Caster assembly device, pressing device and caster installation method

A technology of assembly device and pressing device, which is applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that the assembly speed cannot keep up with the rhythm of the assembly line, the labor intensity of assembly workers is high, and the installation accuracy is reduced, so as to provide installation Accuracy, reduce labor intensity and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

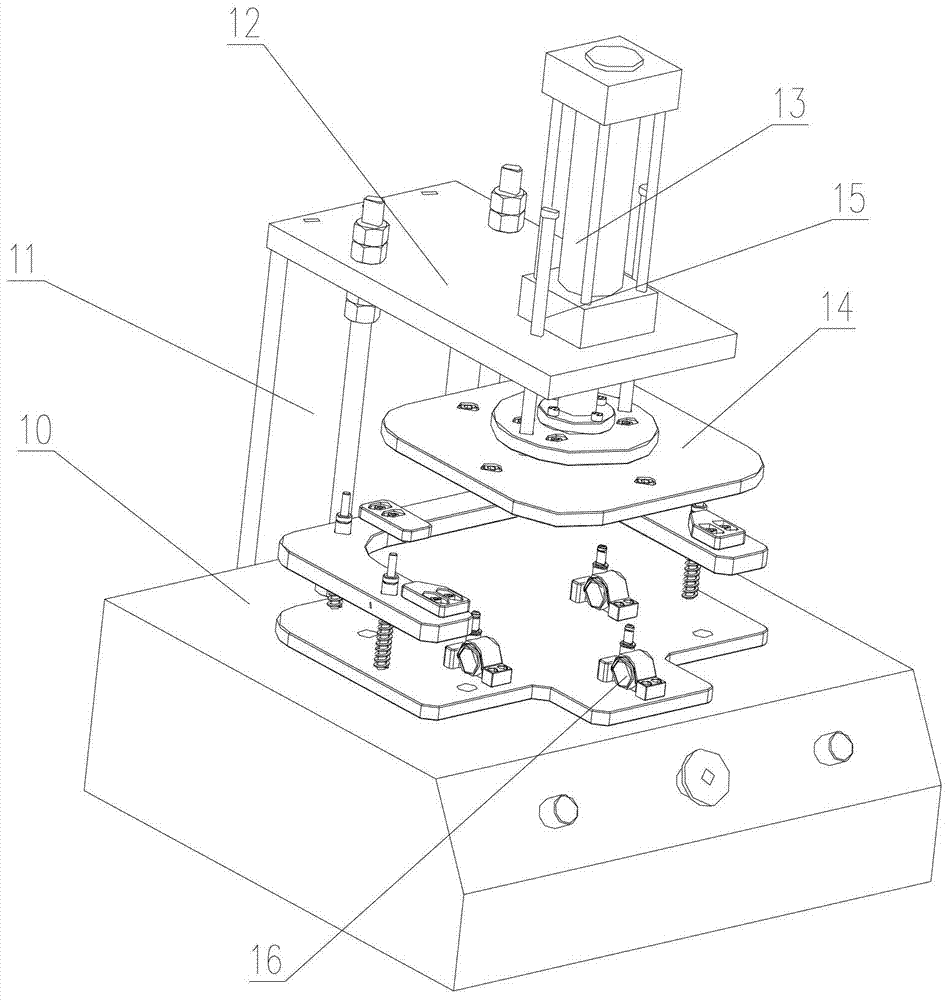

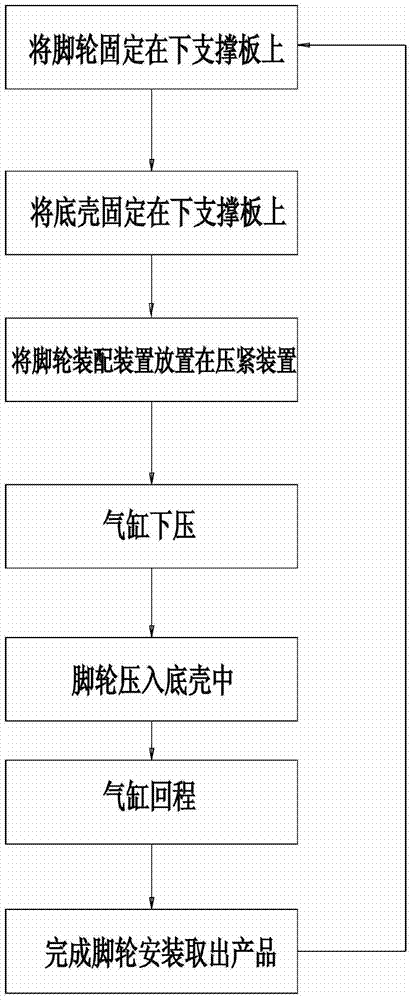

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0033] In this embodiment, the application provides a caster assembly device, a pressing device and a caster installation method, which are