Crushing structure of PE particle crushing machine

A pulverizer and crushing technology, which is applied in the field of PE particle pulverizer crushed material structure, can solve the problems of low production efficiency, high equipment cost, complex structure, etc., and achieve the effect of improving production efficiency, reducing production cost and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

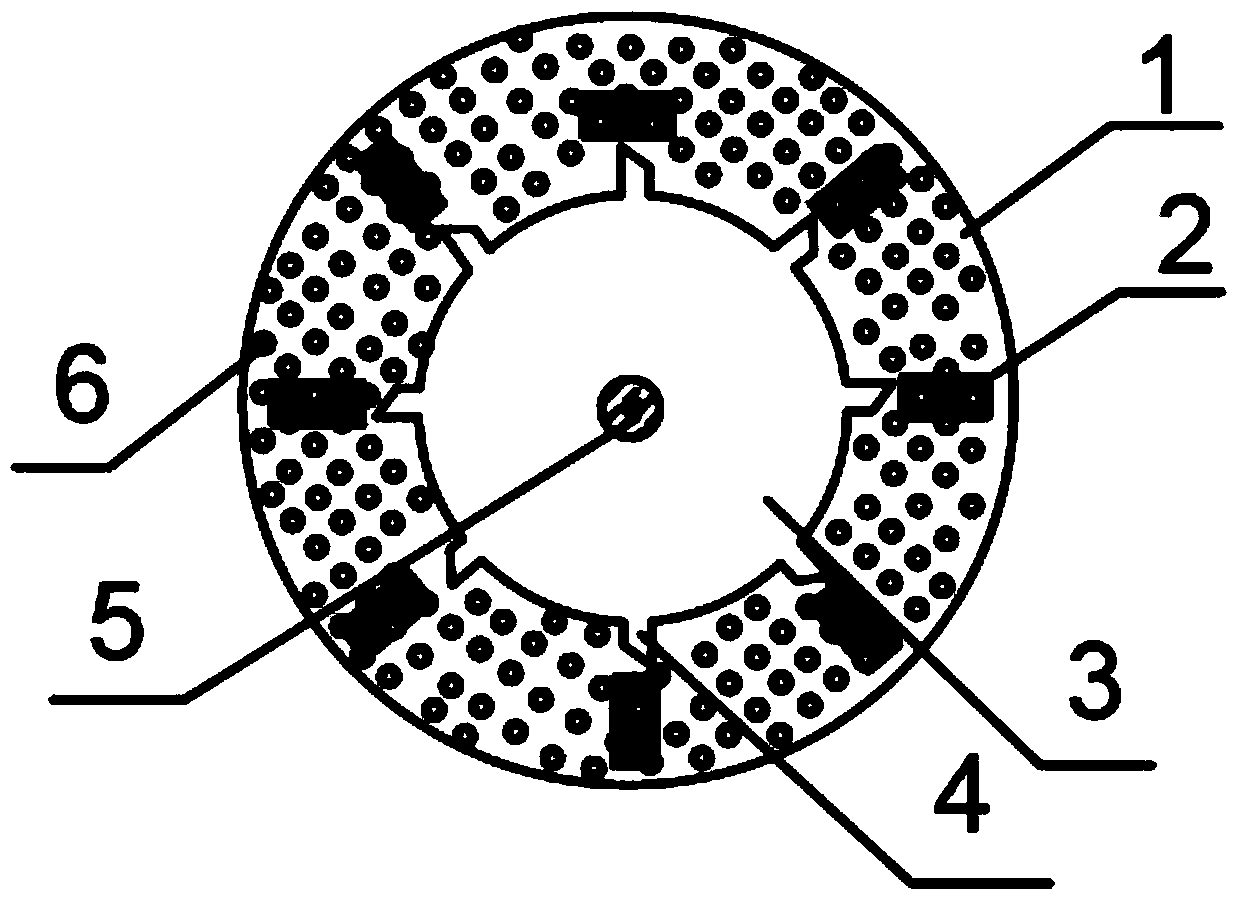

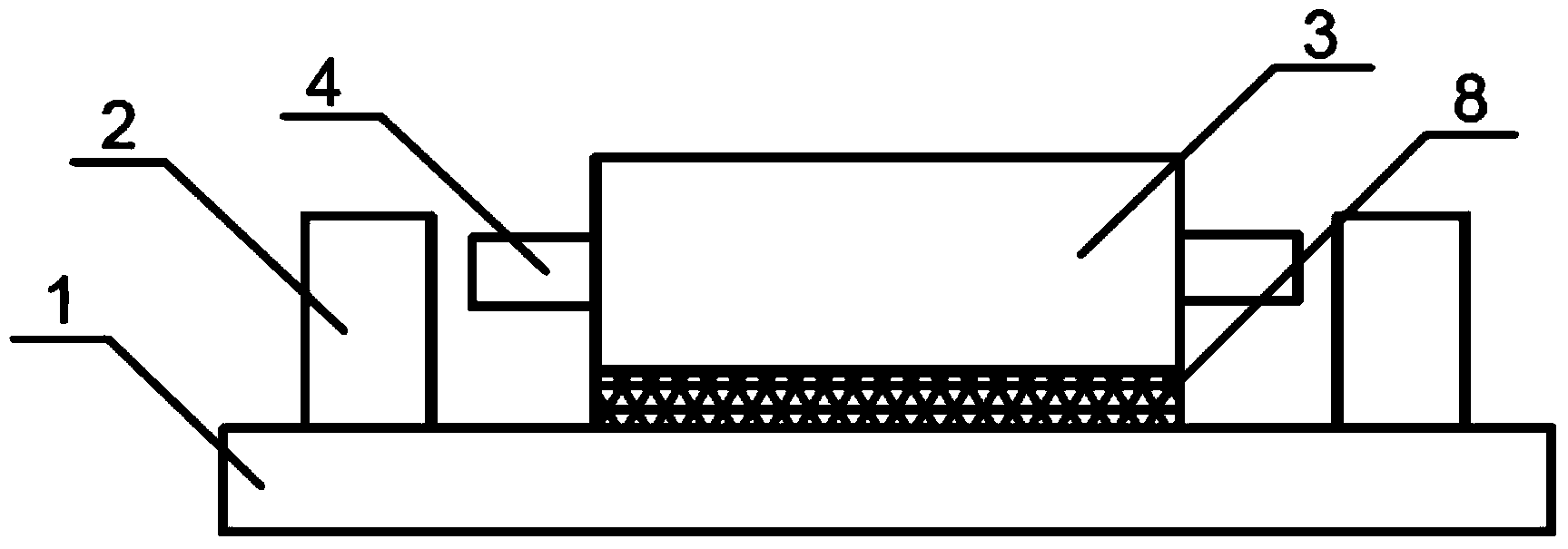

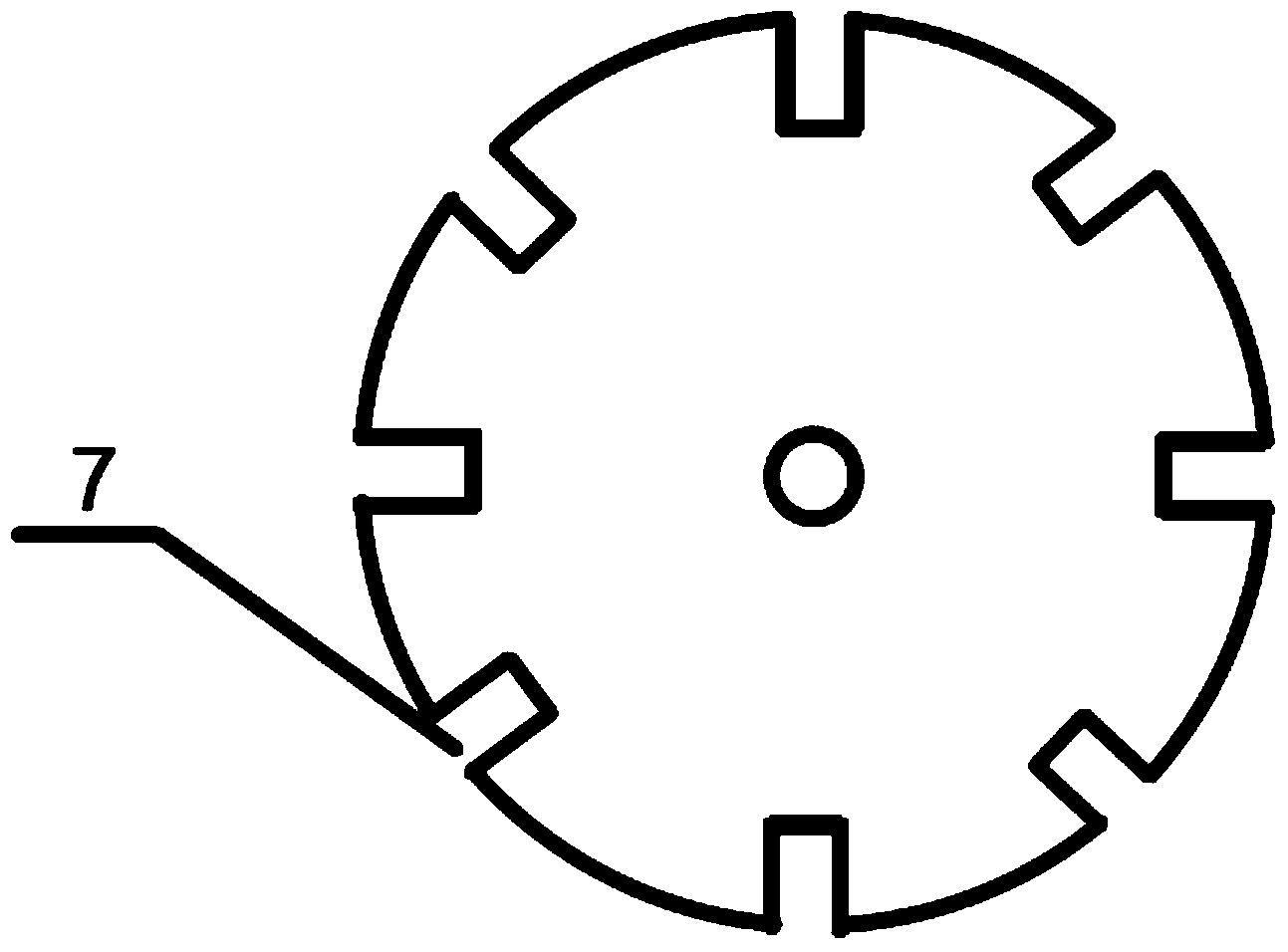

[0018] A best embodiment of the present invention is: as figure 1 , figure 2 As shown, a crushing structure of a PE plastic particle pulverizer according to the present invention mainly includes a fixed knife base 1 on which a positioning hole 6 is drilled; the fixed knife 2 is fixedly connected by the positioning hole 