Marine high-sound-insulation floating floor structure

A high-separation, marine-used technology, applied to hull decks, hull panels, hulls, etc., to achieve reasonable overall structure settings, excellent shock and noise reduction effects, and reduced noise decibels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

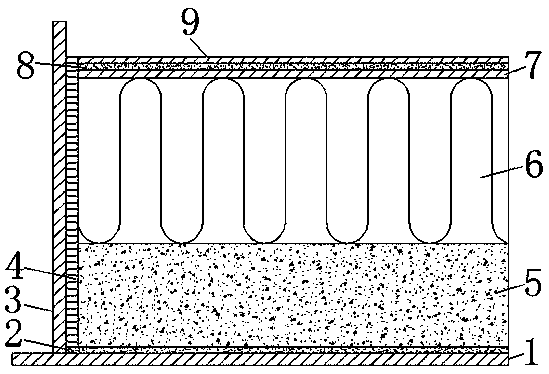

[0023] Such as figure 1 As shown, the marine high sound insulation floating floor structure of the present invention includes a damping coating I2 on the steel deck 1, and a ceramic wool partition strip 4 on the damping coating I2 that is close to the steel enclosure 3 , a fire-resistant deck coating layer 5 is provided on the damping coating I1 between the ceramic wool partition strips 4, a rock wool board 6 is provided on the fire-resistant deck coating layer 5, and a rock wool board 6 is provided on the rock wool board 6. There is galvanized steel plate I7, damping coating II8 is provided on said galvanized steel plate I7, galvanized steel plate II9 is provided on said damping coating II8, said damping coating I2, fire-resistant deck coating layer 5, rock The thickness ratio of cotton plate 6, galvanized steel plate Ⅰ7, damping coating Ⅱ8 and galv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com