suitable for the installation of casters in the bottom case of dehumidifiers, etc., which simultaneously and automatically press the casters into the bottom case , can effectively improve the installation efficiency and accuracy of casters and reduce the labor intensity of workers.

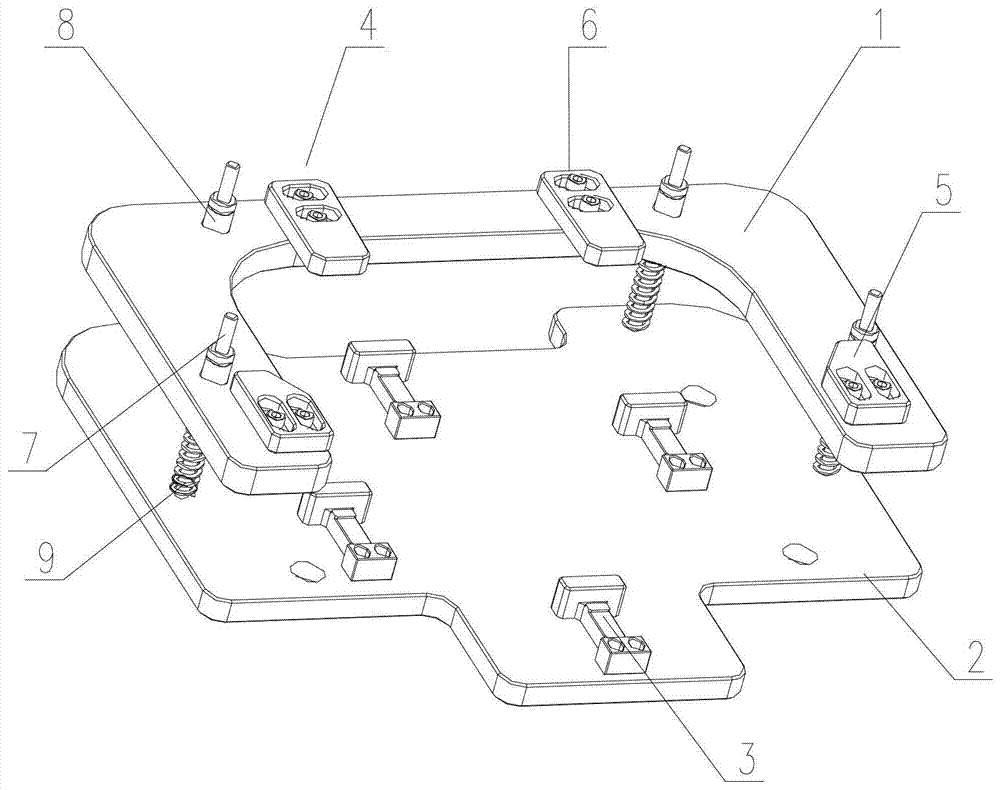

[0034] Such as figure 1 , Figure 4 As shown, a caster installation device includes an upper support plate 1 and a lower support plate 2, wherein the upper support plate 1 is vertically slidable on the upper part of the lower support plate 2 through a reciprocating device, and the upper support plate 1 can be reciprocated Under the action of the device, it resets after the casters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com