Adjusting aluminum strip chamfering device

A chamfering device and adjustable technology, which is applied in the field of adjustable aluminum strip chamfering devices, can solve the problems of reducing production efficiency and wasting raw materials, and achieve the effects of improving production efficiency, avoiding repeated stamping, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

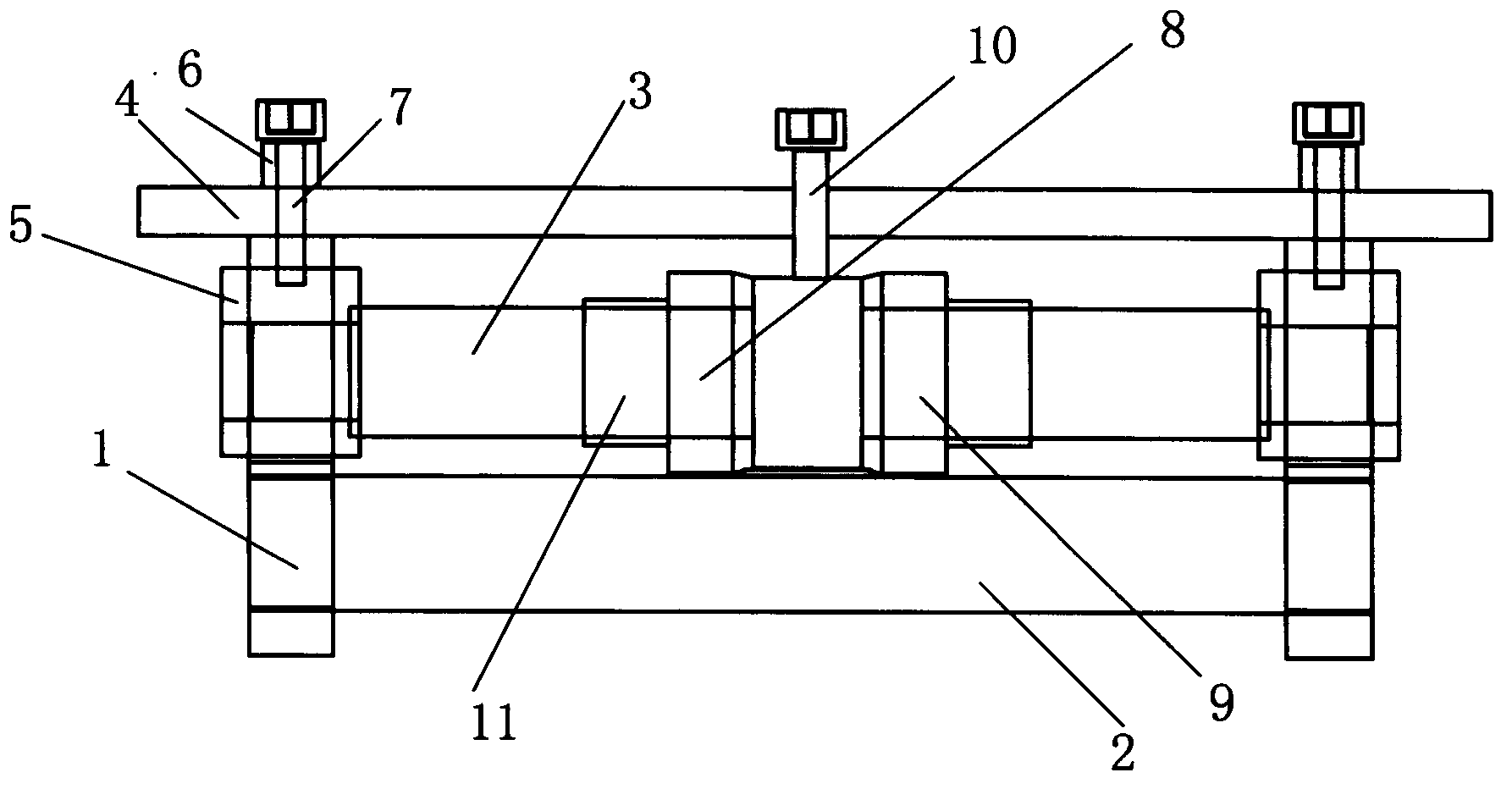

[0018] Such as figure 1 The shown adjustable aluminum strip chamfering device includes a device bracket 1, which is different in that: the device bracket 1 used in the present invention is provided with a lower roller 2. At the same time, a central shaft 3 is arranged above the lower roller 2 , and an upper pressing plate 4 is arranged above the central shaft 3 . Thus, a chamfering processing area is formed between the lower roller 2 and the central shaft 3, which facilitates the processing of the aluminum strip. Moreover, in order to be able to adjust in real time with different working conditions and usage requirements, and realize the implementation of multiple specifications of the same chamfering device, both ends of the central axis 3 are provided with side adjustment components. Of course, considering the multi-directionality of the adjustment, a central adjustment assembly is also provided in the middle of the central axis 3 .

[0019] According to a preferred embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com