A tire pressure monitoring system real vehicle performance test system

A tire pressure monitoring and testing system technology, applied in tire measurement, tire parts, vehicle components, etc., can solve the problems that the real vehicle performance test cannot be realized, and achieve the effect of high precision and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

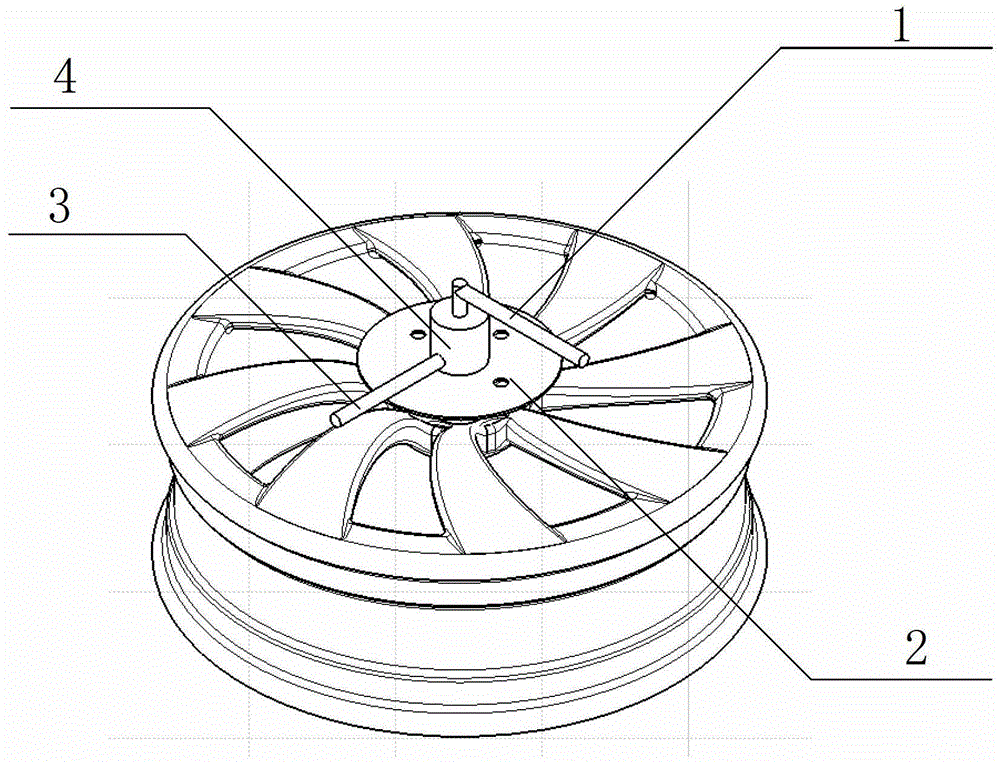

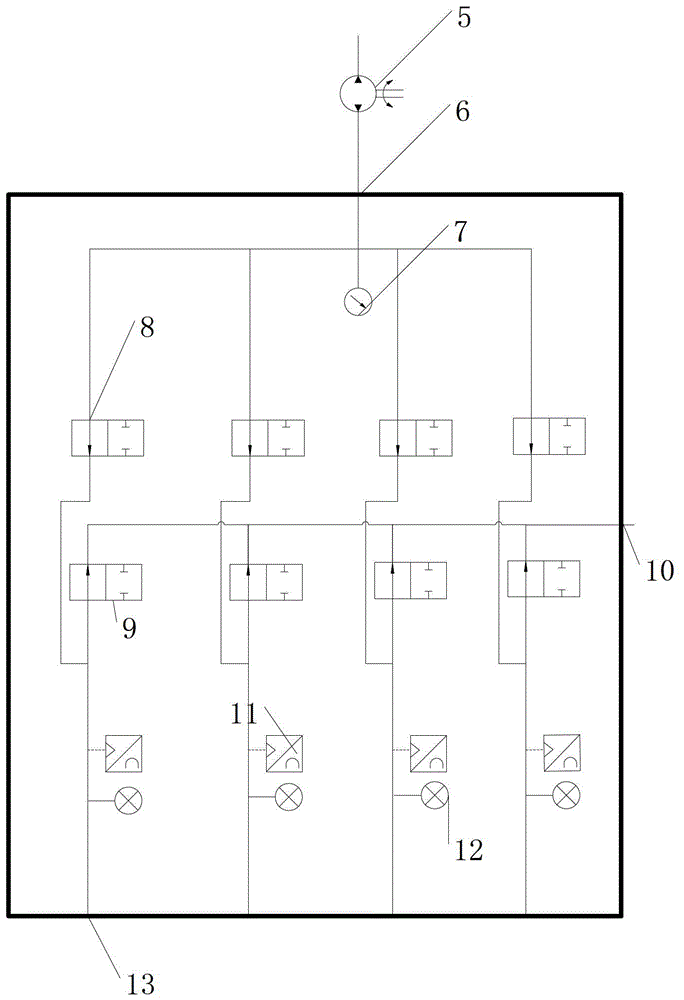

[0041]A kind of tire pressure monitoring system actual vehicle performance test system of the present invention will be further described below in conjunction with accompanying drawing and embodiment:

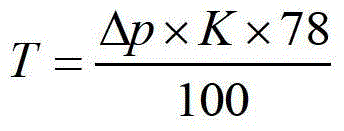

[0042] A real vehicle performance test system of a tire pressure monitoring system includes an actuator and a controller. Among them, the actuator measures the internal pressure of all tires in real time, and sends the pressure signal to the controller, and realizes the tire pressure signal under the driving state under the control of the control signal of the controller. The controller receives the tire pressure signal sent by the actuator, processes it according to the set control flow, sends the control signal to the actuator, controls the action of the actuator, and completes the measurement and pressure adjustment of the tire pressure.

[0043] In this embodiment, the actuator includes a wheel assembly and a pressure adjustment assembly. The wheel assembly passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com