A suction type transport tape surface cleaning device and cleaning method

A surface cleaning and tape technology, which is applied in cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of dirty body, high labor intensity, and pollution of the working environment of the tape conveyor, so as to achieve smooth, fast, and lightening of the discharge process. The effect of labor intensity, safe and efficient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is further described:

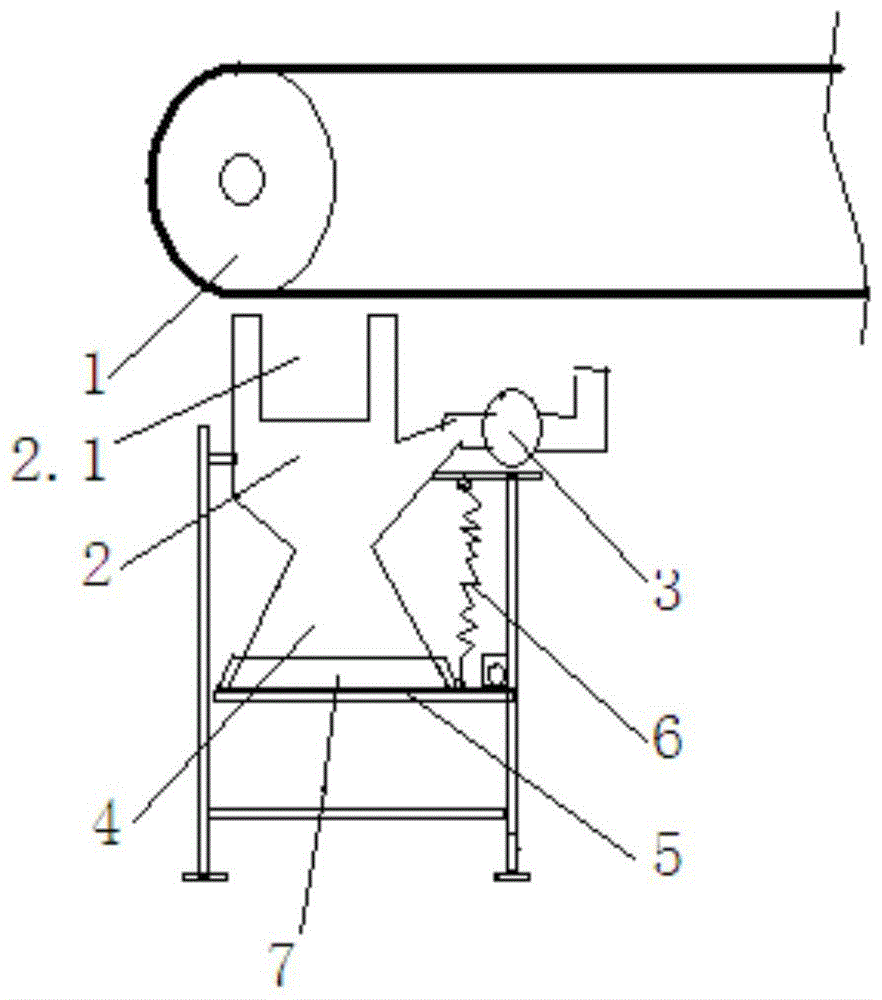

[0018] As shown in the figure, a suction-type conveyor belt surface cleaning device is arranged with a dust suction chamber 2 under the unloading drum 1 of the belt conveyor, and the top surface of the dust suction chamber 2 is designed as a dust suction slot along the width direction of the belt. 2.1, there is a gap of 2-10mm between the dust suction notch 2.1 and the bottom surface of the belt, the dust suction chamber 2 is connected with the dust suction fan 3, and there is a sewage collection container 4 with a certain water storage volume connected to the bottom of the dust collection chamber 2, and the sewage collection container 4 is A circular platform-shaped container with a lower port diameter greater than the upper port diameter. The lower port of the sewage collection container 4 is hinged with a sewage baffle 5, and is tensioned on the lower port of the water collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com