Concrete pile construction method

A construction method and technology of concrete piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as difficulty in forming the design depth of pile holes, impossibility of further construction, and water inflow into pile holes, etc., achieving fast and applicable The effect of wide range and fast hole forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

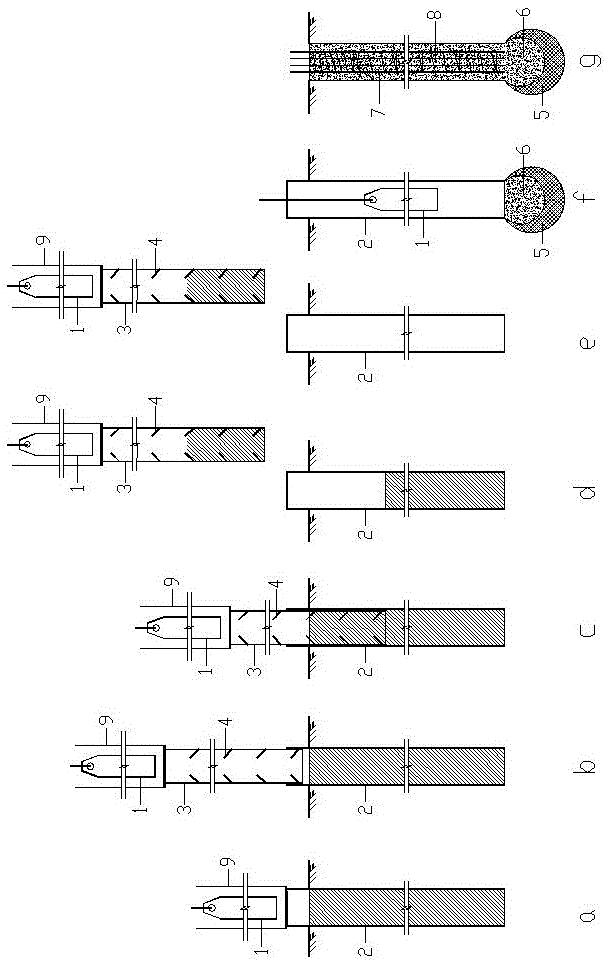

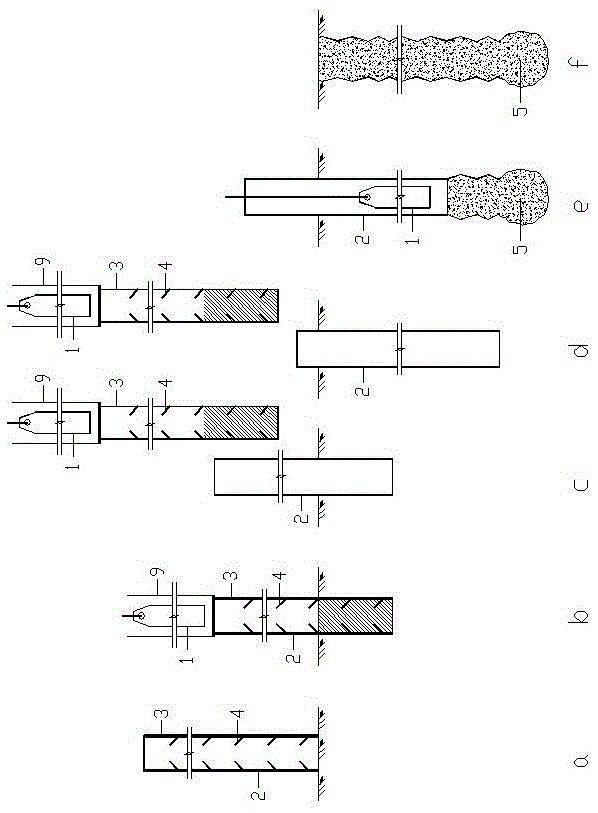

[0037] figure 1 It is a process diagram of an embodiment of the construction method of concrete pile of the present invention, and it comprises the following steps, at first, as figure 1 As shown in a, through the lifting and lowering of the weight 1 in the tamping sleeve 9, the hammering outer pipe 2 sinks downward in the soil until it reaches the design depth; then, as figure 1 As shown in middle b, a special inner tube 3 is placed in the outer tube 2, and the inner wall of the inner tube 3 has a plurality of upwardly inclined barbs 4; then, as figure 1 As shown in c, through the lifting and lowering of the weight 1 in the tamping sleeve 9, the hammered inner tube 3 punches the soil inside the outer tube 2 and sinks, and the soil contained in the original outer tube 2 is punched and squeezed into the into the inner tube 3; then, as figure 1 As shown in middle d, after the inner pipe 3 sinks to a certain depth, the inner pipe 3 is lifted out of the outer pipe 2. Due to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com