A seawater desalination system using waste heat of flue gas

A flue gas waste heat and seawater technology, which is applied in seawater treatment, general water supply conservation, water/sewage treatment, etc., can solve problems such as regular maintenance, easy scaling, and poor heat transfer effect, so as to reduce energy consumption and cost, Efficient utilization and emission reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

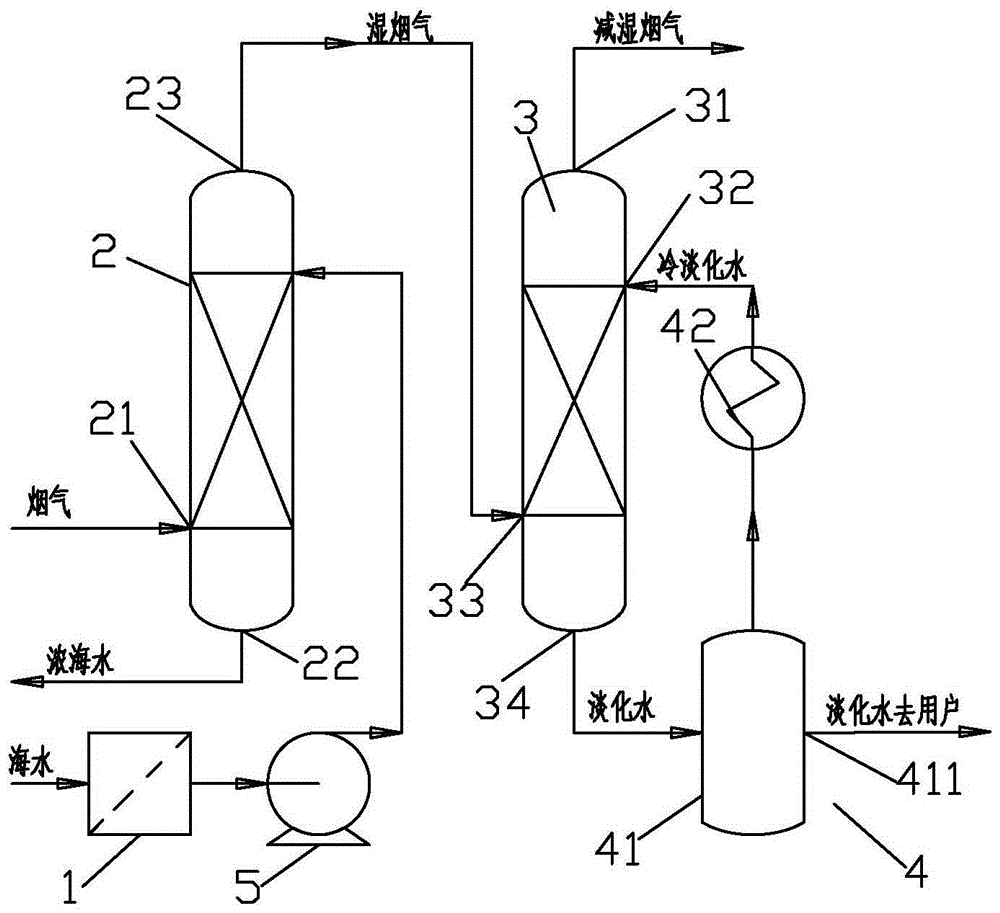

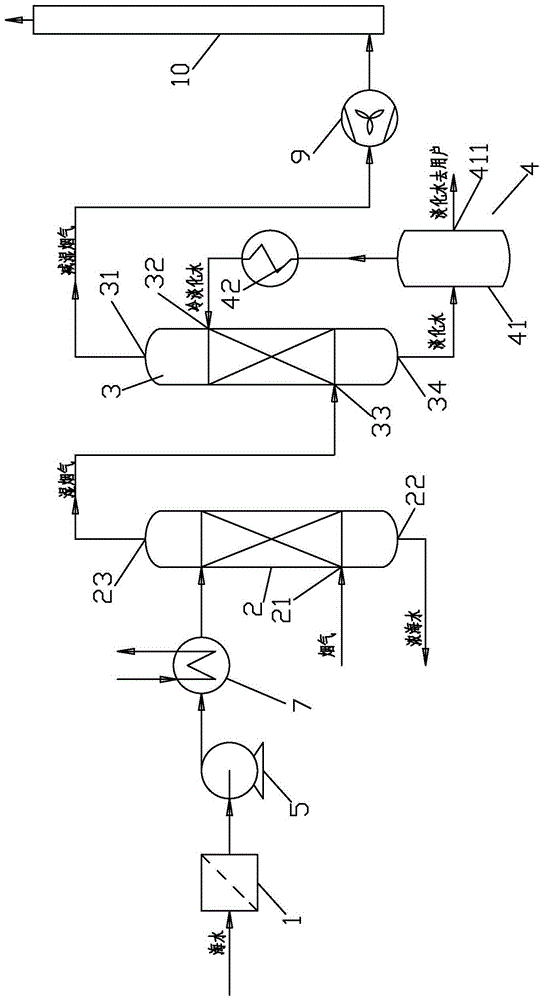

[0034] Embodiment 1: as figure 2 As shown, this embodiment is an integrated waste heat utilization integrated seawater desalination system suitable for thermal power plants. The system includes: seawater filtering device 1 , seawater pump 5 , condenser 7 , humidification tower 2 , dehumidification tower 3 , freshwater storage tank 41 , freshwater cooling device 42 , fan 9 , and chimney 10 .

[0035] In this embodiment, the seawater is pumped to the condenser of the steam turbine by the seawater pump after passing through the filter device for heat exchange; Humidification; after humidification, the flue gas enters the dehumidification tower to reduce temperature and dehumidification, and the water vapor in the flue gas is partially condensed and recovered as desalinated water to the desalination water tank; part of the fresh water in the desalination water tank is used as cooling water after passing through the fresh water cooling device as The cooling water of the dehumidif...

Embodiment 2

[0037] Embodiment 2: as image 3 As shown, this embodiment is an integrated waste heat utilization integrated seawater desalination system suitable for thermal power plants. The system includes: seawater filtering device 1, seawater pump 5, condenser 7, seawater heat exchanger 8, humidification tower 2, dehumidification tower 3, freshwater storage tank 41, freshwater cooling device 42, fan 9, and chimney 10.

