LED chip mounter

A technology of LED placement machine and placement device, which is applied in the direction of electrical components, printed circuits, printed circuit manufacturing, etc., and can solve the problems of low precision of placement of LED lamp beads, poor flatness of LED light boards, and easy Deformation and other problems, achieve good patch effect, good flatness, and save packaging materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with drawings and embodiments.

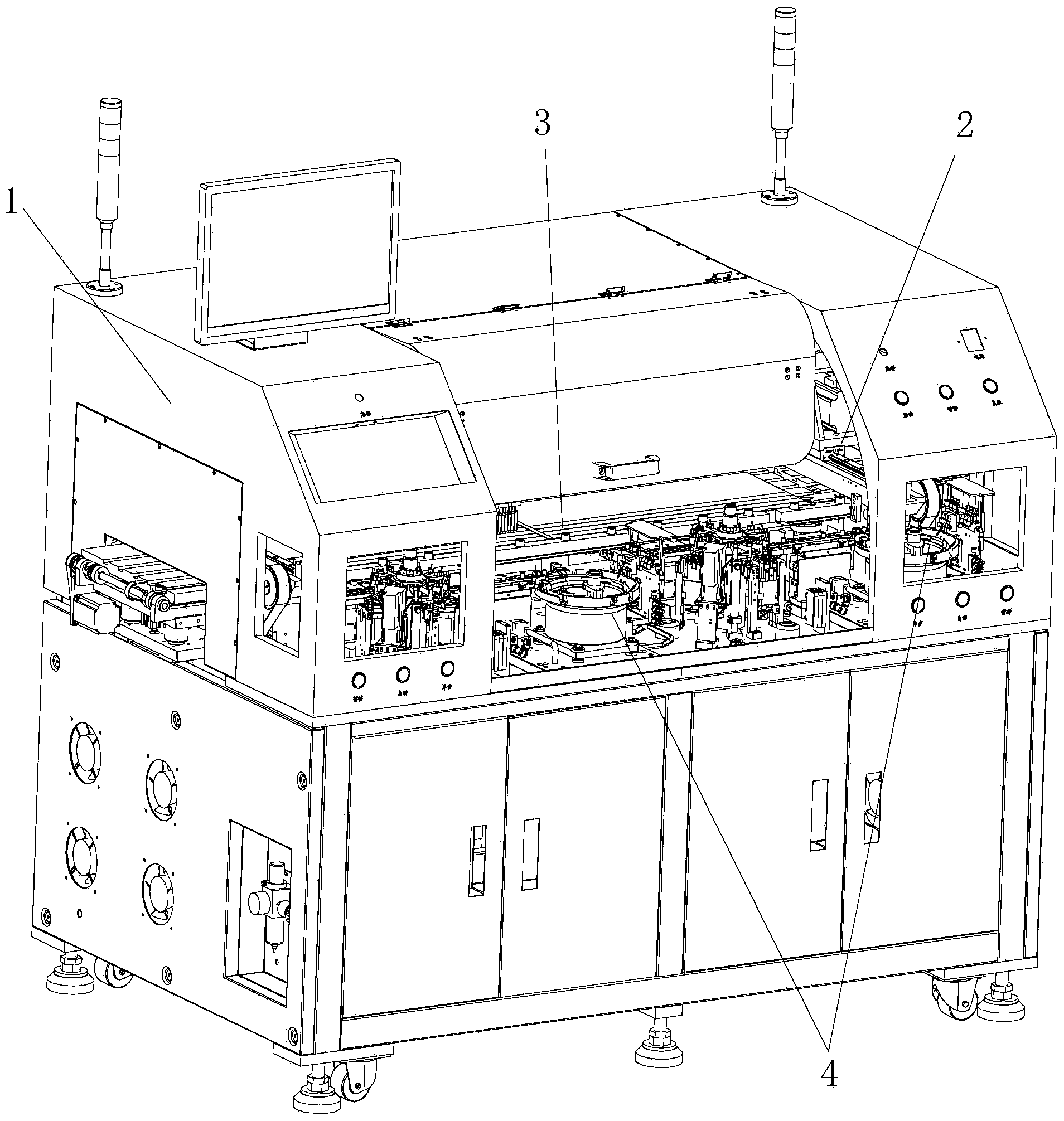

