Construction technology of prestressed oblique beam with variable cross-section

A construction technology and prestressing technology, applied in the direction of joists, girders, trusses, etc., can solve the problems of corrugated pipes not being able to be threaded, unfavorable for concrete pouring, bending, etc. The effect of prestressing pollution and ensuring beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to better understand the present invention, the content of the present invention will be further clarified below in conjunction with the engineering embodiment of the 15,000-seat main stadium of Wuhan Optics Valley International Tennis Center, but the content of the present invention is not limited to the following examples.

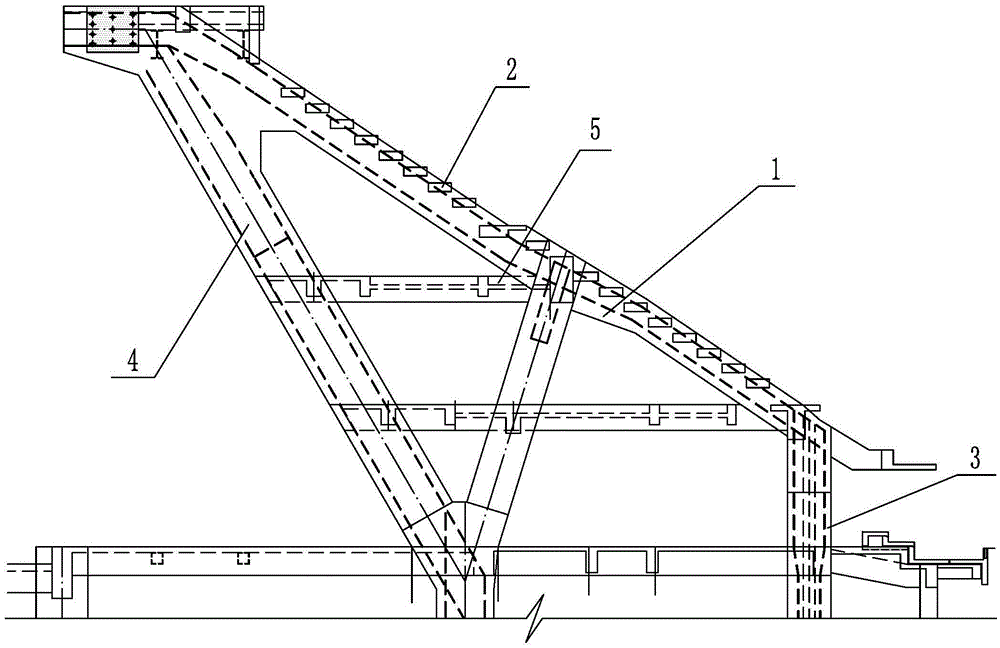

