A feeding mechanism for a three-roller mill

A mill and mill technology, which is applied in grain processing and other directions, can solve the problems of difficulty and labor in discharging or discharging materials for operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

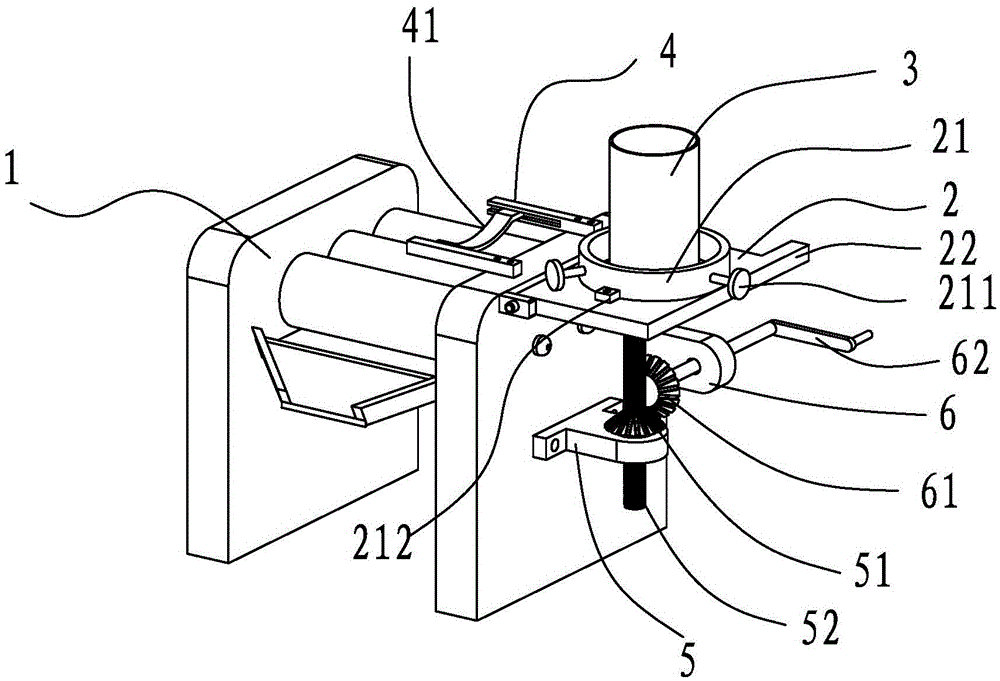

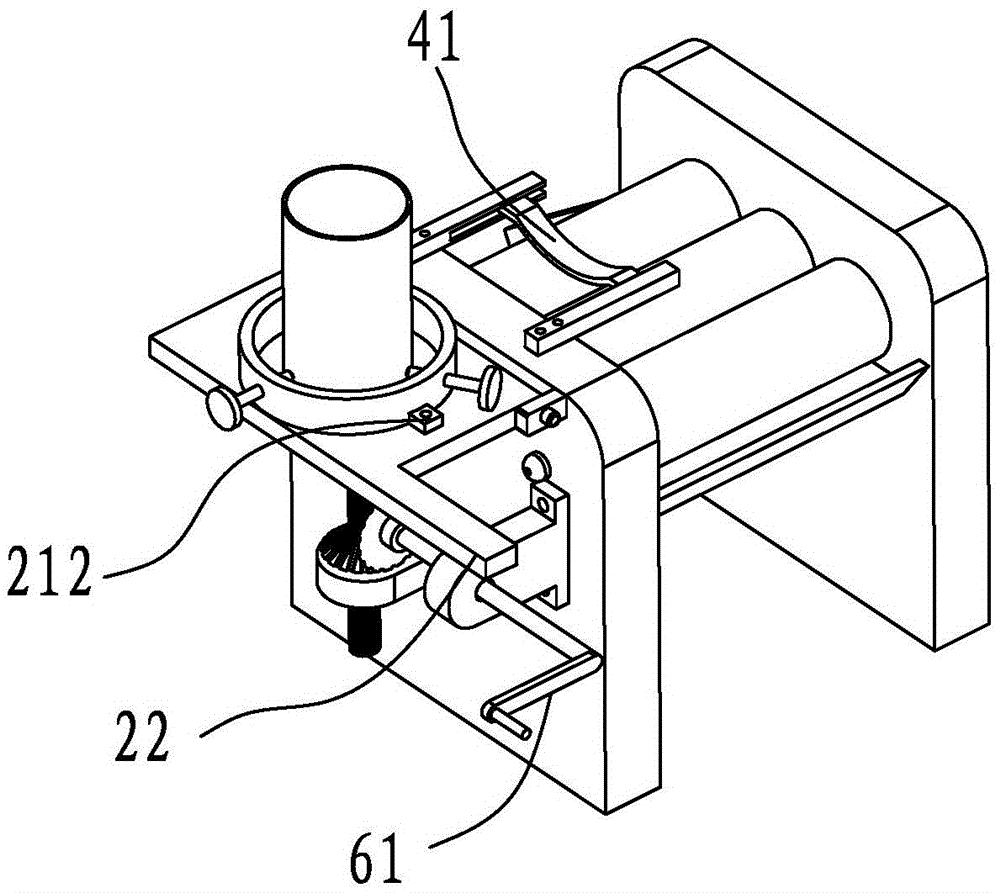

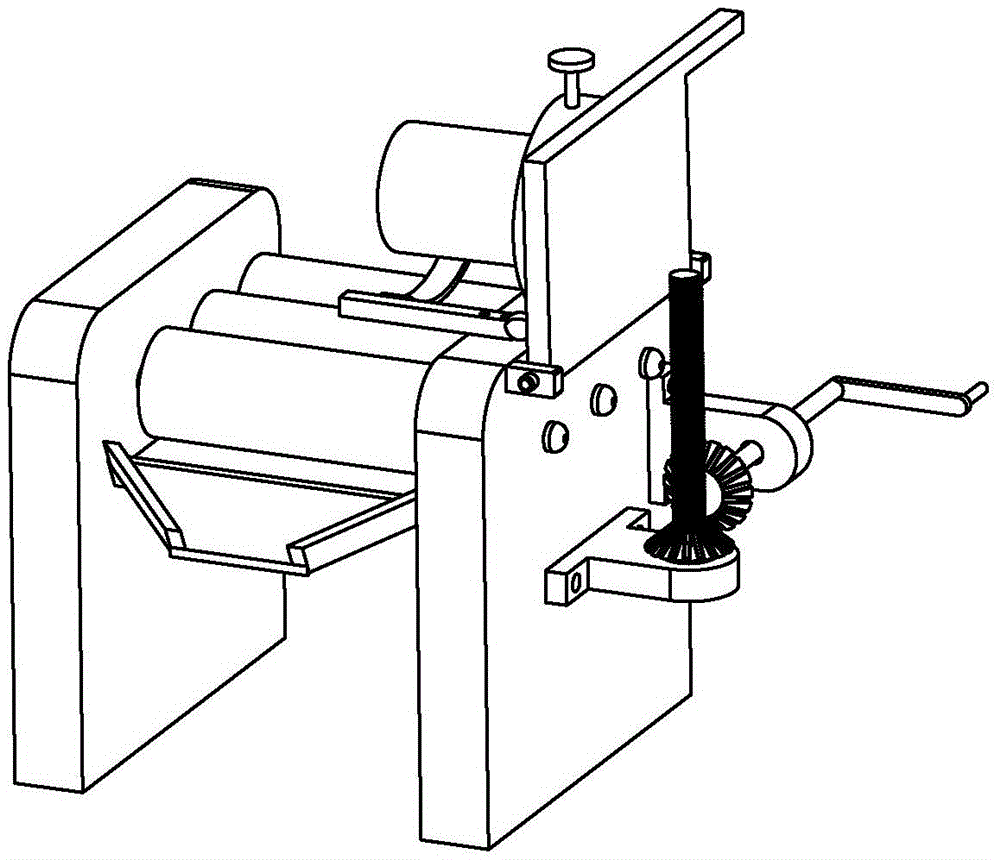

[0012] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0013] like Figure 1 to Figure 3 As shown, a discharge mechanism of a three-roll mill includes a mill main body 1, the mill main body includes cylinders arranged on both sides, three rollers are hinged between the cylinders, and the mill A discharge pallet 2 is hinged on the top of the outer side of the main body of the machine, and a handle 22 extends from the rear of the discharge pallet. The operator can hold the handle to control the rotation of the discharge pallet, and the center of the discharge pallet is fixed The limit steel ring 21, the material barrel 3 is placed in the limit steel ring, the shape of the limit steel ring is set into a cylindrical shape, which matches the shape of the material barrel, but the material barrel is distinguished by volume, and the material barrel with a large volume The diameter is relatively large, and on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com