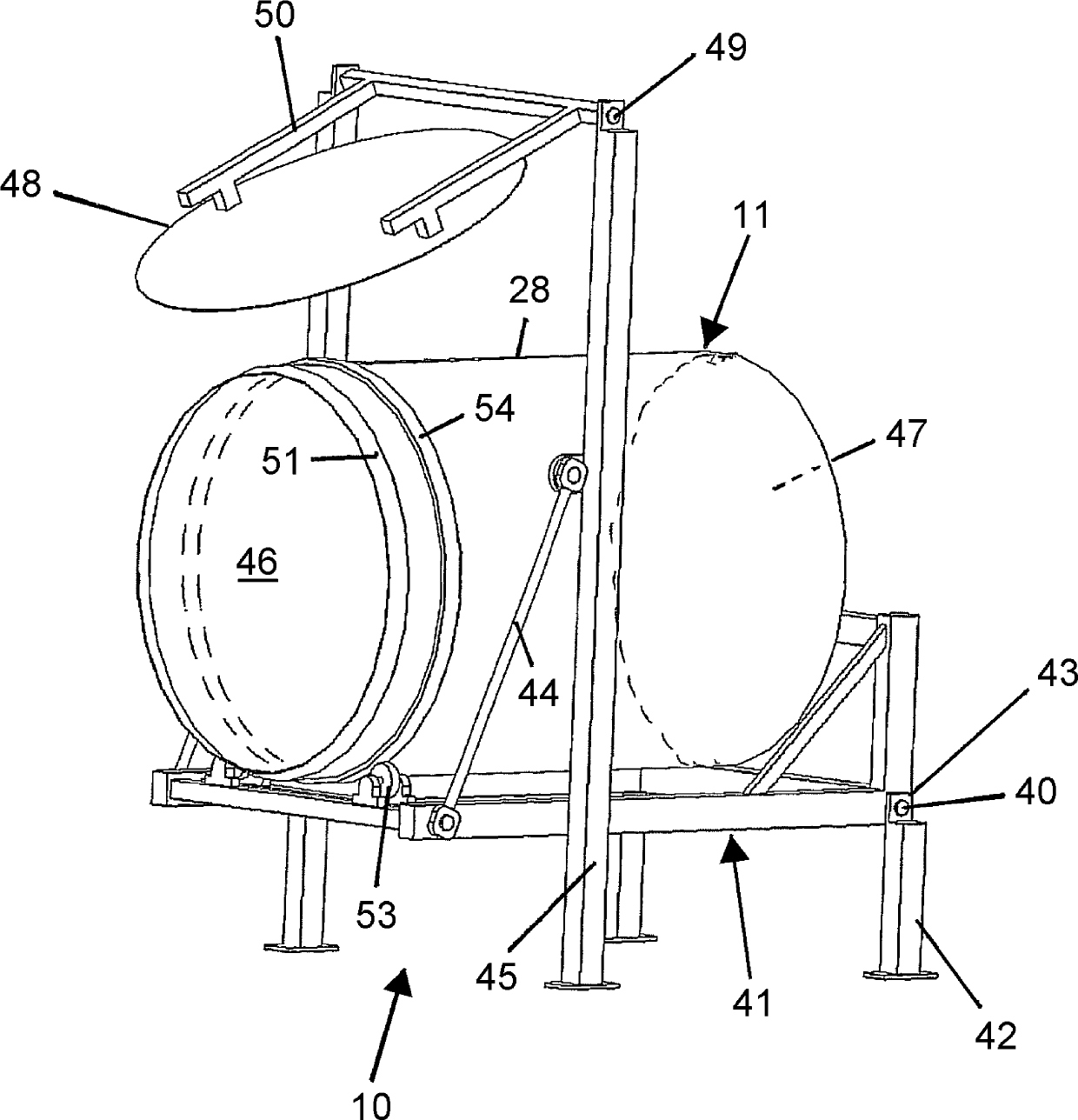

[0020] Below with the help of figure 1 and 7 The basic operating principle of the device 10 according to the invention and the functional sequence of the method according to the invention are explained.

[0021] The device 10 for treating tobacco comprises a rotatably supported drum 11 which can be figure 1 A rotary drive not shown in is placed in rotation. In this embodiment, the drum 11 comprises an inlet 12 in the end wall 13 of the generally cylindrical drum 11 and an inlet 12 in the opposite end wall 15 of the drum 11 . Separate exit 14. The inlet 12 can be closed by means of a cover 20 and the outlet 14 can be closed by means of a cover 21 . The lids 20 , 21 can be connected or can be connected to the drum 11 in a suitable manner, for example by hinges, by means of screw connections or in other ways.

[0022] After removing the wrapping of the tobacco mass 16 (in Figure 7 In step S1 ), in optional step S2 the tobacco mass is weighed and / or crushed if necessary in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com