6 and the locking screw. On the fixed knife base 1, change the fixed position of the fixed knife 2 to adjust the distance with the moving knife 4, so as to obtain raw materials with different particle sizes, which will bring convenience to subsequent production; the moving knife 4 is embedded in the bar groove 7 inside, and is fixedly connected to the moving knife holder 3 by locking screws; the rotating shaft 5 is connected to the rotating shaft through a bearing, and the rotating shaft is fixedly connected to the moving knife holder 3, leaving a space between the moving knife holder 3 and the fixed knife base 1 There is a gap; in this embodiment, the bottom ...

Embodiment 2

[0020] Another preferred embodiment of the present invention is: as figure 1 , figure 2 As shown, a crushing structure of a PE plastic particle pulverizer according to the present invention mainly includes a fixed knife base 1 on which a positioning hole 6 is drilled; the fixed knife 2 is fixedly connected by the positioning hole 6 and the locking screw. On the fixed knife base 1, change the fixed position of the fixed knife 2 to adjust the distance between the fixed knife 4 and the moving knife 4, so as to obtain raw materials with different particle sizes, which brings convenience for subsequent production; the moving knife 4 is embedded in the strip groove 7 , and fixedly connected to the moving knife rest 3 through locking screws; the rotating shaft 5 is connected to the rotating shaft through a bearing, and the rotating shaft is fixedly connected to the moving knife rest 3, leaving a space between the moving knife rest 3 and the fixed knife base 1 Gap: In this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com