Spring steel sheet type variable-rigidity gripper assembly and gripper mechanism thereof

A technology of spring steel sheet and variable stiffness, which is applied in the direction of motor vehicles, transportation and packaging, etc. It can solve the problems of small stiffness adjustment range, inconvenient adjustment, difficult secondary grasping, etc., and achieves uniform grasping force distribution and parameter adjustment range Large, stable gripping action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

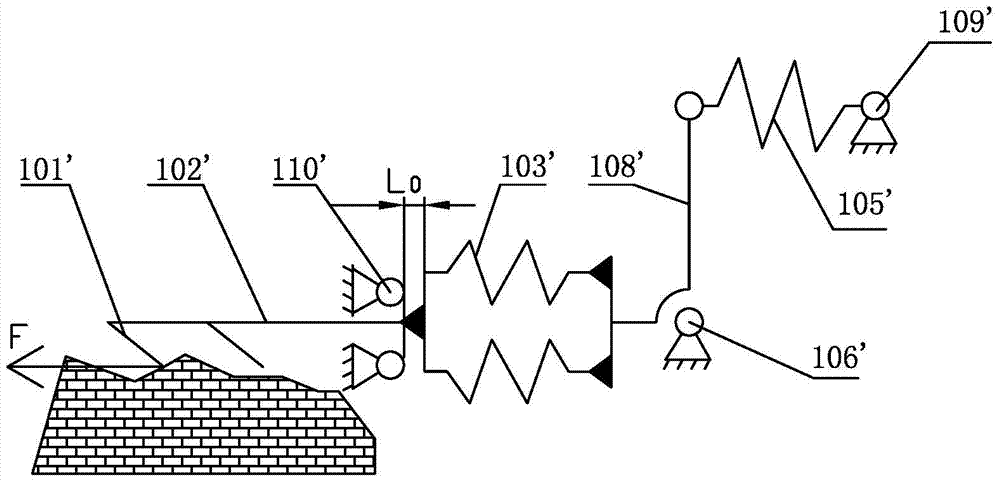

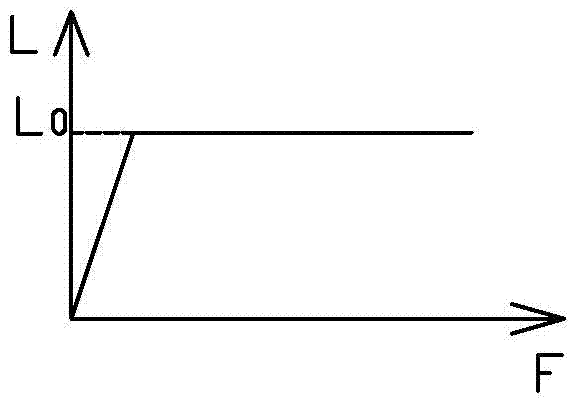

[0035] like image 3 , 4 As shown, the claw assembly of the present invention includes three parts: the claw main body, the connecting frame and the series elastic connection group; wherein:

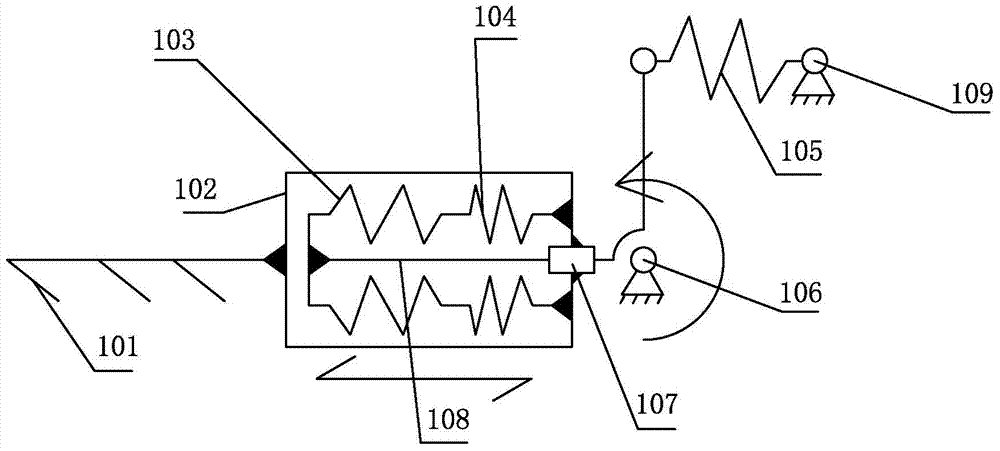

[0036] The claw main body, such as Figure 5 As shown, it is a square frame structure, the lower part is provided with a claw tip 101, and the right side of the square frame is provided with a horizontally arranged opening; the horizontally arranged opening and the inner wall of the box are both used as a guiding working surface for the horizontal movement of the connecting frame;

[0037] The set of elastic connections in series, such as Figure 6 Shown, comprise first spring 103, second spring 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com