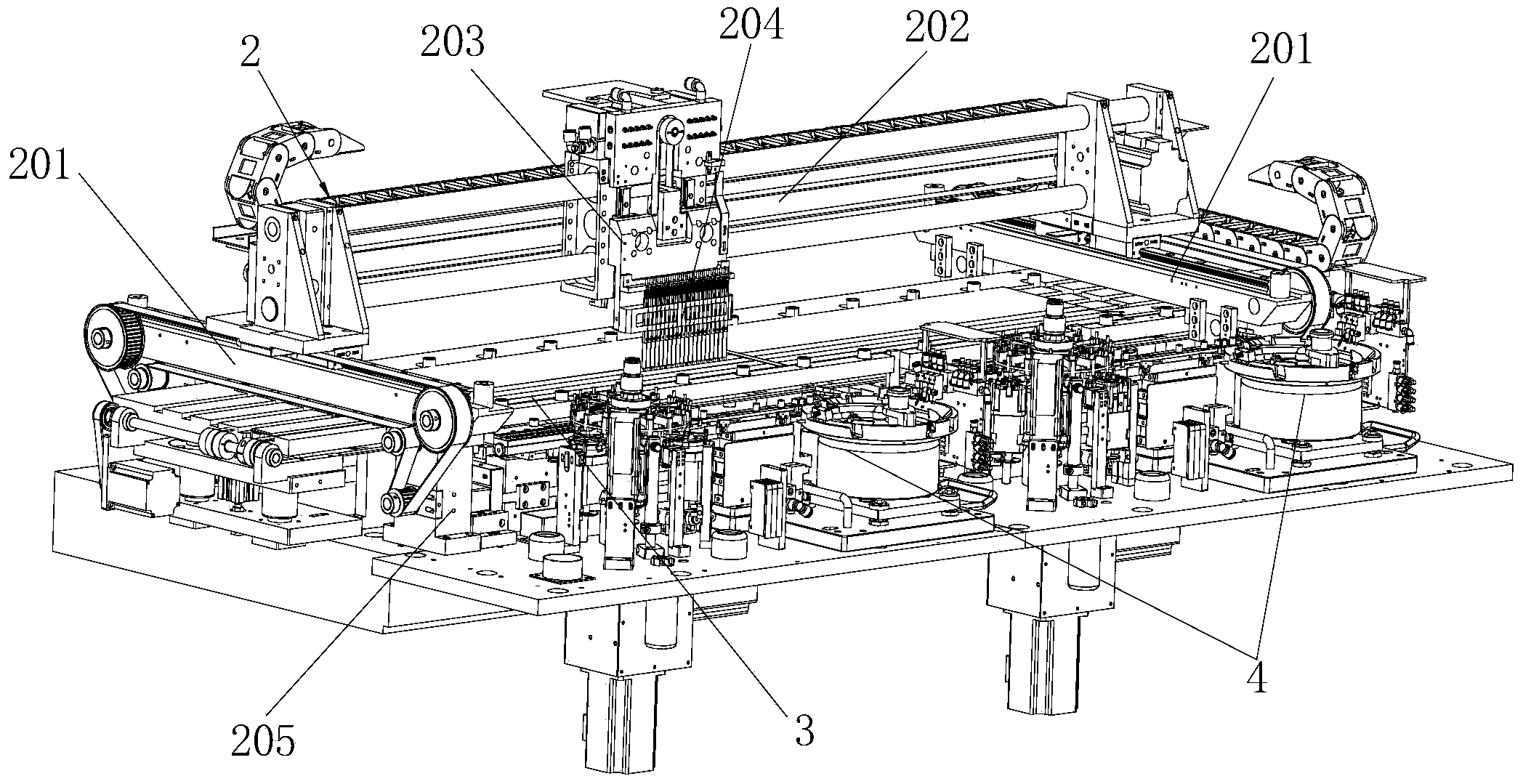

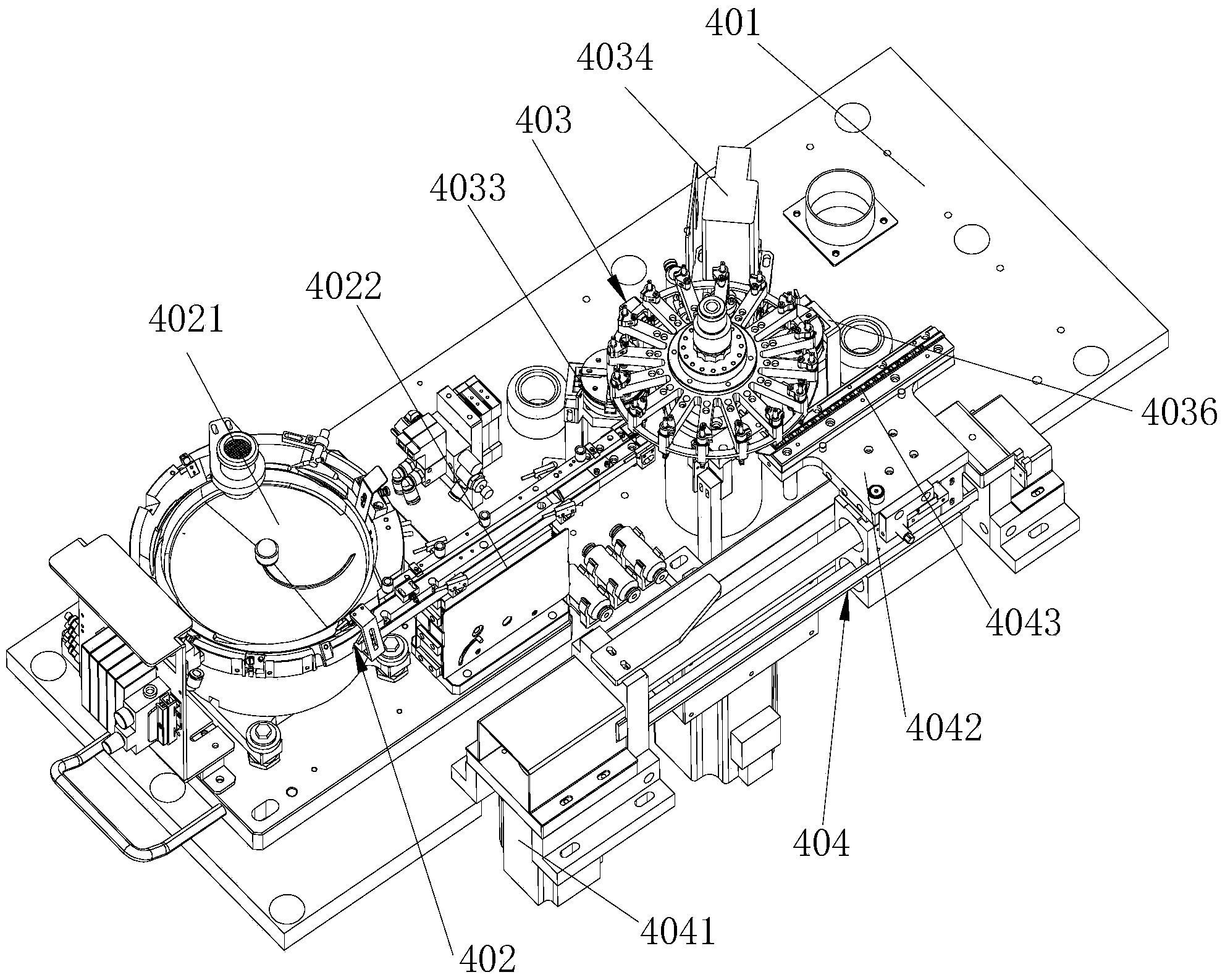

[0046] Such as Figure 1 to Figure 7 The shown LED placement machine includes a body 1, a placement device 2, a lamp board device 3 and at least one set of feeding devices 4, the lamp board device 3 is installed on the rear side of the cabinet 1, and the lamp The two ends of the panel device 3 protrude from the left and right ends of the chassis 1, and the lamp panel device 3 is connected to the patch device 2; the patch device 2 is installed in the chassis 1 and is located above the lamp panel device 3 The feeding device 4 includes a base plate 401, a vibrating plate assembly 402, an indexing plate assembly 403 and a feeding assembly 404, the base plate 401 is installed on the front side in the cabinet 1, the vibrating plate assembly 402, the indexing plate The component 403 and the feeding component 404 are all installed on the bottom plate 401, and the vibrating pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com