[0038] In this embodiment, the seawater passes through the filter device and is pumped to the steam turbine condenser by the seawater pump for heat exchange; then the seawater enters the thick and light seawater heat exchanger for further heat exchange to increase the seawater temperature; the fully heat-exchanged seawater is sent to the humidification tower The heat and mass transfer is carried out in contact with the flue gas discharged from the boiler, and the flue gas is humidified; after humidification, the flue gas enters the dehumidification tower to reduce temper...

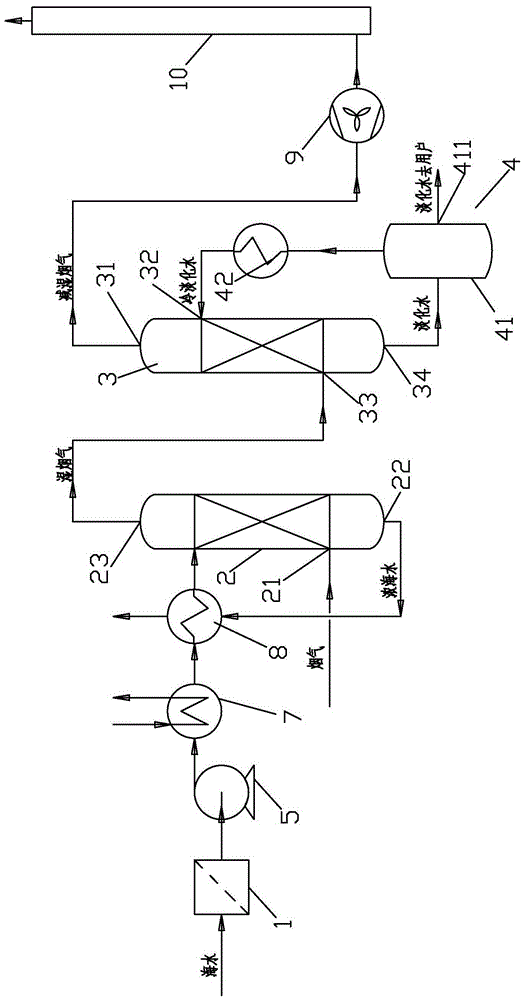

Embodiment 3

[0040] Embodiment 3: as Figure 4 As shown, this embodiment is an integrated waste heat utilization integrated seawater desalination system suitable for thermal power plants. The system includes: seawater filtering device 1, seawater pump 5, condenser 7, seawater heat exchanger 8, humidification tower 2, dehumidification tower 3, freshwater storage tank 41, freshwater cooling device 42, fan 9, and chimney 10.

[0041] In this embodiment, the seawater is sent to the steam turbine condenser) and the fresh water cooling device for heat exchange after passing through the seawater pump through the seawater pump; then the seawater from the seawater condenser enters the thick and light seawater heat exchanger) for further heat exchange to increase the seawater temperature ; After sufficient heat exchange, the seawater is sent to the humidification tower to conduct heat and mass transfer in contact with the flue gas discharged from the boiler to humidify the flue gas; after humidifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com