High-flow anti-bending guide catheter structure

A guiding catheter and high-flow technology, applied in the direction of the catheter, can solve the problems of tissue or dura mater damage, easy discounting, easy blockage, etc., and achieve the effect of solving tissue damage or puncture, reducing damage, and facilitating clinical use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

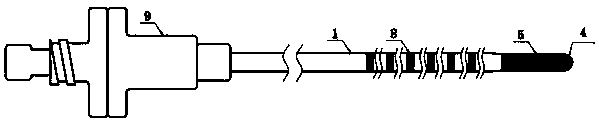

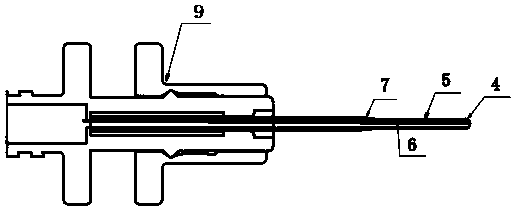

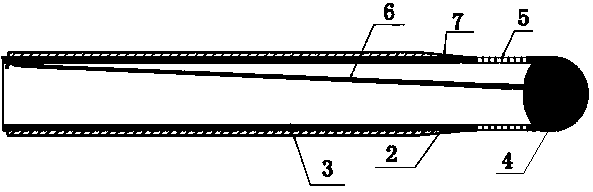

[0026] Such as Figure 1 to Figure 8 A high-flow anti-bending guide catheter structure shown includes a main body 1 , which is a two-layer structure consisting of a spring layer 2 and a polymer material layer 3 . The end of the main body 1 is provided with a stainless steel round head 4 with the main body 1, and an annular gap liquid outlet 5 is provided at the same time, and a fixed flat wire 6 is welded to the round head, and the fixed flat wire 6 passes through the inner diameter of the catheter from the far end to the near One end and the end round head 4 are welded and fixed, and the other end is fixed to the spring layer 2. The length of the flat wire 6 is consistent with the length of the spring layer 2. It not only plays a key role in guiding the entire catheter in use, but also The fixing of the head round head 4 plays a role in supporting the annular liquid outlet. Due to the support of the fixed flat wire 6, when the spring gap liquid outlet 5 is subjected to exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com