Production method of antistatic surface protection film and antistatic surface protection film

A technology for surface protection film and manufacturing method, applied in the direction of chemical instruments and methods, film/sheet-shaped adhesives, conductive adhesives, etc., to achieve low peeling static voltage, reliable protection, and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

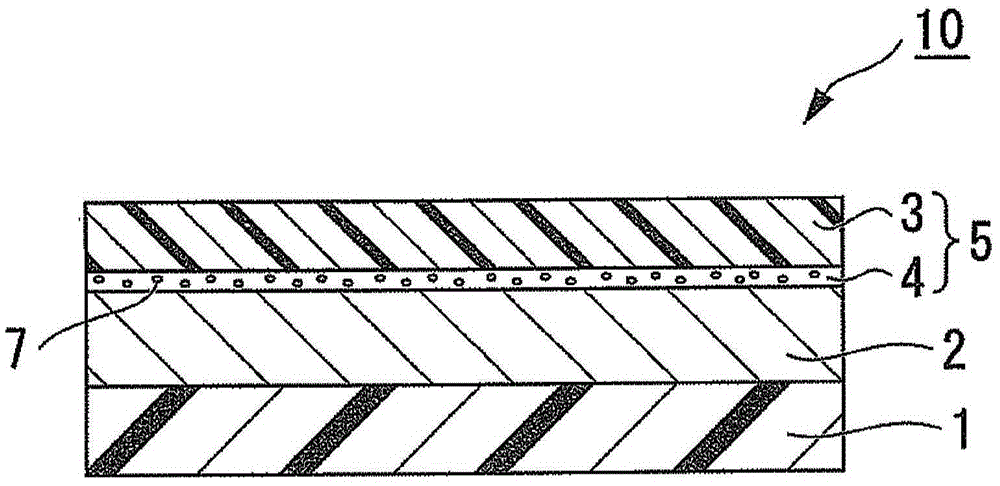

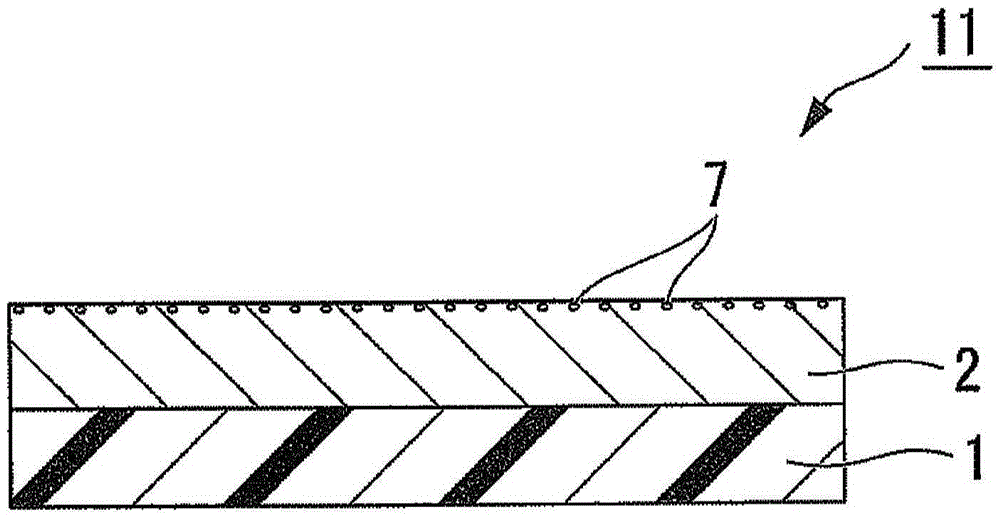

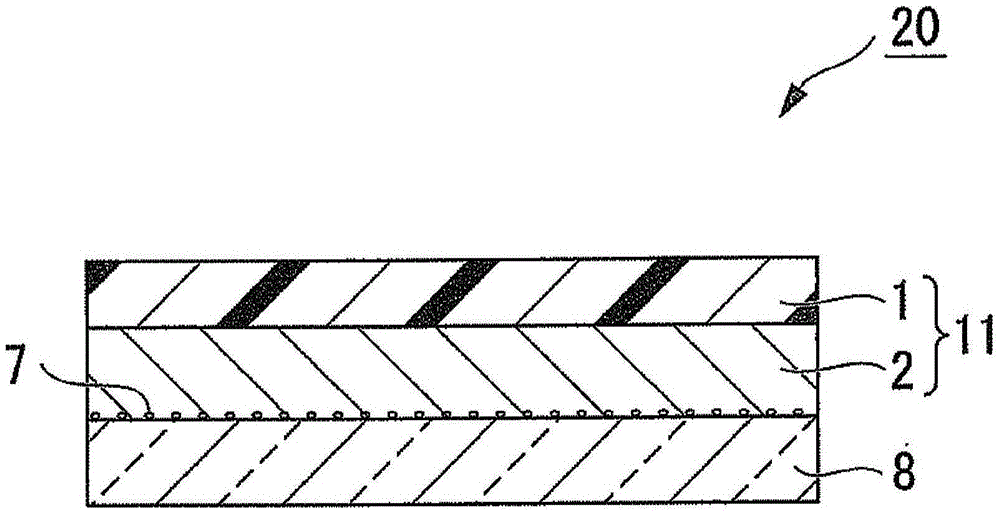

Image

Examples

Embodiment 1

[0091] (manufacture of antistatic surface protection film)

[0092]5 parts by weight of addition reaction polysiloxane (product name is SRX-345, manufactured by Dow Corning Toray Co., Ltd.), 0.15 parts by weight of polyether-modified polysiloxane Siloxane (product name is SH8400, manufactured by Dow Corning Toray Co., Ltd.), lithium perchlorate of 5 parts by weight is 10% ethyl acetate solution, toluene of 95 parts by weight and ethyl acetate are 1:1 Mixed solvent and 0.05 parts by weight of platinum catalyst (product name is SRX-212Catalyst (catalyst), manufactured by Dow Corning Toray Co., Ltd.) are mixed together and stirred and mixed to prepare the coating that forms the release agent layer of embodiment 1 . Using a Meller rod, the paint forming the release agent layer of Example 1 was coated on the surface of a polyethylene terephthalate film with a thickness of 38 μm so that the thickness after drying was 0.2 μm, and It dried for 1 minute in the hot-air circulation ove...

Embodiment 2

[0094] The antistatic surface protection film of Example 2 was obtained in the same manner as in Example 1 except that the thickness after drying of the paint forming the release agent layer of Example 1 was 0.1 μm.

Embodiment 3

[0096] As the addition reaction polysiloxane of Example 1, a product named SRX-211 manufactured by Dow Corning Toray Co., Ltd. (DowCorning Toray Co., Ltd.) was used. As the polyether-modified polysiloxane A product named KS-352A manufactured by Shin-Etsu Chemical Co., Ltd. was used, and 10 parts by weight of lithium bis(trifluoromethanesulfonyl)imide in 10% ethyl acetate solution was used instead of 5 parts by weight of perchloric acid Lithium is a 10% ethyl acetate solution, and the antistatic surface protection film of Example 3 was obtained in the same manner as in Example 1 except for the above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com