Underwater concrete spouting laitance prevention water-proof device

An underwater concrete and anti-floating technology, applied in construction, infrastructure engineering and other directions, can solve the problems of the influence of concrete strength, insufficient concrete strength, influence of concrete thickness, etc., to shorten the construction period, simplify the construction, and ensure the effect of concrete strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

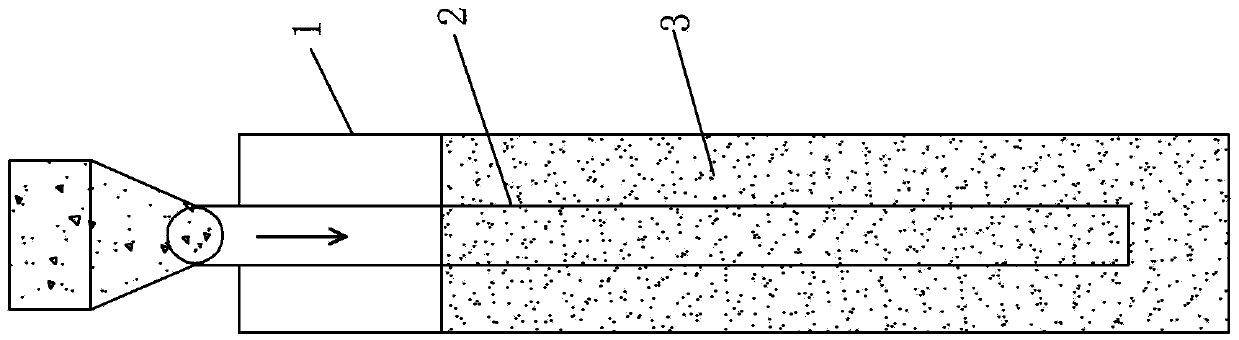

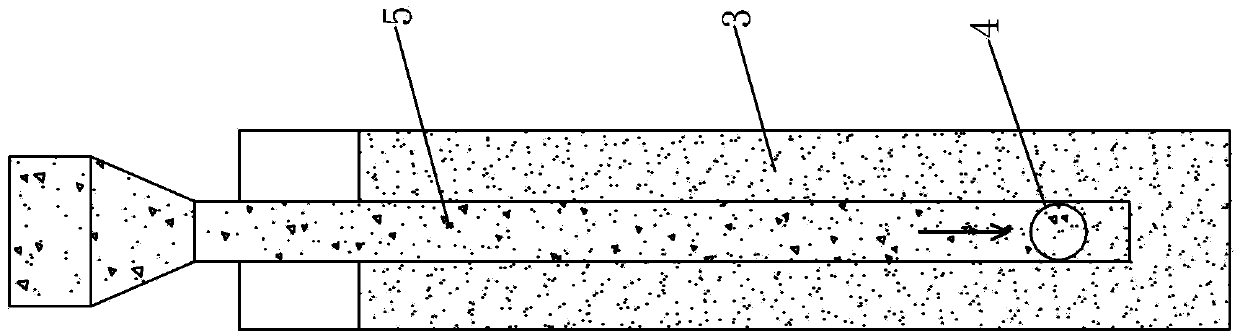

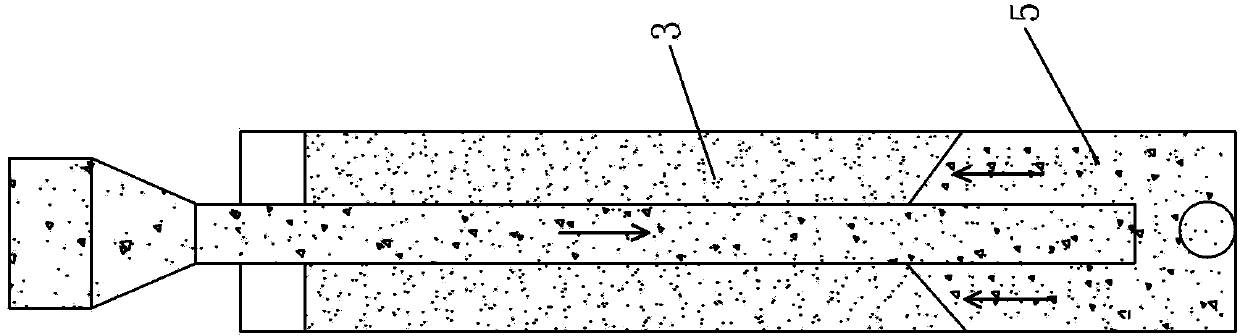

[0029] Such as Figure 5 to Figure 9 As shown, the underwater concrete pouring anti-floating slurry water-retaining device of the present invention includes an annular water-repelling plate, a rubber barrier ring, an elastic brush 15 and an air bag, and the annular water-repelling plate is arranged on the pouring conduit 2 outside and the inner wall of the reinforcement cage (not shown in the figure) in the pile body 1, the rubber barrier ring is arranged on the inner side of the inner ring of the annular water baffle and sleeved on the outer wall of the pouring conduit 2, and the elastic brush 15 is uniform Connected to the outer circumference of the annular water baffle and extend from the outer circumference of the annular water baffle to the outer wall of the pile body 1, the elastic brush 15 is made of hard plastic, the outer edge of the annular water baffle is connected with a side rib 14, and the elastic brush 15 evenly connected to the side ribs 14. The air bag is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com