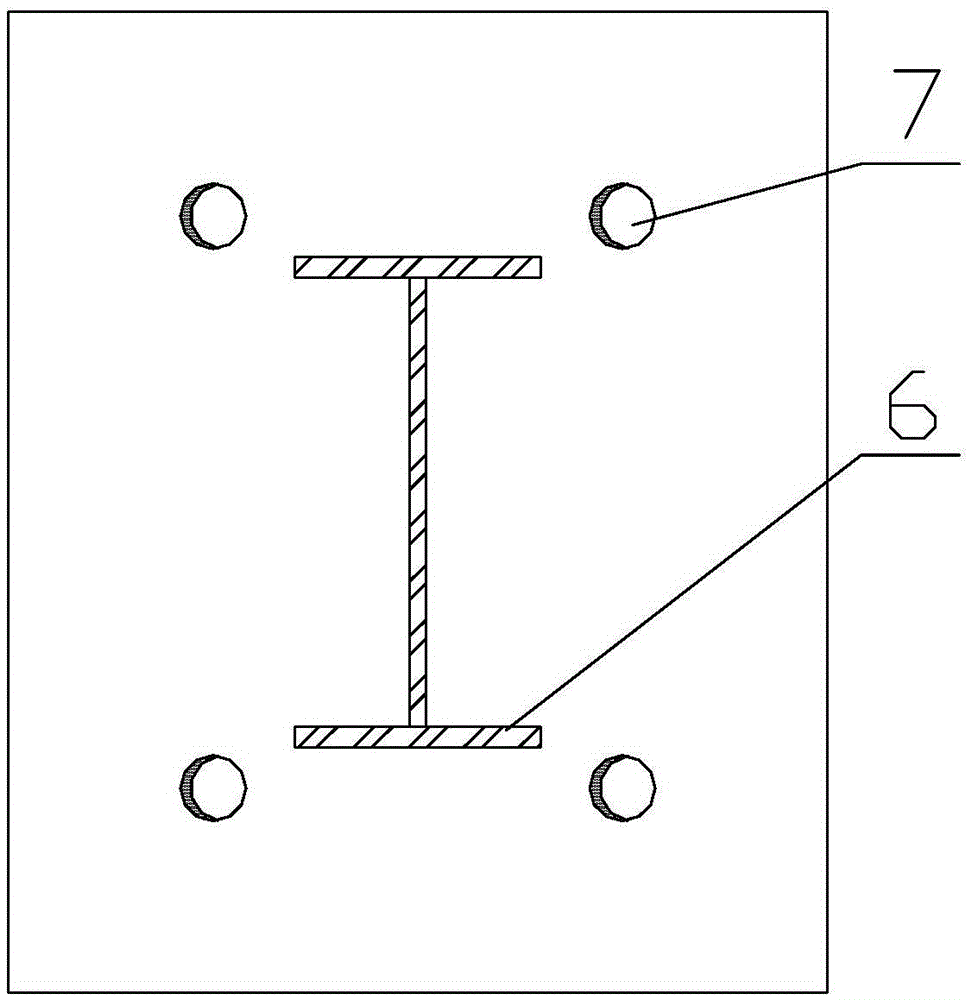

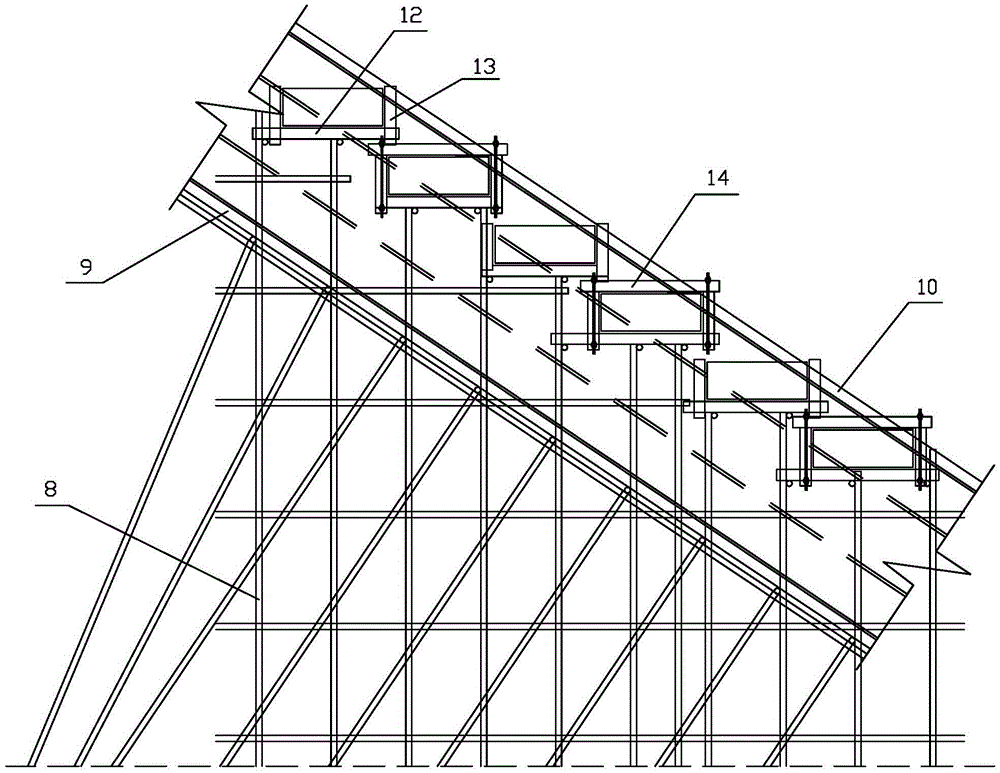

[0050] Such as Figure 1-5As shown, the variable cross-section prestressed inclined beam mainly includes the inclined beam body 1 (length 29.5m), the lower end of the inclined beam body 1 is connected with the upper end of the first-floor column 3 by pouring, and the middle and upper ends of the inclined beam body 1 are connected with the Y-shaped column 4. Pouring connection; both sides of the inclined beam body 1 (along the length direction) and the inclined beam body are poured with picking ears (several picking ears are symmetrically provided) 2; the picking ears 2 (upper right corner) are higher than the A certain distance (such as 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com