Novel sealing structure for transmission shaft protective sleeve

A sealing structure and transmission shaft technology, applied in the field of auto parts, can solve problems such as the coaxiality of the water inlet of the spline pair, difficulty in sliding the transmission shaft, eccentric wear of the oil seal, etc., which is beneficial to the arrangement and use of the lips and has a simple structure , the effect of improving the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

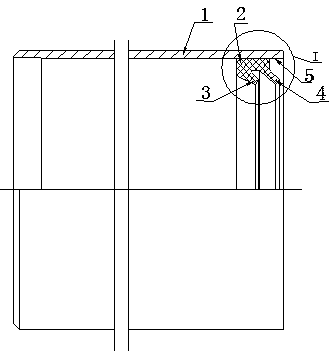

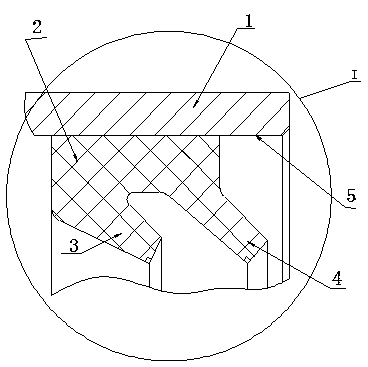

[0016] The present invention as figure 1 , 2 shown.

[0017] The new sealing structure of the transmission shaft sheath, including the transmission shaft sheath 1, is provided with a sealing ring 2 at the outlet of the transmission shaft sheath 1, wherein the outer edge of the sealing ring 2 is provided with a press-fit positioning surface 5 4~6 away from the outlet , the sealing ring is provided with a first lip 3 and a second lip 4 inwardly of the center of the circle. The surface roughness value of the press-fit positioning surface 5 is not greater than 3.2.

[0018] The included angle between the first lip 3 and the second lip 4 and the axial direction of their outer circle is ≤45°.

[0019] The fit between the first lip 3 and the second lip 4 and their inner shaft is an interference fit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com