Filling device, filling machine and method for filling container

A technology of filling device and filling machine, which is applied in the direction of bottling machine, filling device cleaning, packaging, etc., and can solve heavy problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

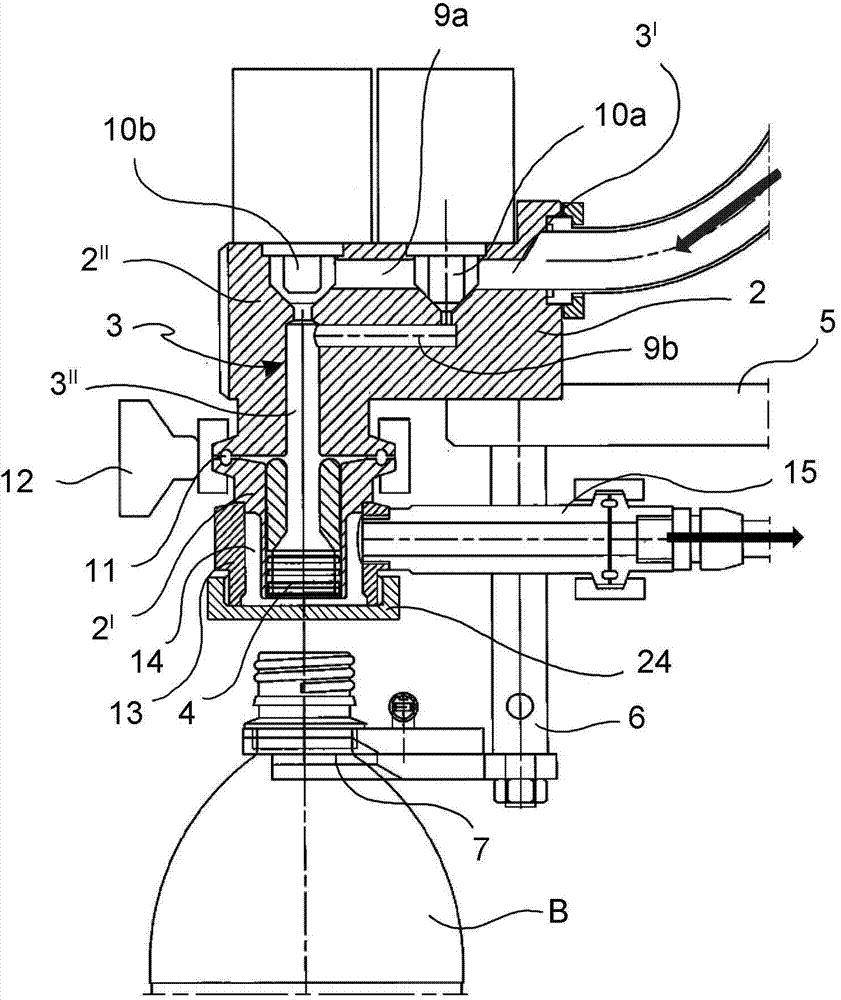

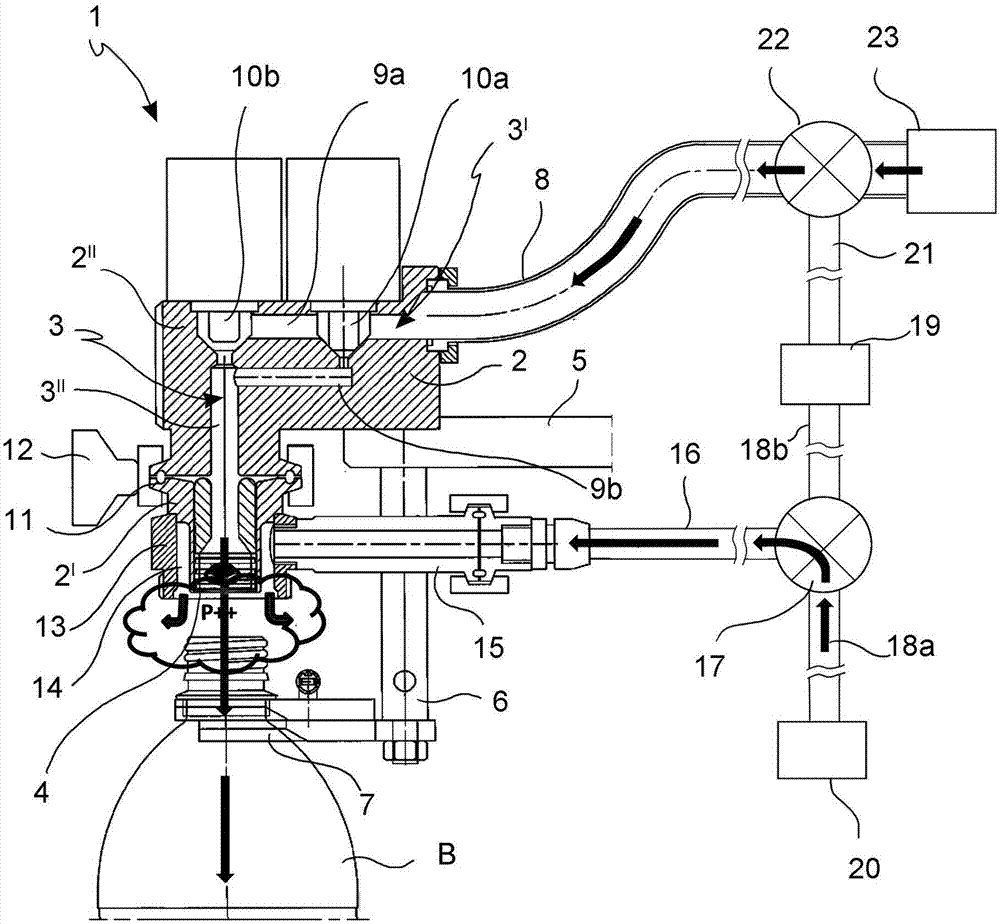

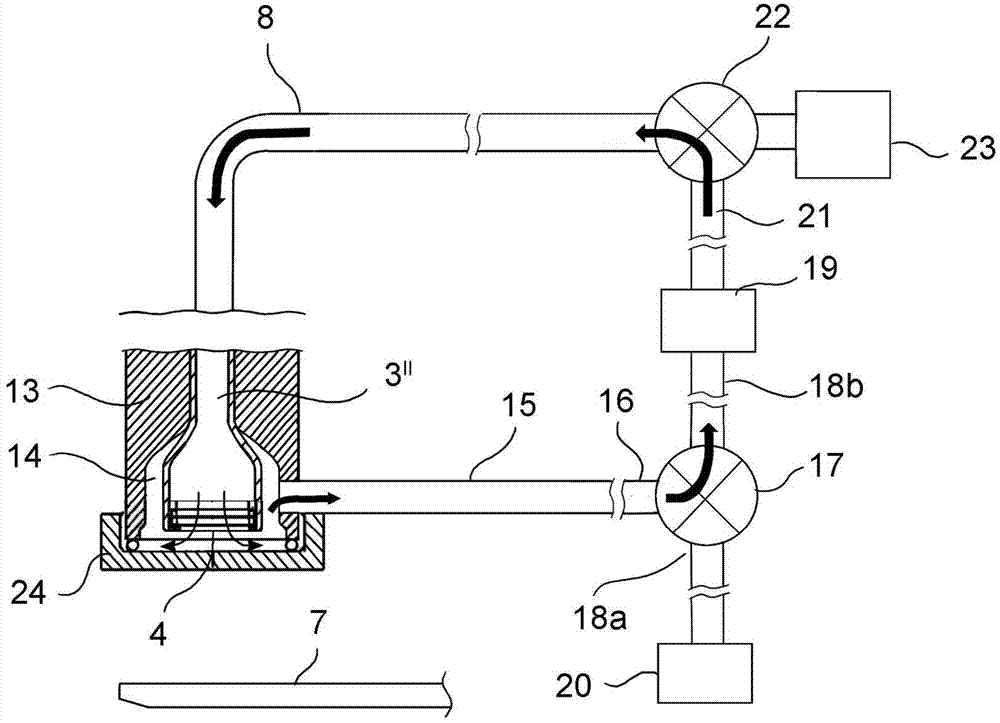

[0016] With reference to the accompanying drawings, the filling device according to the invention, indicated generally by the numeral 1 , comprises a body 2 in which a distribution duct 3 for the filling fluid is obtained. The distribution duct 3 terminates in the lower part with a distribution nozzle 4 .

[0017] The body 2 is fixed to the filling machine (not shown) by means of support rods 5 . The support arm 6 for the bottle B is also fixed to the support rod 5 . The support arm 6 is L-shaped and terminates in a fork 7 capable of engaging the neck of the bottle B .

[0018] The distribution pipe 3 is connected to a filling fluid supply pipe 8 .

[0019] In some embodiments, the distribution duct 3 comprises a first substantially horizontal section 3' and a second vertical section 3" leading to the distribution nozzle 4. In some embodiments, the first section 3' comprises two Two substantially parallel branches 9a, 9b cut off by the valve means 10a, 10b. The two branches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com