Sheet-fed printing paper cutting method

A printing method and technology for printed matter, applied in printing, printing presses, flatbed presses, etc., can solve the problems of 1-2 hours or even longer time, waste of paper raw materials, calculation errors, etc., to reduce plate making Cost, improve production efficiency, reduce the effect of error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

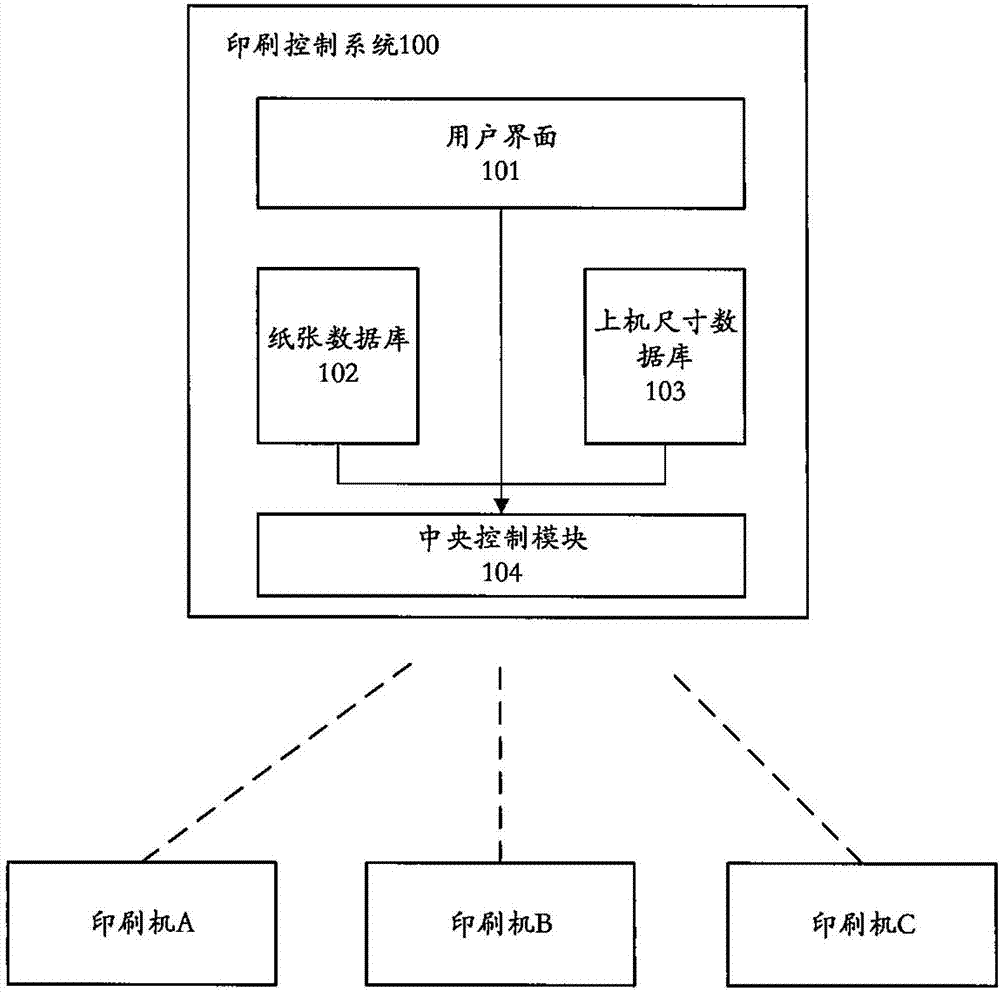

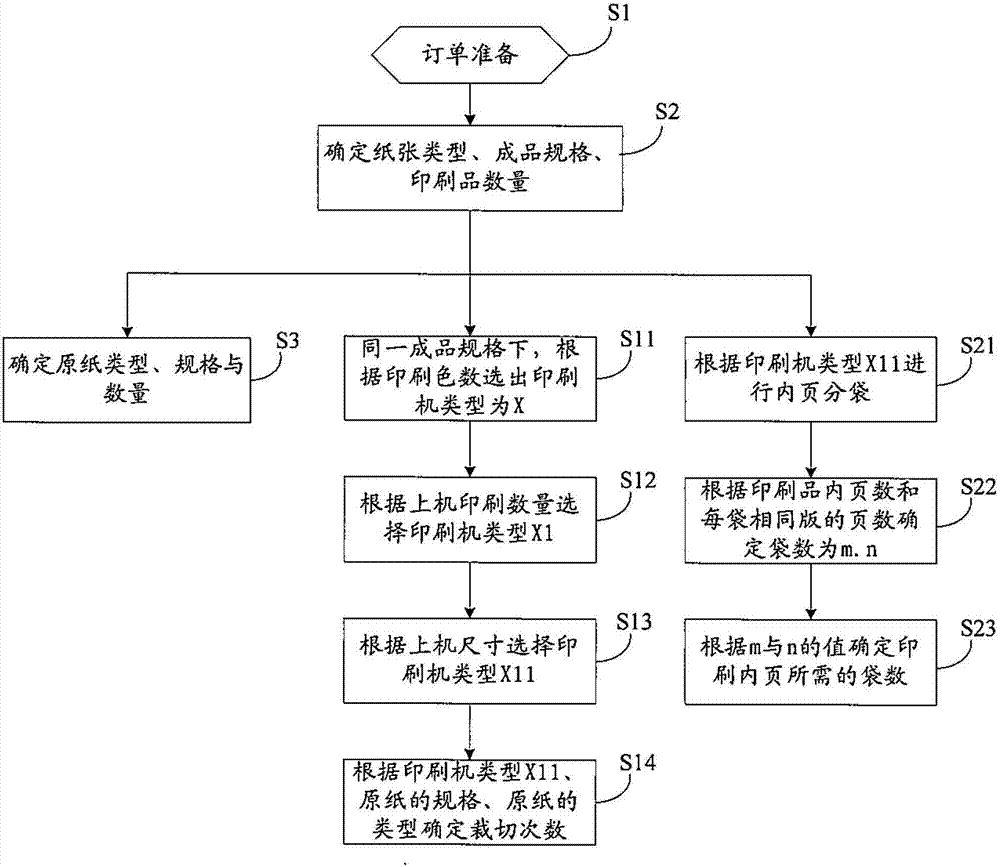

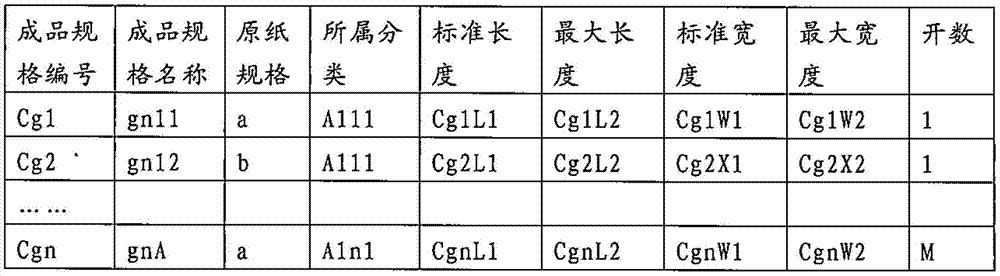

Method used

Image

Examples

Embodiment Construction

[0038] The making and using of the embodiments are discussed in detail below. It should be understood, however, that the specific embodiments discussed are merely illustrative of specific ways to make and use the invention, and do not limit the scope of the invention.

[0039] In the printing process of books and magazines, the inner page printing method of multiple pages of the same paper is to assemble a large folded hand page with multiple page number symbols for printing. This large folded hand page is called a bag, and then the After the bag of paper is printed on both sides, it is folded into a folding machine and then bound into a book. A bag of paper may have 2 pages, 4 pages, 8 pages, 16 pages, and 32 pages depending on the size of the finished book or magazine. Therefore, different page splitting methods will result in the same number of pages and the same specification. The number of bags that the inner pages are divided into will vary. In cover printing, sheet-fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com