Structured surfactant suspending systems

A structured surface, surfactant technology, applied in cosmetics, cosmetic formulations, chemical instruments and methods, etc., can solve the problems of limited visual effect, low attractiveness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

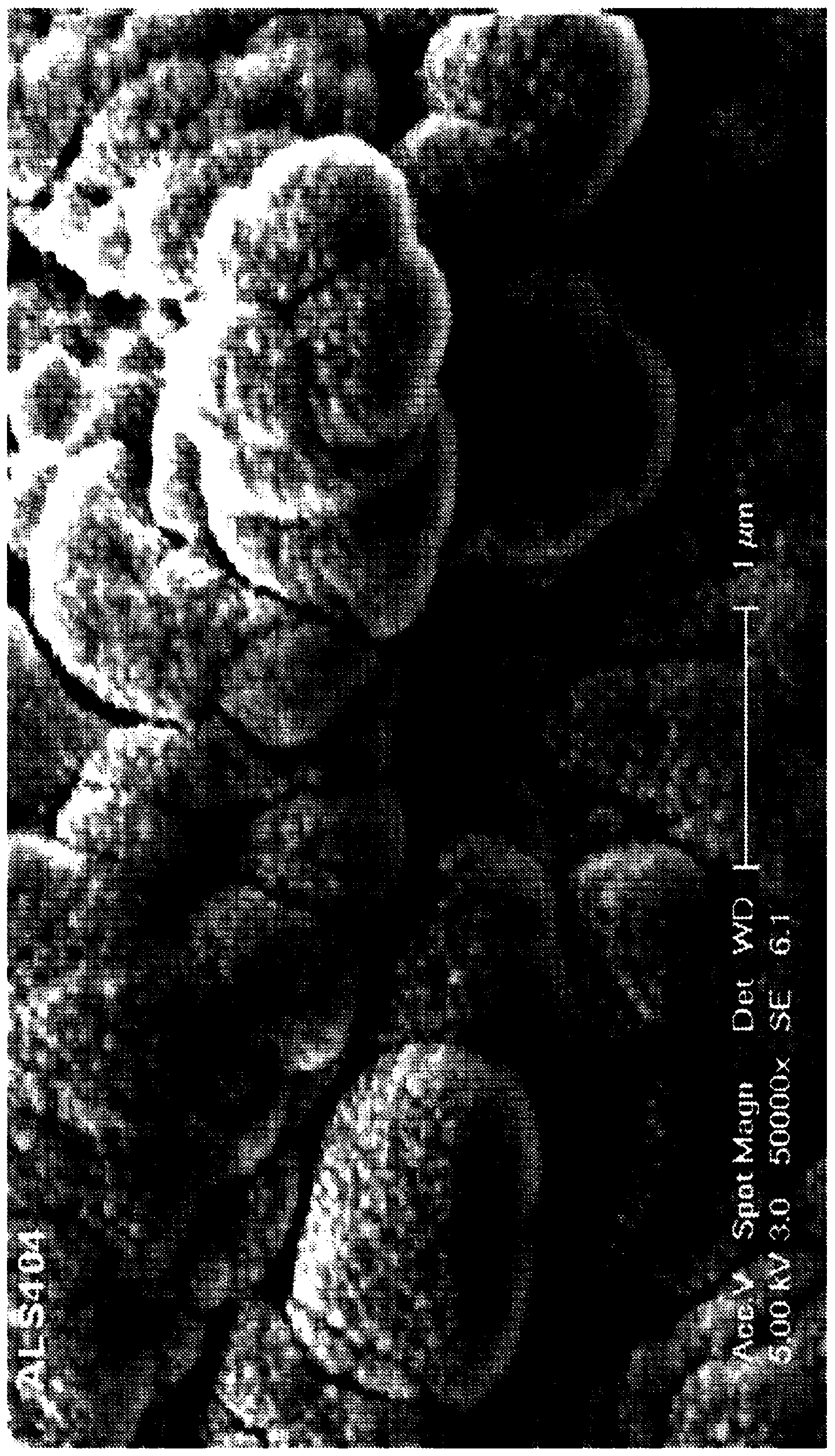

Image

Examples

Embodiment 1

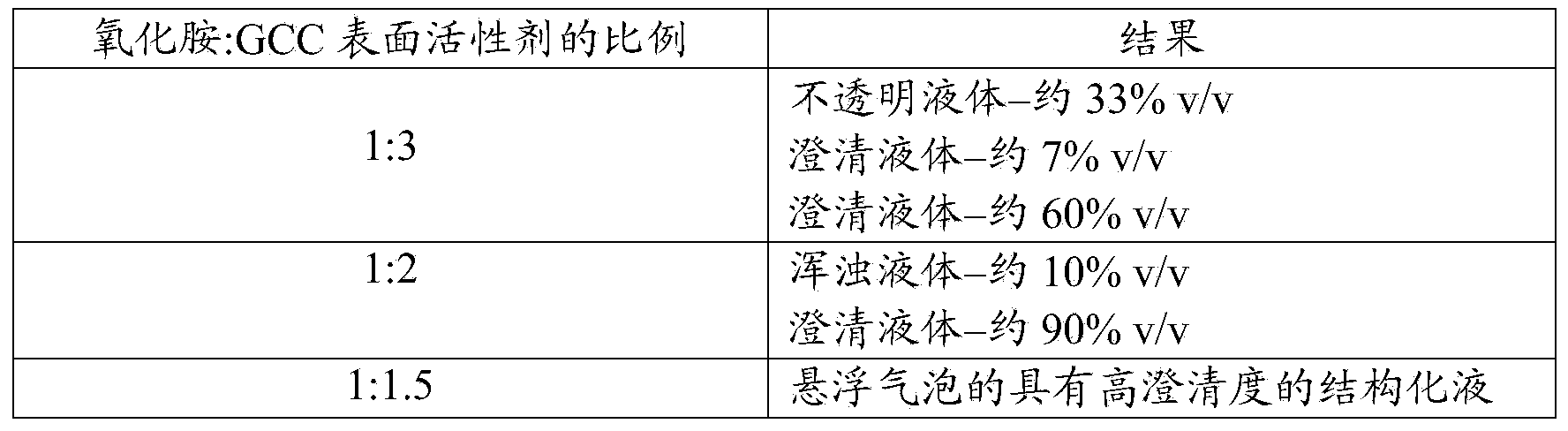

[0050] By mixing amine oxide to caprylic / capric glyceryl in a ratio of 1:3 to 2:1 LO amine oxide and GCC Caprylic Glyceride / Capric Glyceride to prepare a series of formulations. The total surfactant for each formulation was 15 wt%. Table B shows the ratio of each surfactant and the visual results of each formulation.

[0051] Form B: w / w blend of GCC in water (15% total surfactants)

[0052]

[0053]

[0054] A ratio of amine oxide to caprylic / capric glycerides of 1:1.5 to 1.25:1 resulted in structured liquids in which clarity increased with increasing amount of amine oxide. The highest clarity was obtained at 1.25:1 w / w amine oxide: caprylic / capric glyceryl.

Embodiment 2

[0056] Glycerin was added to a 1.25:1 w / w blend of amine oxide: caprylic / capric glycerides to determine whether the added glycerin improved the optical clarity of the blend. Table C shows the formulations prepared with the addition of glycerol.

[0057] Table C: Formulations with added glycerol

[0058]

[0059] The formulation was prepared by hand mixing all components at room temperature, storing overnight at 55°C, stirring again, and cooling to room temperature. All formulations are air-suspended structured liquids. There were significant differences in the clarity of the samples. The sample with 5% glycerol was the clearest with very high clarity, then the sample with 10% glycerol, then the sample with 1% glycerol. These results show that adjusting the refractive index of the continuous phase can improve the clarity of liquid crystal dispersions.

