Valley electricity steam boiler with fused salt heat transfer and heat storage function and method of valley electricity steam boiler for preparing steam

A technology of molten salt and steam, applied in steam boiler components, steam boilers, steam boiler accessories, etc., can solve the problems of high energy costs and achieve high energy storage efficiency, stable pressure, and high operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better explain the present invention, the present invention will be further explained below in conjunction with the examples.

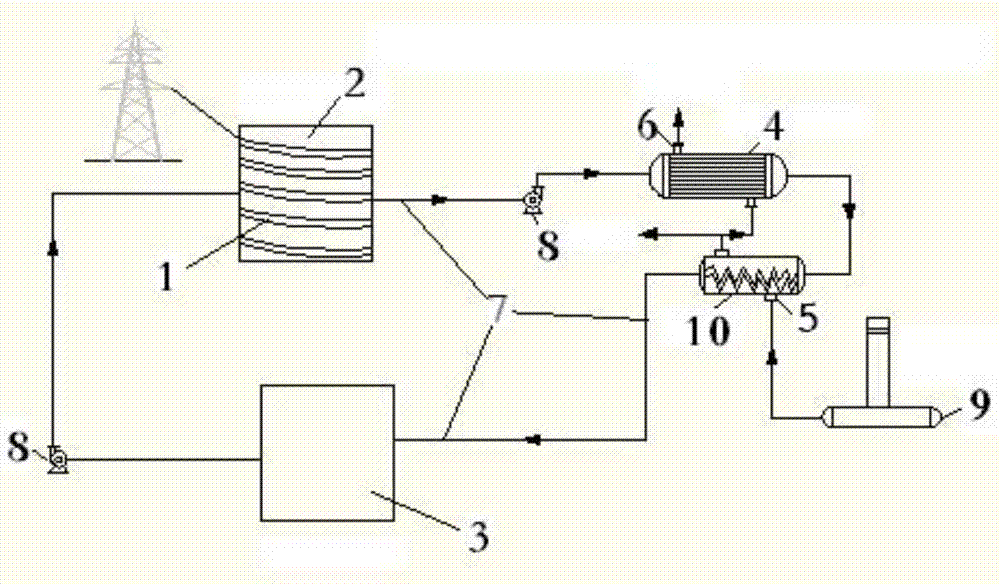

[0034] The valley electric steam boiler for heat transfer and storage of molten salt in this embodiment includes an electrothermal energy storage device, a steam output device, a low-temperature molten salt tank 3 and a heat transfer medium pipeline 7 . The electrothermal energy storage device is a high-temperature molten salt tank 2 wrapped with an electric heat tracing 1 , and the steam output device includes a steam generator 4 and a preheater 10 . The interior of the high-temperature molten salt tank 2 and the low-temperature molten salt tank 3 and the heat transfer medium pipeline 7 are equipped with quartz sand composite molten salts selected from patent application numbers 201310732738.2, 201310040070.5 or 201310040909.5 as heat storage materials and heat transfer media respectively; The preheater 10 includes a water inlet 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com