Low-noise belt transmission device

A belt-driven, low-noise technology, which is applied in hoisting devices, portable lifting devices, belts/chains/gears, etc., can solve the problems of surprisingly loud noise and polluting the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

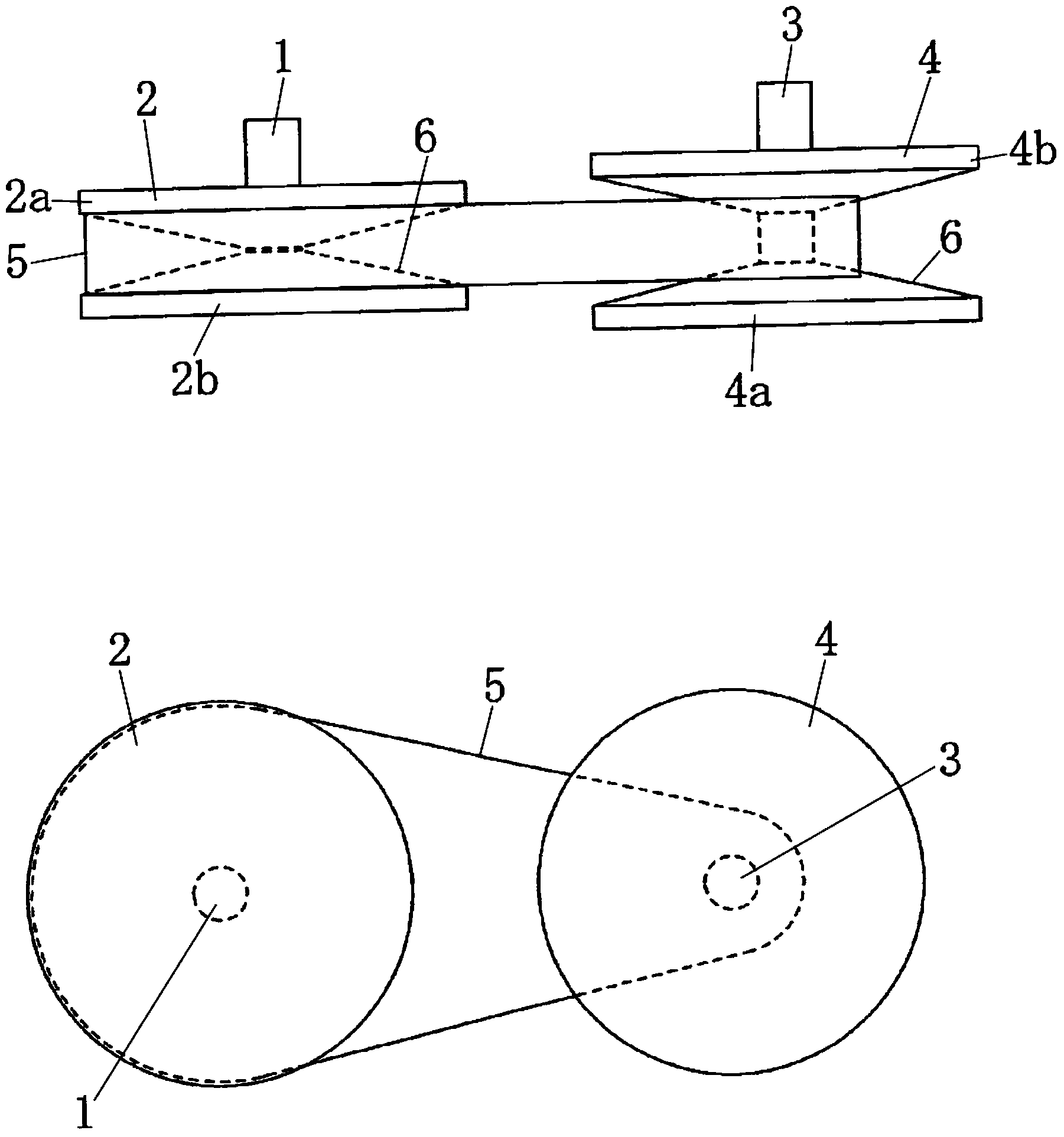

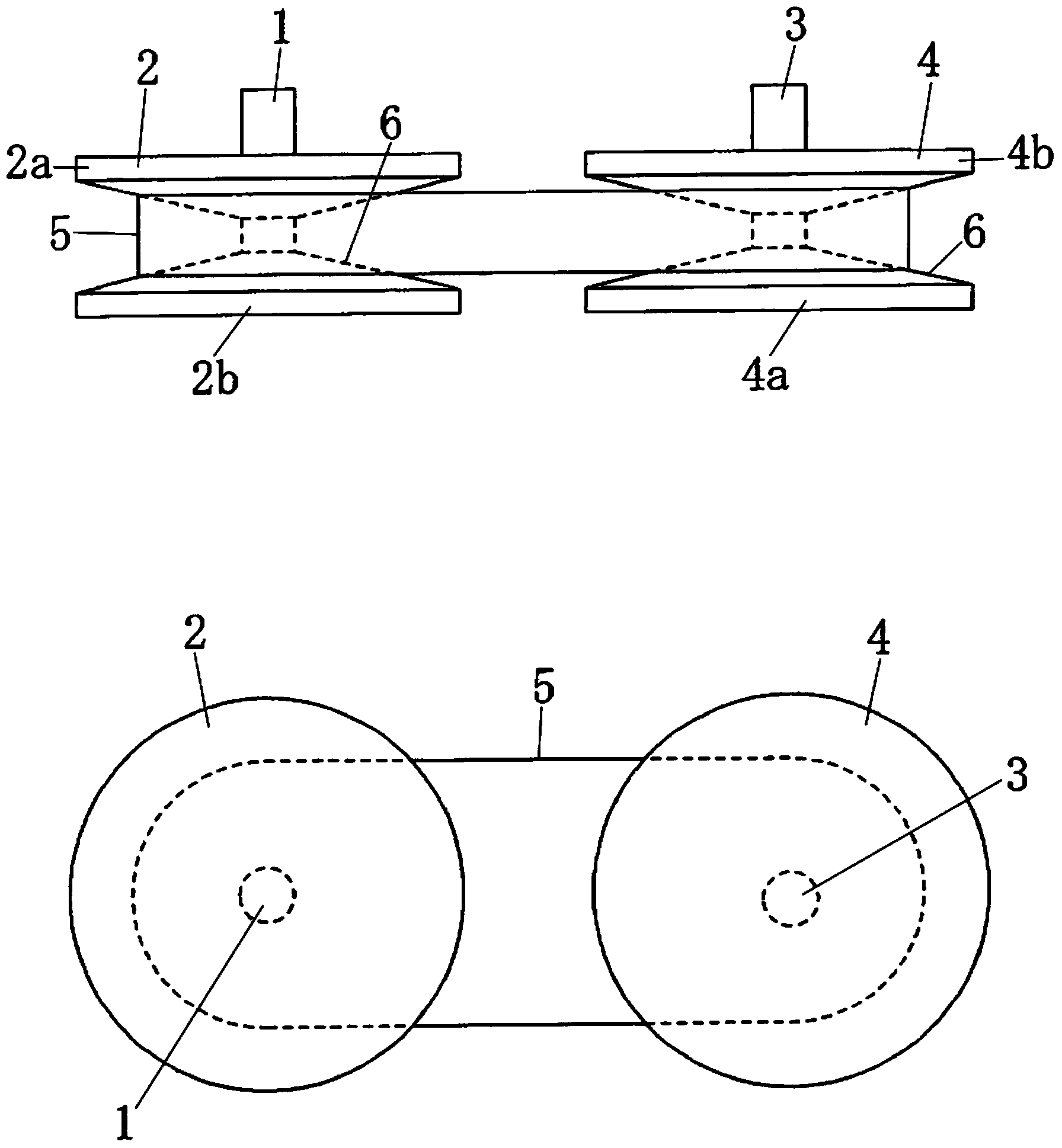

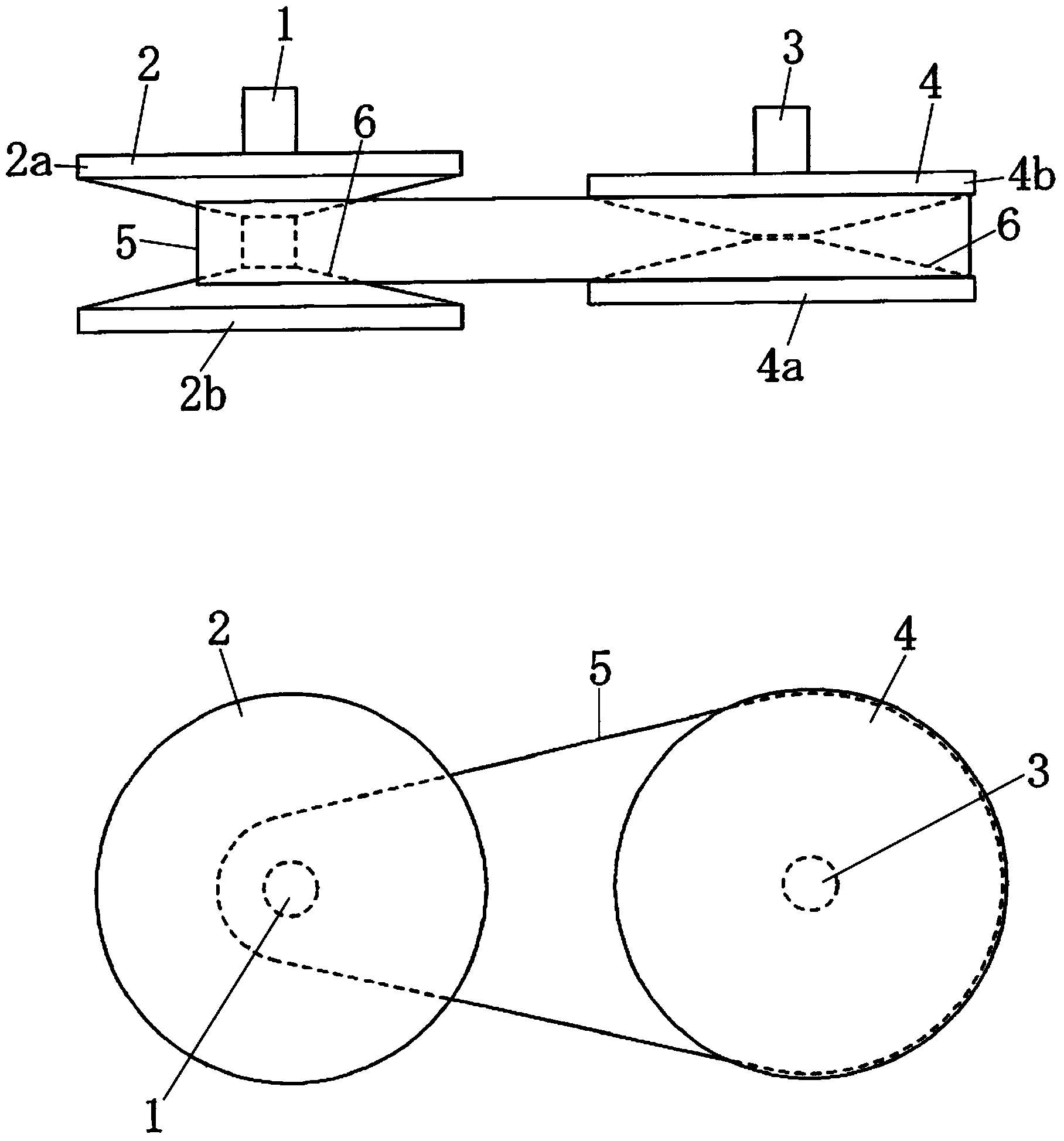

[0011] See attached Figure 1~3 , a low-noise belt transmission device, including a driving shaft (1) and a driven shaft (3), the driving shaft (1) is provided with a driving pulley (2), and the driven shaft (3) is provided with a slave The driving pulley (4), the driving pulley (2) and the driven pulley (4) are all composed of a fixed half-wheel (2a, 4a) and a movable half-wheel (2b, 4b) which are divided into two parts, The four half-wheels are all in the shape of a top, with the same size and taper. The end faces are flat and have flanges, and the holes in the center are respectively pierced on the shafts (1, 3). The cones face each other, but the positions (a, b) Interchange and form the pulley groove (6), the fixed half-wheels (2a, 4a) rotate together with the shaft, and the movable half-wheels (2b, 4b) can move. The purpose of the above-mentioned technical measures is to change the belt pulley groove from the traditional fixed structure to a half-fixed, half-movable tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com