Embodiment 3

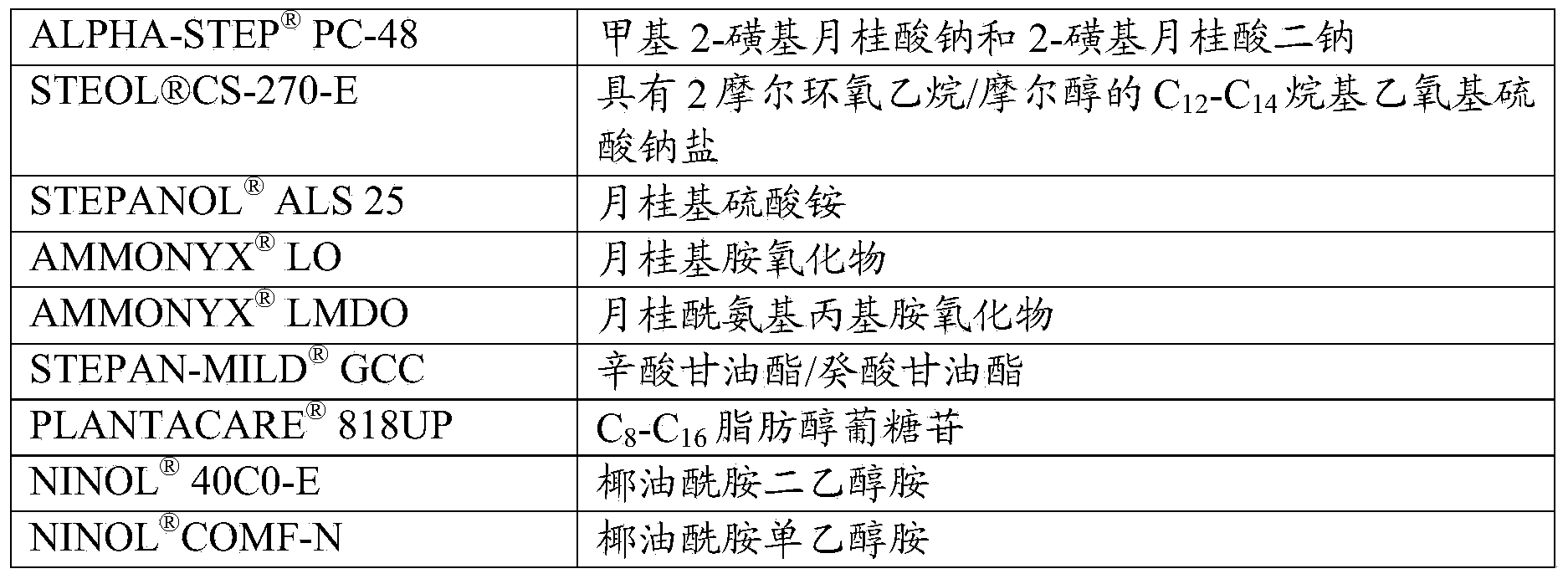

[0060] Example 3: Glyceryl caprylate / glyceryl caprate and other surfactants

[0061] Formulations were prepared by mixing caprylic / capric glyceryl with different hydrophilic surfactants and dispersing in water. Glycerin was added as needed to adjust the refractive index. Different formulations are shown in Table D.

[0062] Form D

[0063]

[0064]

[0065] Formulations were prepared by manually mixing the components together at room temperature, storing overnight at 55°C, stirring again, and then cooling to room temperature. Including GCC with about 3:1 w / w ratio: Sample 2 of PC 48 and about 15 wt% total surfactant provided a strongly structured surfactant suspension system that was only slightly hazy. Sample 3, which included about a 3:1 ratio of GCC:ALS and about 15 wt% total surfactant, also provided a slightly hazy strongly structured surfactant suspension system. Sample 4, which included about a 4:1 ratio of GCC:SLES and about 12.5 wt% total surfactant, was s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com